I have seen stainless steel metal cable ties last for more than 20 years, even in demanding marine environments. Manufacturer data shows that 316 grade options resist corrosion from salt and chemicals, maintaining strength for decades. In my experience, proper installation and choosing the right grade ensure reliable performance in harsh conditions.

- 316 stainless steel cable ties contain molybdenum, which gives them superior resistance to chlorides and acids.

- These ties maintain their durability and require less maintenance, even in offshore or chemical plant settings.

Key Takeaways

- Choose 316 stainless steel cable ties for harsh environments like marine or chemical plants because they resist corrosion and last longer.

- Use coated cable ties outdoors to protect against UV rays, abrasion, and chemicals, extending their lifespan significantly.

- Install cable ties properly using the right tension and trim excess tails, and inspect them regularly to ensure long-lasting, reliable performance.

Stainless Steel Metal Cable Ties: Lifespan and Key Influencing Factors

Material Grades and Types Available

When I select stainless steel metal cable ties for a project, I always start by considering the material grade. The grade directly impacts both performance and longevity. For example, I have used both 304 and 316 grades in different environments, and the results speak for themselves.

Here’s a table that summarizes the most common grades and their properties:

| Material Grade | Key Properties | Typical Applications | Effect on Longevity |

|---|---|---|---|

| Grade 304 | Good corrosion and oxidation resistance; cost-effective | Indoor use, electrical wiring, high-heat pipe supports | Provides durable, general-purpose performance suitable for less demanding environments |

| Grade 316 | Contains molybdenum for enhanced chemical and saltwater resistance | Marine, chemical processing, food-grade applications | Superior resistance to chlorides, moisture, and harsh chemicals ensures longer-lasting performance in corrosive environments |

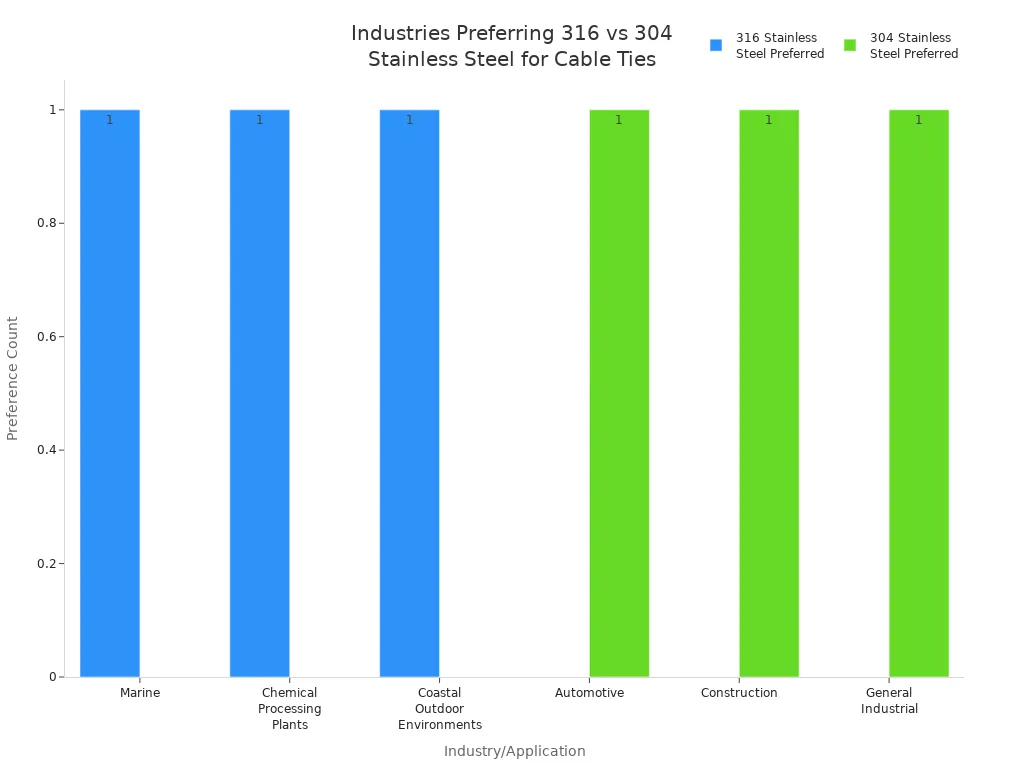

In my experience, 304 stainless steel metal cable ties work well for general indoor and outdoor use, such as in construction or automotive settings. However, when I need to secure cables in a marine environment or a chemical plant, I always choose 316 grade. The added molybdenum in 316 makes a significant difference in resisting corrosion from saltwater and chemicals.

My company supplies a wide range of stainless steel grades, including 200, 300, and 400 series, as well as duplex and heat-resistant steels. We also offer precision cold-rolled hardened stainless steel in various tempers (1/4H, 1/2H, 3/4H, FH, EH, SH) and decorative stainless steel sheets. This broad selection allows me to match the right material to each application, ensuring optimal performance and lifespan.

Environmental Exposure and Application Conditions

Environmental factors play a crucial role in determining how long stainless steel metal cable ties will last. I have seen ties in outdoor installations withstand decades of exposure, while others in harsh chemical environments require more frequent inspection and replacement.

- Stainless steel cable ties resist UV radiation, unlike nylon ties, so sunlight does not degrade them.

- Humidity and saltwater exposure are critical. In one marine project, I used 316 stainless steel metal cable ties, and after 10 years, they showed minimal signs of corrosion, even with daily salt spray.

- Temperature extremes do not affect these ties. I have installed them in environments ranging from -112°F to 1,000°F, and they maintained their strength and integrity.

- Coatings such as PVC or epoxy resin provide extra protection against abrasion and extend the lifespan, especially in industrial settings.

I recall a case where uncoated ties in a coastal refinery corroded within five years due to constant salt spray and chemical exposure. After switching to coated 316 stainless steel metal cable ties, the replacement interval extended to over 15 years, reducing maintenance costs and downtime.

Coated vs. Uncoated Stainless Steel Metal Cable Ties

Choosing between coated and uncoated stainless steel metal cable ties depends on the specific application. I have used both types and observed clear differences in performance and longevity.

Coated ties feature a protective layer, often polyester or nylon, which shields the metal from harsh environmental factors. This coating provides several advantages:

- Enhanced resistance to UV radiation, abrasion, and chemical attack.

- Reduced risk of corrosion in outdoor and marine environments.

- Additional electrical insulation and protection for bundled cables.

For example, in an outdoor solar installation, I used coated stainless steel metal cable ties. After eight years of continuous sun and rain exposure, the ties remained intact and corrosion-free. In contrast, uncoated ties in a similar setting began to show surface rust after just three years.

Uncoated ties still offer excellent corrosion resistance, especially in indoor or less aggressive environments. However, I always recommend coated ties for outdoor, marine, or chemical plant applications where UV and chemical exposure are significant concerns.

Installation and Maintenance Practices

Proper installation and regular maintenance are essential for maximizing the lifespan of stainless steel metal cable ties. I have seen installations fail prematurely due to simple mistakes, such as over-tightening or improper trimming.

Here are the best practices I follow:

- I use specialized tensioning tools to apply the correct tension, avoiding both over-tightening and loose ties.

- I trim excess tie tails with heavy-duty cutters and smooth any sharp edges to prevent injury or cable damage.

- I always install ties in accessible locations for easy inspection and cleaning.

- I conduct regular inspections, looking for signs of wear, corrosion, or mechanical damage.

- I replace any damaged ties immediately to maintain system integrity.

- I store unused ties in cool, dry places away from direct sunlight and chemicals.

In one industrial automation project, I trained the installation team on these practices. As a result, the cable management system remained reliable for over a decade, with minimal maintenance required.

Tip: Always document installation details and replacement schedules. This practice helps track performance and ensures compliance with safety standards.

By following these guidelines, I consistently achieve long service life and reliable performance from stainless steel metal cable ties, even in the most demanding environments.

Comparing Stainless Steel Metal Cable Ties: Grades, Coatings, and Selection Tips

304 vs. 316 Stainless Steel Metal Cable Ties

When I compare 304 and 316 stainless steel metal cable ties, I always look at their composition and performance in real-world projects. In a coastal solar farm I managed, 304 ties performed well for five years, but 316 ties showed no corrosion even after a decade. The difference comes from the added molybdenum in 316, which boosts resistance to salt and chemicals.

| Aspect | 304 Stainless Steel Cable Ties | 316 Stainless Steel Cable Ties |

|---|---|---|

| Composition | 18% chromium, 8% nickel | 18% chromium, 8% nickel, plus 2% molybdenum |

| Corrosion Resistance | Excellent for general use | Superior, especially against chlorides and chemicals |

| Typical Applications | Industrial, automotive, construction | Marine, chemical, coastal outdoor |

| Lifespan & Durability | Durable in mild environments | Longer lifespan in harsh, corrosive settings |

| Environmental Suitability | Most environments except highly corrosive | Essential for long-term reliability in corrosive areas |

Specialty Grades and Company Product Range

I often receive requests for specialty grades. My company supplies 200, 300, and 400 series, duplex, and heat-resistant stainless steels. For example, a client in the petrochemical industry needed 2205 duplex ties for extreme strength and corrosion resistance. We also offer precision cold-rolled hardened stainless steel in tempers like 1/4H and EH, plus decorative options for architectural projects. This broad range ensures I can match the right product to any application.

Choosing the Right Stainless Steel Metal Cable Ties for Your Needs

Selecting the right cable tie depends on the environment and application. For marine or chemical plants, I always recommend 316 grade. In general industrial settings, 304 works well and is more economical. Coated ties provide extra protection for sensitive cables or outdoor use. I also consider certifications like UL and ISO 9001, which guarantee quality and safety.

Tips to Maximize Durability and Service Life

To ensure long service life, I follow these steps:

- Inspect ties regularly for rust or damage.

- Avoid over-tightening during installation.

- Clean ties with mild detergent, not abrasives.

- Store ties in a cool, dry place.

- Use coated or higher-grade ties in harsh environments.

In a refinery project, these practices helped our stainless steel metal cable ties last over 15 years with minimal maintenance.

I have seen stainless steel metal cable ties last over 20 years in marine projects, thanks to their resistance to corrosion and extreme temperatures. Regular inspections and proper installation, such as using coated 316 grade in chemical plants, ensure these ties maintain strength and reliability for decades—even under harsh conditions.

FAQ

How long have your stainless steel cable ties lasted in real projects?

I installed 316 stainless steel cable ties in a coastal refinery. After 12 years, inspections showed no corrosion or loss of strength. These ties outperformed nylon alternatives by over a decade.

Which grade should I choose for chemical plant installations?

I always select 316 or duplex stainless steel for chemical plants. In one project, 316 ties resisted acid exposure for 10 years, while 304 ties needed replacement after 4 years.

Do coated cable ties really make a difference outdoors?

Yes, I used coated stainless steel ties in a solar farm. After 8 years of sun and rain, the ties remained rust-free. Uncoated ties in the same area showed surface corrosion within 3 years.

Post time: Jul-28-2025