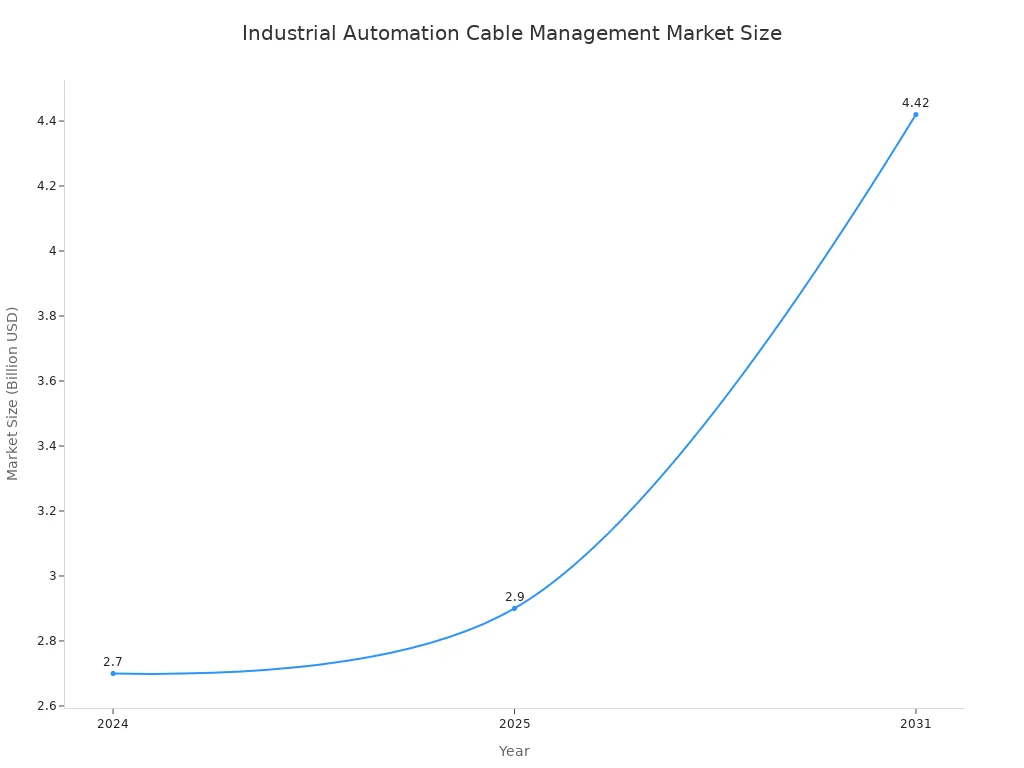

Self-locking stainless steel cable ties are quickly becoming essential for industrial automation’s future. You will find their unparalleled durability, reliability, and adaptability crucial in demanding environments. The industrial automation cable management market shows significant growth. It is projected to reach $4.42 billion by 2031.  This growth emphasizes the need for robust solutions like self-locking stainless steel cable ties.

This growth emphasizes the need for robust solutions like self-locking stainless steel cable ties.

Key Takeaways

- Self-locking stainless steel cable ties are very strong. They last a long time. They work well in tough factory conditions.

- These ties keep cables safe. They stop fires. They meet important safety rules for machines.

- Using these ties saves money. They need less fixing. They make sure machines run without stopping.

The Demands of Industrial Automation: Why Traditional Cable Management Falls Short

Harsh Operating Environments Challenge Cable Integrity

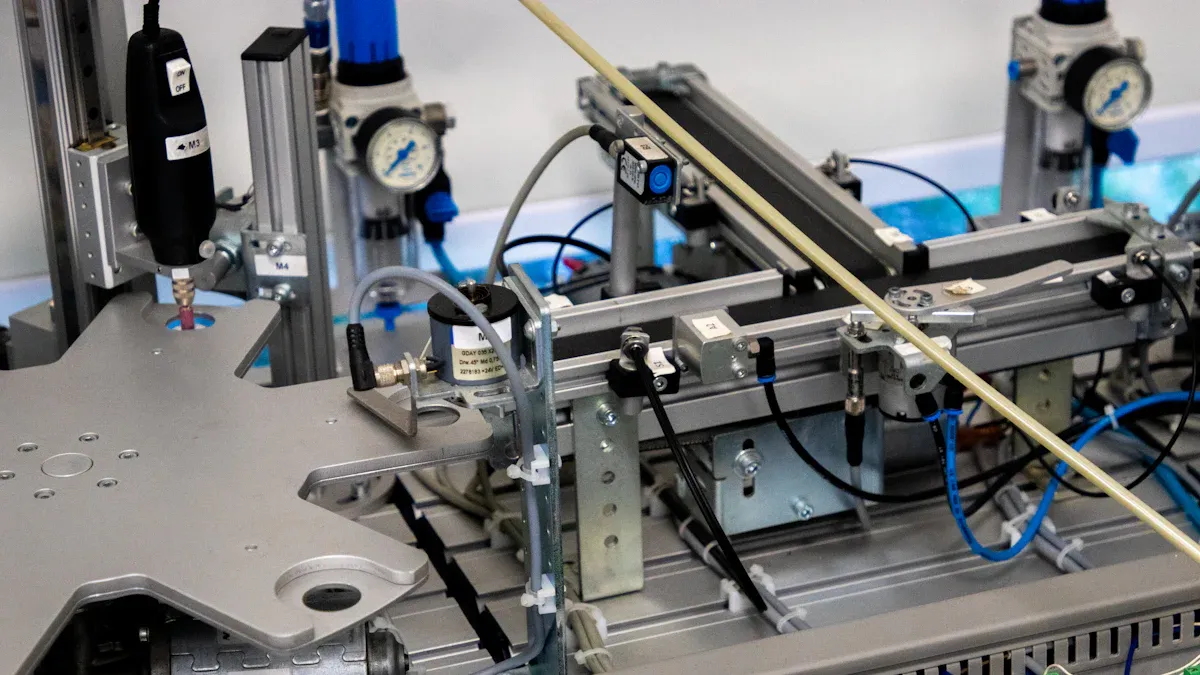

Industrial automation systems face constant challenges. You often find them in environments with significant electromagnetic interference (EMI). Motors, power lines, and other equipment generate this interference.

Industrial environments are often rife with electromagnetic interference from motors, power lines, and other equipment. Bus cables are designed with shielding and insulation to protect the transmitted data from EMI, ensuring a reliable and stable communication network.

Traditional cable management struggles to protect data integrity in these conditions. You need robust solutions to prevent signal degradation.

Critical Reliability and Uptime in Automated Systems

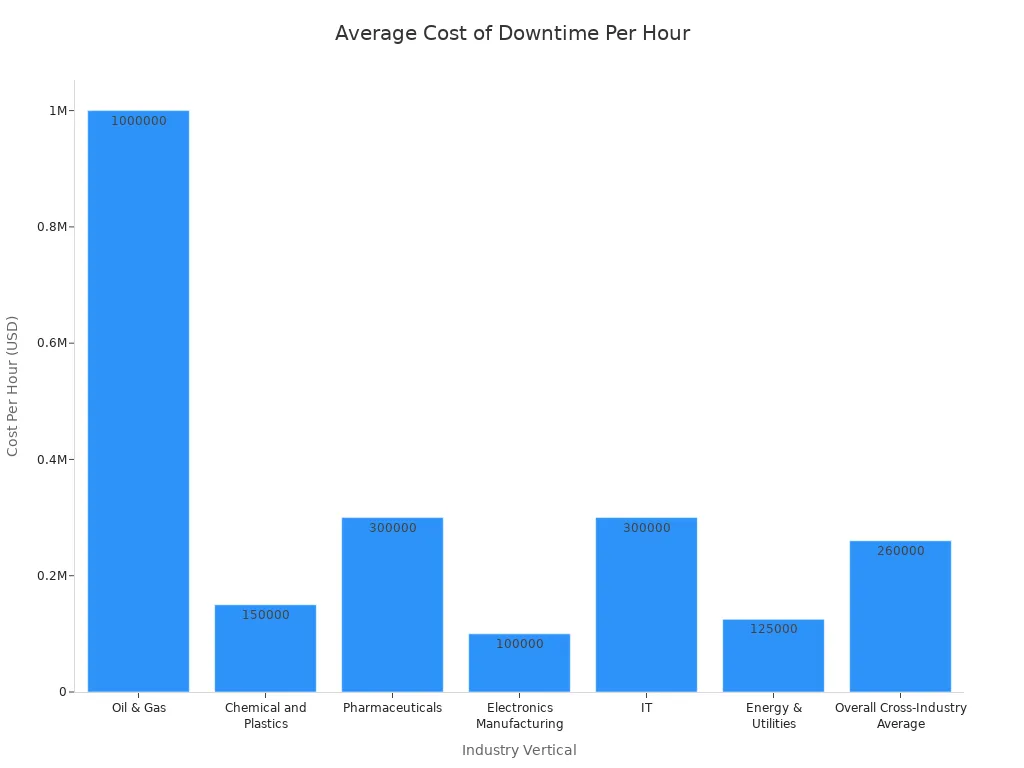

Reliability is paramount in automated systems. Downtime can be incredibly costly for your operations. More than 70% of all network faults in industrial automation stem from network components and media. Cables are a primary part of this media. This directly reflects issues with cable integrity.

Consider the financial impact. In light manufacturing, downtime can cost approximately $250,000 per hour. For the energy sector, this cost can reach up to $2.5 million for a single hour.

| Industry Vertical | Cost Per Hour of Downtime |

|---|---|

| Oil & Gas | ~$1,000,000 |

| Chemical and Plastics | ~$150,000 |

| Pharmaceuticals | $100,000 – $500,000 |

| Electronics Manufacturing | $100,000 or more |

| IT | >$300,000 |

| Energy & Utilities | ~$125,000 |

| Overall Cross-Industry Average | $260,000 |

Cable management issues frequently cause this downtime.

- Cables can tangle if they lack interior separation.

- Uneven weight distribution can disrupt movement.

- An overfilled cable carrier obstructs free movement.

- Lack of proper strain relief leads to premature system failure.

- Incorrect cable positioning causes problems.

- Different jacket types placed together can cause wear.

- Incorrect cable carrier length compromises movement.

Space Constraints and Complex Cable Routing

Modern industrial setups often have limited space. You frequently need to route new cables near noise-generating equipment. This happens especially during factory upgrades. Traditional cable management systems struggle with these tight, complex routing demands. They often cannot provide adequate protection or organization.

Unpacking the Advantages: Why Self-Locking Stainless Steel Cable Ties Excel

Superior Durability and Longevity of Self-Locking Stainless Steel Cable Ties

You need cable management solutions that withstand the toughest industrial conditions. Self-locking stainless steel cable ties offer superior durability and longevity. Their material properties make them exceptionally robust. Stainless steel resists corrosion, especially pitting and crevice corrosion. This resistance comes from a chromium-rich oxide layer. This layer acts as a protective barrier against environmental deterioration from air and water. Stainless steel also boasts high tensile strength. This property allows it to endure significant pressure and temperature without deforming. It maintains structural integrity under heavy loads.

You will find certain grades of stainless steel ductile and formable. This means you can shape them into complex forms without compromising their integrity. This offers manufacturing flexibility. Stainless steel also maintains its strength and stability at high temperatures, making it suitable for industrial furnaces. Its capacity to withstand high temperatures and retain structural integrity during fires makes it a safe material for fire-prone environments. Some stainless steel grades even exhibit good ductility at extremely low temperatures. This makes them suitable for applications in cold regions or with liquefied natural gases. Chromium, nickel, molybdenum, and nitrogen are key elements that enhance stainless steel’s overall performance.

Self-locking stainless steel cable ties significantly outperform traditional alternatives in lifespan.

| Cable Tie Type | Typical Lifespan (Harsh Industrial Conditions) |

|---|---|

| Self-locking Stainless Steel | 10-30 years (regularly exceeds 10 years) |

| Traditional Nylon | 1-2 years |

Unlike plastic alternatives, which become brittle and crack in harsh industrial environments, stainless steel cable ties maintain their tensile strength and flexibility. This inherent material property allows them to consistently outperform other options and last significantly longer. You can expect self-locking stainless steel cable ties to last 8-10 years in tough conditions, while plastic alternatives typically last only 18-24 months.

Unmatched Security with Self-Locking Mechanisms

You need secure cable management in automation. Self-locking stainless steel cable ties provide unmatched security. They use a rolling ball mechanism within the buckle. When you thread the tie’s tail through the head, the ball rolls inward, following the direction of the tie. As you tighten the tie to the desired position and release it, the tie exerts an outward pull. This outward pull causes the ball to roll back slightly. The ball then wedges, securing the tie in place and preventing it from loosening. This design is irreversible, ensuring a permanent and secure hold.

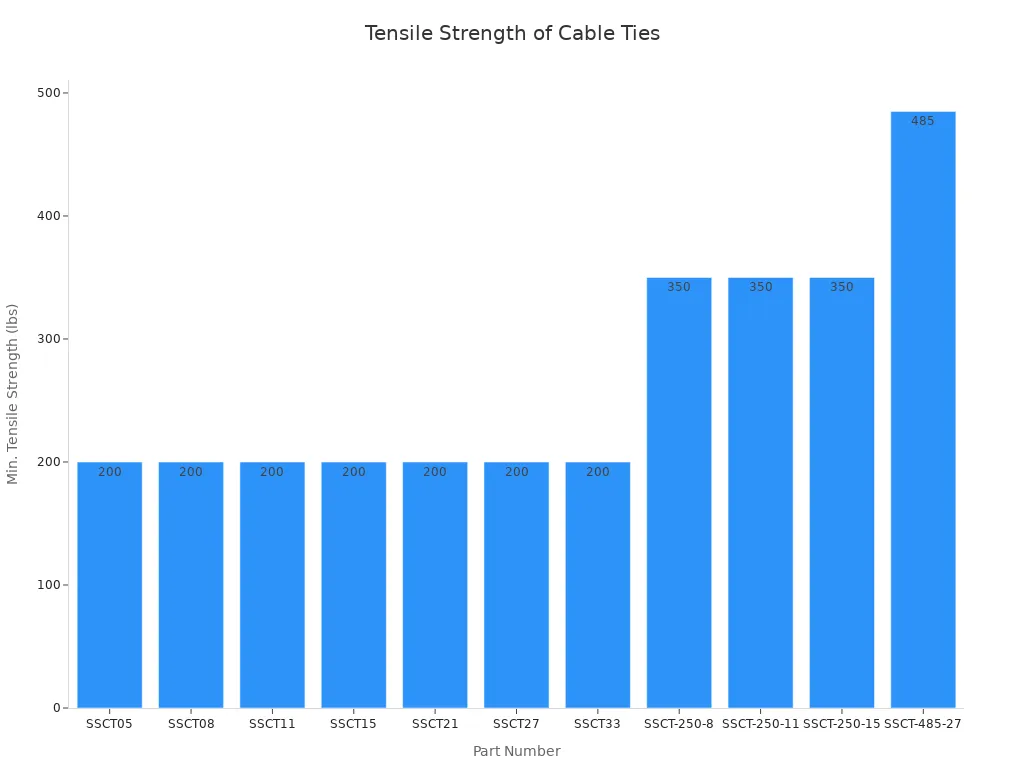

This robust locking mechanism provides exceptional tensile strength. You can see the impressive strength of these ties:

For example, Panduit self-locking 304 stainless steel cable ties offer a minimum loop tensile strength of 200 lbs. Electriduct 304 stainless steel cable ties provide tensile strengths ranging from 175 to 250 lbs. This high tensile strength ensures your cables remain securely bundled, even under significant stress or vibration.

Enhanced Safety and Compliance in Automation

You must prioritize safety in industrial automation. Self-locking stainless steel cable ties significantly contribute to reducing fire hazards. They withstand heat up to 1000°F and are both corrosion- and fire-resistant. They also offer higher tensile strength and a longer life, enhancing overall safety.

These ties are essential for bundling cables in high-temperature, high-pressure environments, such as oil and gas facilities. They enhance safety through their fire resistance and mechanical strength. Stainless steel cable ties are crucial for securing safety devices like fire alarms, emergency shutdown systems, and gas detectors in these facilities. Their proper installation and positioning, ensured by these ties, significantly contribute to overall facility safety and worker protection. Their corrosion resistance and high strength make them reliable components in demanding safety infrastructures.

Stainless steel cable ties comply with stringent safety regulations. This makes them vital for critical applications in industrial and mining operations. They excel in harsh environments due to their high tensile strength and resistance to extreme temperatures, chemicals, and mechanical stress. Their flame-retardant properties and ability to resist weathering are particularly beneficial in mining. They secure heavy-duty equipment and wiring in factories. They remain reliable in temperatures as high as 176°F (85°C) and as low as -40°F (-40°C), making them suitable for fire-prone areas.

Versatility Across Diverse Automation Applications

You will find self-locking stainless steel cable ties incredibly versatile. They adapt to a wide range of automation applications. Manufacturers offer them in various sizes and configurations to meet diverse needs. For instance, Panduit Pan-Steel® Self-Locking 304 Stainless Steel Cable Ties are available with tensile strengths ranging from 200 to 900 pounds. They come in a slim 0.18-inch width, with options for wider widths including 0.31″, 0.50″, and 0.63″ to accommodate more demanding loads.

These ties offer a range of tensile strength ratings, including 150 lb and 300 lb. The ZTY-SS05-150 stainless steel cable tie is a 5-inch long, non-coated roller ball type with a self-locking design and a 150lb tensile strength. It features an enclosed head for protection against dirt and grit. It also has rounded edges to prevent cable insulation damage. You can also request coated ties and stainless steel screw mounts for customized solutions. This wide array of options ensures you can find the perfect self-locking stainless steel cable ties for any specific requirement in your automation setup.

Solidifying Their Place: Self-Locking Stainless Steel Cable Ties in Automation’s Future

Seamless Integration with Advanced Automation Systems

You need reliable connections for advanced automation systems. Self-locking stainless steel cable ties provide the necessary stability. They ensure organized and secure cabling for sensors, actuators, and complex control units. This organization is vital for maintaining data integrity and system diagnostics in smart factories. Their robust nature supports long-term system performance. You can trust these ties to keep your critical infrastructure running smoothly. They simplify troubleshooting and upgrades. This makes your automation systems more adaptable and efficient.

Cost-Effectiveness Through Reduced Maintenance and Downtime

You will find significant cost savings by choosing self-locking stainless steel cable ties. Their exceptional durability directly translates into reduced maintenance and less downtime. Traditional cable management solutions often require frequent replacement. This leads to higher labor costs and material expenses.

| Metric | Stainless Steel Cable Ties | Plastic Cable Ties |

|---|---|---|

| Annual Replacements | 67% fewer | Higher |

| Inspection Frequency | 17% as often | Regular |

This table shows you can expect 67% fewer annual replacements with stainless steel ties. You also need to inspect them only 17% as often. This drastically cuts down on operational expenditures. Reduced maintenance means your systems stay online longer. This prevents costly interruptions. Remember, downtime in automation can cost hundreds of thousands of dollars per hour. Investing in these durable ties protects your bottom line.

Driving the Evolution of Resilient Cable Management

Self-locking stainless steel cable ties are driving the evolution of resilient cable management. They offer increased tensile strength and durability. They provide superior resistance to UV radiation, harsh chemicals, and extreme temperatures. Their self-locking mechanism ensures reliability. This design creates a secure, vibration-resistant connection. This is crucial for demanding applications where reliability is paramount. The stainless steel construction ensures longevity. This holds true even in harsh environments. It minimizes replacement costs and downtime.

These ties offer superior resistance to corrosion, high temperatures, and UV radiation. This makes them ideal for harsh industrial environments. They meet stringent safety regulations. These include fire retardancy, low smoke emission, and high strength. These features are crucial for critical infrastructure and equipment. You might notice a higher initial cost. However, their longevity and reduced maintenance requirements lead to a lower total cost of ownership over time. You are investing in a future-proof solution for your automation needs.

You will find self-locking stainless steel cable ties are not temporary fixes. They are fundamental for reliable and efficient industrial automation. Their superior durability, security, and adaptability make them indispensable. They meet the evolving demands of automated systems. These ties secure their place as a cornerstone of automation’s future. They offer long-term value and ensure robust cable management.

FAQ

What makes self-locking stainless steel cable ties better than plastic ones?

You gain superior durability and longevity. Stainless steel resists corrosion, extreme temperatures, and UV radiation. Plastic ties often become brittle and crack in harsh industrial settings.

How does the self-locking mechanism ensure security?

A rolling ball design inside the buckle creates an irreversible lock. When you tighten the tie, the ball wedges, preventing it from loosening. This provides a permanent, secure hold.

Can these cable ties withstand extreme industrial conditions?

Yes, they can. You will find them suitable for temperatures up to 1000°F and as low as -40°F. They also resist chemicals and mechanical stress, making them ideal for harsh environments.

Post time: Dec-19-2025