Self-locking stainless steel cable ties offer a robust and often ultimate solution for many industrial challenges. Their unique properties directly address the limitations of traditional fastening methods in demanding industrial environments. These ties provide unparalleled reliability and performance, making them indispensable for critical applications. Notably, 95% of industrial failures stem from fastener issues during installation or maintenance.

Key Takeaways

- Self-locking stainless steel cable ties are very strong. They last a long time in tough places. They fix many problems in factories.

- These ties work well in bad weather. They resist heat, chemicals, and water. This makes them good for many different jobs.

- Using these ties saves money. They do not break often. This means less fixing and less time when machines are not working.

Understanding the Power of Self-Locking Stainless Steel Cable Ties

What Defines Self-Locking Stainless Steel Cable Ties

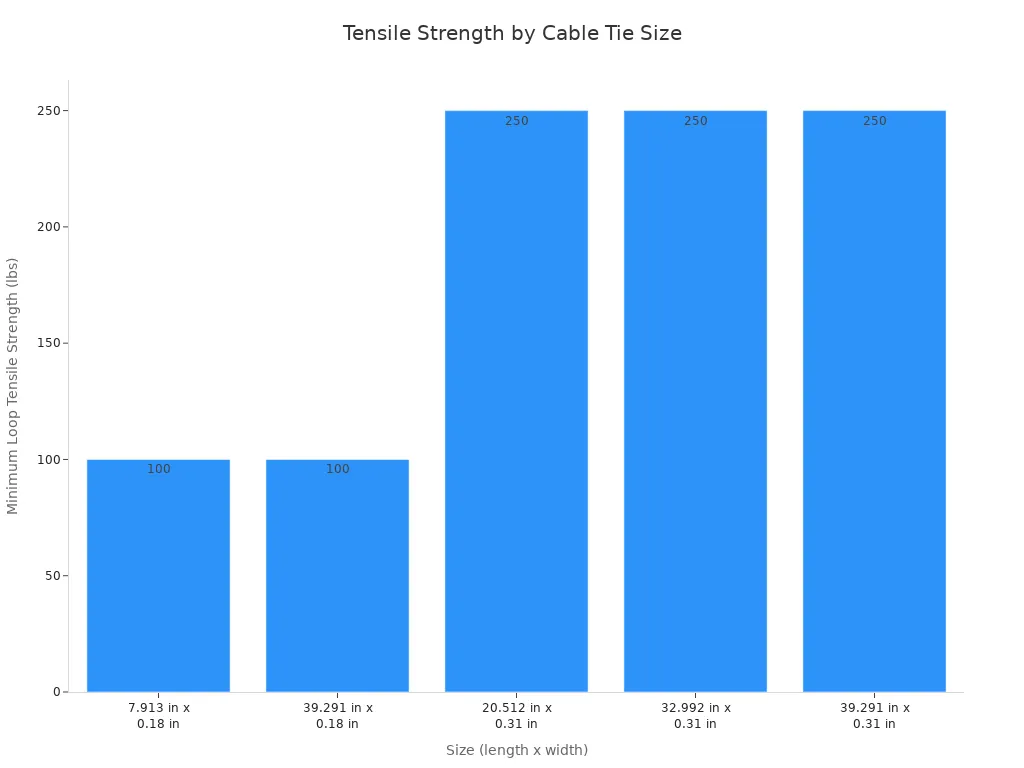

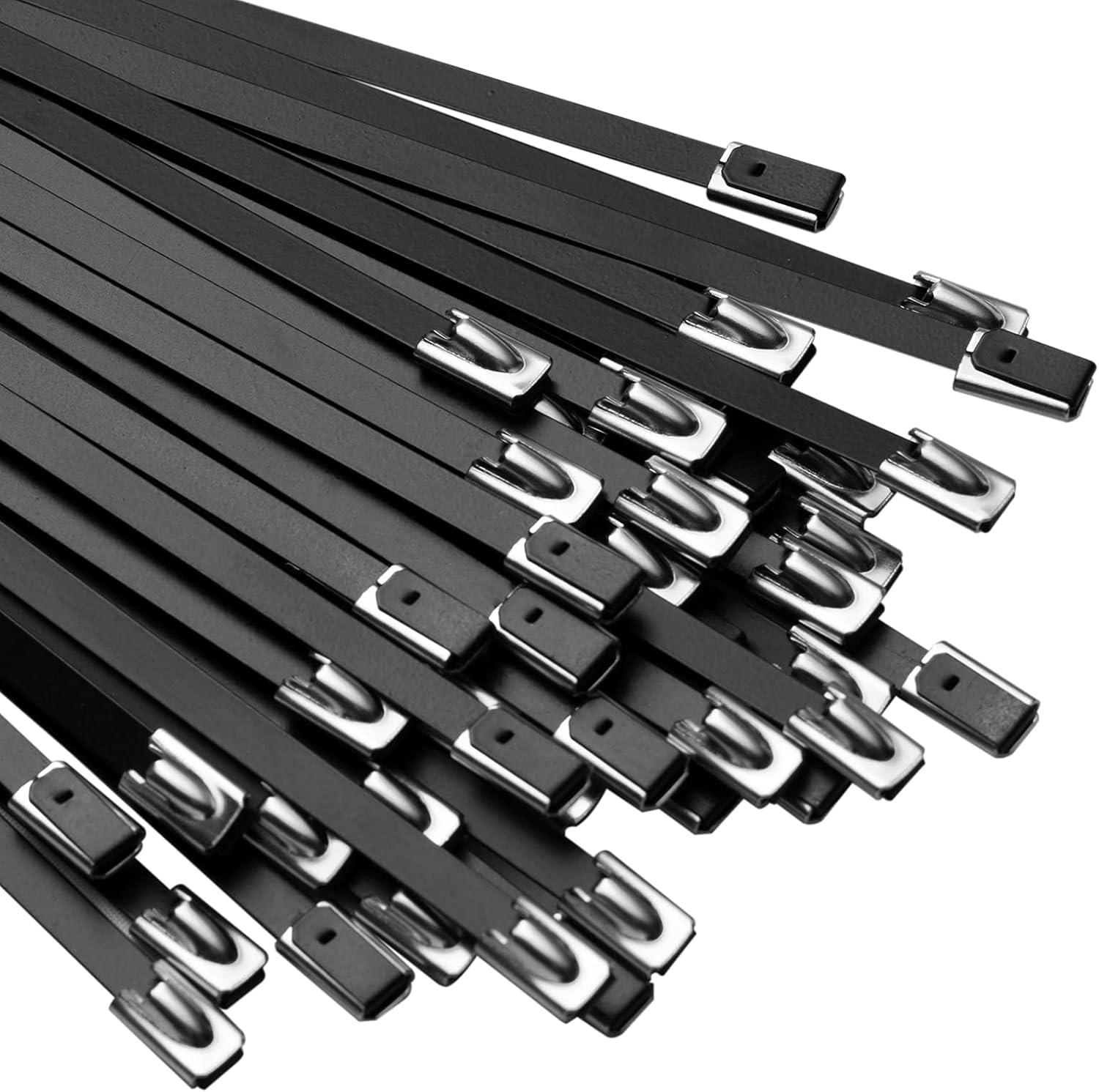

Self-locking stainless steel cable ties are robust fasteners engineered for demanding applications. Manufacturers produce them from AISI 304 or 316 stainless steel, ensuring a longer lifespan and superior mechanical resistance. These ties boast the highest tensile strength in the market. Cable tie tensile strength measures the maximum force a tie withstands before breaking. This strength is crucial for securely fastening components. For example, a 7.913 in x 0.18 in tie offers a 100 lbs minimum loop tensile strength, while a 20.512 in x 0.31 in tie provides 250 lbs. Minimum loop tensile strength indicates the load capacity the looped portion can withstand without deforming.

They typically feature either a Ball-Lock Type or Ladder Type locking mechanism.

Core Benefits for Industrial Problem Solving

These ties offer exceptional strength and durability, providing high tensile strengths from 200 to 900 pounds. They effectively support heavy industrial cable bundles. Their 304 stainless steel construction resists chemicals, salt spray, and high heat, making them ideal for harsh environments. The ball-locking mechanism prevents loosening under vibration or thermal cycling. This ensures a secure hold in petrochemical, marine, and utility-grade installations. Self-locking stainless steel cable ties also offer significant cost savings in strapping processes. They provide a strong pulling force, securing goods and preventing scattering. They withstand high-temperature radiation, ensuring a long fixed time and peace of mind.

Why Stainless Steel Excels in Harsh Industrial Settings

Stainless steel excels in harsh industrial settings due to its inherent properties. It withstands marine environments with saltwater and chemical environments with acids. Industrial settings often involve high temperatures, pressures, and corrosive substances. Stainless steel is a strong material; it resists deformation and mechanical stress. Its smooth, nonporous surface allows for easy cleaning, crucial for hygiene. Different grades of self-locking stainless steel cable ties offer varying corrosion resistance. 304 stainless steel resists mild corrosion, suitable for general use. 316 stainless steel, with molybdenum, provides superior resistance to salt spray and industrial chemicals. 316L offers even better protection in marine or chemical environments. Duplex stainless steel provides the highest strength and durability, ideal for offshore and petrochemical use.

Strategic Applications and Installation of Self-Locking Stainless Steel Cable Ties

Diverse Industrial Uses and Specific Advantages

Industries widely deploy self-locking stainless steel cable ties for securing hoses, cables, poles, and pipes. These ties perform reliably in indoor, outdoor, and underground applications. They withstand challenging environmental conditions such as corrosion, vibration, weathering, radiation, and temperature extremes. Many sectors benefit from their use, including chemical processing, civil infrastructure, food and beverage, metals and mining, oil and gas, power generation, and renewable energy. These ties offer exceptional tensile strength, superior corrosion resistance, and remarkable durability. They also resist UV radiation, moisture, high temperatures, and various chemicals like acids, alkalis, solvents, and oils.

In marine and offshore environments, these ties are indispensable. Stainless steel cable ties, especially AISI 304 or AISI 316 grades, resist saltwater and humid conditions on offshore rigs. This ensures long-term reliability. Their high tensile strength secures cables and pipes against mechanical stress and heavy vibrations, preventing accidents. They are flame retardant and withstand extreme temperatures, enhancing fire safety in electrical installations. WOW Stainless Steel Cable Ties are versatile, securing high-voltage cables and attaching identification tags in diverse offshore settings.

Selecting the Right Self-Locking Stainless Steel Cable Tie

Choosing the correct tie requires careful consideration of several factors. First, assess the application environment. Outdoor or corrosive settings demand UV-rated or stainless steel ties. High-heat applications require metal ties. Next, determine the bundle size; select appropriate length and width, allowing for future growth. Calculate the total weight of bundled cables to ensure the tie supports the load over time. Compliance needs are also critical; regulated industries often require products meeting UL, Mil-Spec, or specific industry certifications. Finally, ensure tool compatibility if using installation devices. Material grade, size, tensile strength, and resistance to temperature, chemicals, and UV are also vital selection criteria. For example, WOW Stainless Steel Cable Ties offer tensile strengths from 200 to 900 pounds and operate reliably from -60℃ to 550℃.

Best Practices for Secure and Lasting Installation

Proper installation ensures the longevity and effectiveness of stainless steel cable ties. Always select the right tie based on length, width, type, bundle size, and environmental exposure. Neatly bundle cables or objects, avoiding twisting or over-compression. Wrap the tie around the bundle and feed the tail through the self-locking head. Use a tensioning tool compatible with the tie’s width to pull it tight, ensuring consistent pressure. This prevents over-tightening and provides a secure hold. Trim any excess tie material with a sharp cutting tool to ensure a clean, safe finish without sharp edges. Finally, inspect the tie to verify it is secure, the bundle is firm, and the locking mechanism is fully engaged. Protective gloves are recommended during installation due to potentially sharp edges.

Real-World Solutions: How Self-Locking Stainless Steel Cable Ties Tackle Industrial Challenges

Preventing Cable Management Failures and Enhancing Safety

Industrial environments face numerous challenges in cable management. These issues often lead to significant failures and safety hazards. Mechanical damage, for instance, frequently occurs from pinching, compression, improper routing, and excessive bending. These actions cause insulation failure, short circuits, and signal loss. Electrical factors like overloading, voltage surges, and electromagnetic interference also disrupt operations and damage equipment. Environmental factors such as moisture and extreme temperatures lead to corrosion and make cables brittle. Poor installation of connectors and incorrect handling, including kinking or twisting cables, further contribute to failures. Rodents chewing on cables cause short circuits and fires. Chemical exposure erodes insulation and corrodes connectors.

Poor cable management directly impacts industrial safety records. Messy cables create trip hazards, increasing workplace injury risks. Loose cables on the floor cause falls, leading to workers’ compensation claims. Unsecured overhead cables can fall, injuring personnel or damaging equipment. Regulatory non-compliance also results from poor cable practices, leading to fines and increased insurance premiums. Cables running across power connections create shock hazards. Damaged cables hidden in tangled masses cause equipment failures or electrical fires. The National Fire Protection Association (NFPA) identifies faulty electrical connections as a leading cause of data center fires. In healthcare, poorly organized cables pose risks to staff moving quickly. Loose cables obstruct emergency exits. Cable clutter also creates areas for dust, bacteria, and pathogens to accumulate, hindering efforts to maintain sterile environments. The CDC reports that hospital-acquired infections (HAIs) affect nearly 1.7 million patients annually. Reducing clutter through proper cable management lowers contamination risks. Self-locking stainless steel cable ties provide a robust solution, securing cables effectively and mitigating these risks.

Reducing Maintenance and Downtime Costs

Industrial operations constantly seek ways to reduce maintenance and downtime costs. Self-locking stainless steel cable ties offer a proven method for achieving these savings. A case study from BAND-IT highlights significant cost reductions in a harsh refinery environment. The refinery previously used plastic cable ties, which had a lifespan of only six months. Switching to 316 Stainless Steel BAND-IT ties extended the lifespan to five years, representing a tenfold improvement. This extended lifespan directly reduces the frequency of replacements. It minimizes associated labor costs and operational downtime. The ease of installation of the BAND-IT ties, using a ratchet-operated Bantam strapping tool, further contributes to reduced downtime during initial setup and subsequent maintenance. This demonstrates how a simple change in fastening technology yields substantial economic benefits.

Ensuring Compliance and Longevity in Extreme Environments

Compliance with industry standards and ensuring longevity are critical in extreme industrial environments. Self-locking stainless steel cable ties excel in these demanding conditions. Manufacturers produce them from corrosion-resistant stainless steel, typically grade 304 or 316. This material delivers excellent strength, durability, and resistance to chemicals, UV, extreme temperatures, and vibration. Grade 316 is recommended for marine or chemical exposure. It ensures a long service life even in chemically aggressive or salty environments. These ties specifically withstand exposure to moisture, chemicals, saltwater, and other corrosive environments. They prevent rust, degradation, and failure common with standard ties. Roller Ball Cable Ties, made from corrosion-resistant stainless steel, offer excellent long-term performance in hostile environments. This includes outdoor, marine, and chemically aggressive settings. Premium-grade stainless steel provides exceptional tensile strength, corrosion resistance, and durability under high-temperature conditions. It resists corrosion, oxidation, and chemical attack, extending service life and reducing maintenance and replacement costs.

Stainless steel cable ties stand up to corrosive atmospheres, aggressive chemicals, and salt-spray. They resist chemical corrosion and environmental degradation. This makes them ideal for challenging environments like saltwater and chemical exposure. They offer significant long-term cost savings due to their extended lifespan. Traditional nylon ties might last one to two years outdoors. Stainless steel ties, however, can endure for decades in harsh conditions such as chemical plants or saltwater environments. This reduces replacement costs and maintenance efforts. Premium grade materials, specifically 316 Stainless Steel, are ideal for environments with high salt, chlorine, or harsh chemicals. They ensure long-term reliability in aggressive settings. 304 Stainless Steel suits less aggressive environments, offering resistance to moisture and oxidation. Self-locking stainless steel cable ties typically last between 10 to 30 years in demanding industrial applications. They exceed the 10-year mark even in harsh industrial environments. They maintain tensile strength and flexibility where plastic alternatives fail within months. Industrial facilities report that these heavy-duty ties eliminate the need for frequent replacements, even in challenging environments like chemical processing plants.

These robust fasteners offer a powerful, versatile, and often ultimate solution for industrial challenges. Their durability, reliability, and resistance to harsh conditions effectively mitigate numerous industrial headaches. Investing in these ties ensures long-term performance, enhanced safety, and significant cost savings in industrial operations.

FAQ

What makes self-locking stainless steel cable ties superior to plastic ties?

Stainless steel ties offer unmatched strength, durability, and resistance to extreme temperatures, corrosion, and UV radiation. They last decades longer than plastic alternatives in harsh industrial settings.

Are WOW Stainless Steel Cable Ties reusable?

Some designs of WOW Stainless Steel Cable Ties offer reusability. This feature contributes to waste reduction and provides flexibility for certain applications.

What environments are ideal for WOW Stainless Steel Cable Ties?

These ties excel in marine, chemical, automotive, and high-temperature environments. They resist saltwater, acids, vibrations, and extreme heat, ensuring reliable performance.

See Also

Essential Industrial Air Fryers: Top 5 Picks for High-Volume Kitchens

Dishwasher Safety for Air Fryer Baskets: Your Complete Guide Revealed

Perfect Air Fryer Sausage Patties: Simple Recipes and Expert Cooking Tips

Best Air Fryer Options: Beyond BrandsMart’s Selection for 2024

Achieve State Fair Corn Dog Perfection: The Ultimate Air Fryer Method

Post time: Dec-24-2025