-

What Makes Stainless Steel Cable Ties Perfect in 2025?

You need solutions that endure the toughest conditions, and stainless steel cable ties deliver unmatched performance. Their durability ensures they hold strong under pressure. These ties resist corrosion, making them ideal for extreme environments. Versatility allows you to use them in countless...Read more -

Can Heavy Duty Stainless Steel Cable Ties Hold 350 Pounds

I have always been impressed by how heavy duty stainless steel cable ties can handle immense loads. These ties, crafted with high tensile strength, securely hold up to 350 pounds. Their ability to resist extreme temperatures and environmental factors ensures durability. When installed correctly,...Read more -

Why Stainless Steel Cable Ties Are a Must-Have in 2025

Stainless steel cable ties have become indispensable in 2025. Their importance is evident in key trends: The market is growing at a 6% CAGR through 2030, driven by electric vehicle adoption. Oil and gas investments exceeding $200 billion annually demand corrosion-resistant solutions for extreme...Read more -

Preventing Cable Failures: 3 Breakthroughs in Anti-Vibration Stainless Steel Ties

Cable failures in critical systems can lead to severe disruptions and financial losses. For instance: Between 2024 and 2035, approximately 3,600 failures could cost EUR 61.5 billion. Annual cable break rates range from 0.017% to 0.033% per kilometer. Stainless steel cable ties with anti-vibrat...Read more -

Quenching and tempering process of 316L stainless steel strip

Quenching and tempering are heat treatment processes used to improve the mechanical properties of materials, including stainless steel like 316L. These processes are often used to enhance hardness, strength, and toughness while maintaining corrosion resistance. Here’s how the quenching and ...Read more -

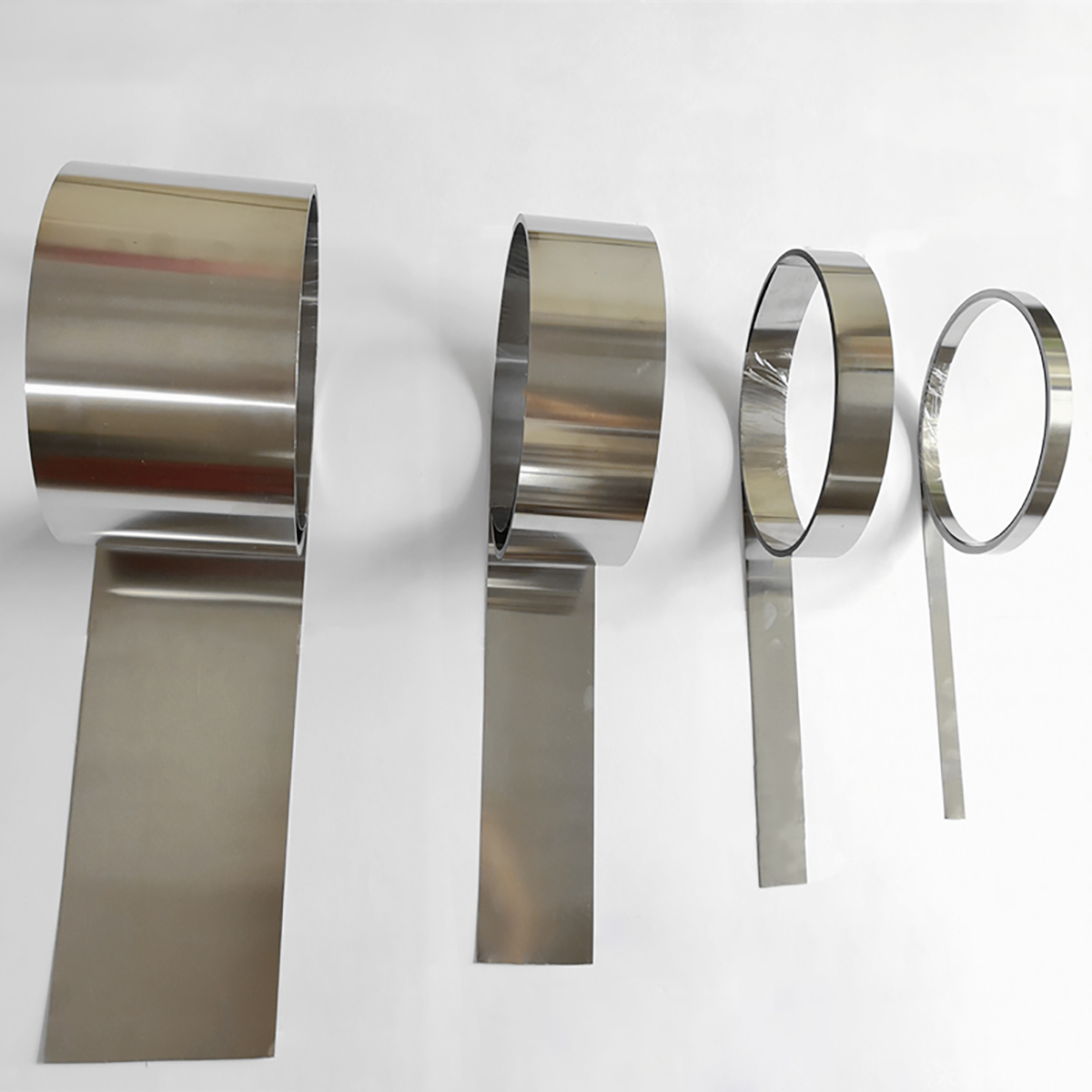

The concept, characteristics and production standards of 304 high-strength precision stainless steel strip

304 high-strength precision stainless steel strip is a high-precision product, and has very strict standards for the brightness, roughness, mechanical properties, hardness, precision tolerance and other indicators of the display, so it has become a leader in stainless steel strips. 1. The concept...Read more -

how stainless steel be used in kitchenware &what grades are most popular?

Stainless steel is widely used in kitchenware due to its various desirable properties. Here are some common applications of stainless steel in kitchenware: Cookware: Stainless steel is a popular material for pots, pans, and other cookware items. It offers excellent heat conductivity and distrib...Read more -

304 stainless steel plate selection method

When selecting a 304 stainless steel plate, there are several factors to consider to ensure it meets your specific requirements. Here is a step-by-step method for selecting a 304 stainless steel plate: 1.Determine the Application: Identify the purpose of the stainless steel plate. Consider factor...Read more -

What defects are prone to occur during surfacing welding of 304 stainless steel strip?

During the surfacing welding of 304 stainless steel strip, several defects may occur. Some common defects include: 1.Porosity: Porosity refers to the presence of small voids or gas pockets in the welded material. It can be caused by several factors such as inadequate shielding gas coverage, impr...Read more -

Where is China’s precision stainless steel belt mainly developed?

China’s precision stainless steel belt is mainly developed and manufactured in several key industrial regions in the country. Some of the prominent areas known for their production of precision stainless steel belt in China include: 1.Guangdong Province: Located in southern China, Guangdong...Read more -

what’s the difference between 410 &410S stainless steel

The main difference between 410 and 410S stainless steel lies in their carbon content and their intended applications. 410 stainless steel is a general-purpose stainless steel that contains a minimum of 11.5% chromium. It offers good corrosion resistance, high strength, and hardness. It is often ...Read more -

How much high temperature does the 201 stainless steel plate can withstand ?

First, we need to understand the chemical composition and physical properties of 201 stainless steel plates. 201 stainless steel plate is an alloy material containing 17% to 19% chromium, 4% to 6% nickel and 0.15% to 0.25% low carbon steel. This alloy material has excellent corrosion resistance ...Read more

Navigation

Contact Us

-

Address: #99 Mujin Road, Yinzhou District, Ningbo China.

Address: #99 Mujin Road, Yinzhou District, Ningbo China.

-

Phone/WeChat: 8615658728505

Phone/WeChat: 8615658728505

-

WhatsApp: 8618758320743

WhatsApp: 8618758320743

-

E-mail: info@wowstainless.com

E-mail: info@wowstainless.com

FOLLOW US

For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours

Inquiry Now

© Copyright - 2010-2023 : All Rights Reserved.