Self-locking stainless steel cable ties are essential for the durability and reliability of your renewable energy projects. These ties provide critical wiring protection in harsh solar and wind environments. You will find their role fundamental to the longevity and efficiency of these vital installations.

Key Takeaways

- Self-locking stainless steel cable ties are very strong. They last a long time in tough outdoor places like solar farms and wind turbines.

- These special ties protect wires better than plastic ones. They do not break from sun, heat, cold, or strong winds.

- Using these ties makes solar and wind power systems work better and last longer. This helps save money and makes clean energy more reliable.

Why Traditional Cable Management Fails in Renewable Energy Environments

Unique Challenges for Solar and Wind Installations

You install solar panels and wind turbines in some of the planet’s most demanding locations. These environments present unique challenges for cable management. Consider the constant assault from extreme UV exposure. Continuous sunlight breaks down standard plastic cable ties, making them brittle. You also face significant temperature variations, from scorching heat to freezing cold. These changes cause materials to expand and contract, stressing your cable ties. Moisture and humidity, from rain and snow, further weaken many plastics. High winds and constant mechanical stress from turbine movement or thermal expansion also cause ties to loosen or snap. Furthermore, chemical exposure from agricultural runoff or coastal salt air can corrode or weaken standard cable management solutions.

Limitations of Plastic Cable Ties

Traditional plastic cable ties often fail in these harsh conditions. You might use basic nylon ties, but they degrade quickly under UV rays. They become brittle and snap, especially in outdoor applications. This happens because UV radiation breaks down molecular bonds in plastics. Another common issue is creep. Plastic ties can slowly stretch and loosen under sustained load, failing to hold cables securely over time. The locking mechanism itself can also fail. If the teeth deform or lose engagement, the tie loosens, regardless of its tensile strength. Finally, aging-related failures are common. Elevated temperatures from electrical currents or solar radiation cause many plastics to soften and deform. This compromises their load retention and leads to premature failure. You need solutions that withstand these relentless environmental attacks.

The Unmatched Advantages of Self-Locking Stainless Steel Cable Ties

Superior Material Properties for Harsh Conditions

You need materials that stand up to the toughest environments. Self-locking stainless steel cable ties offer superior material properties. They resist corrosion, extreme temperatures, and UV radiation. This makes them ideal for solar and wind installations. Unlike plastic, stainless steel does not degrade under constant sunlight. It maintains its integrity in both scorching heat and freezing cold. You will find these ties perform reliably where other materials fail.

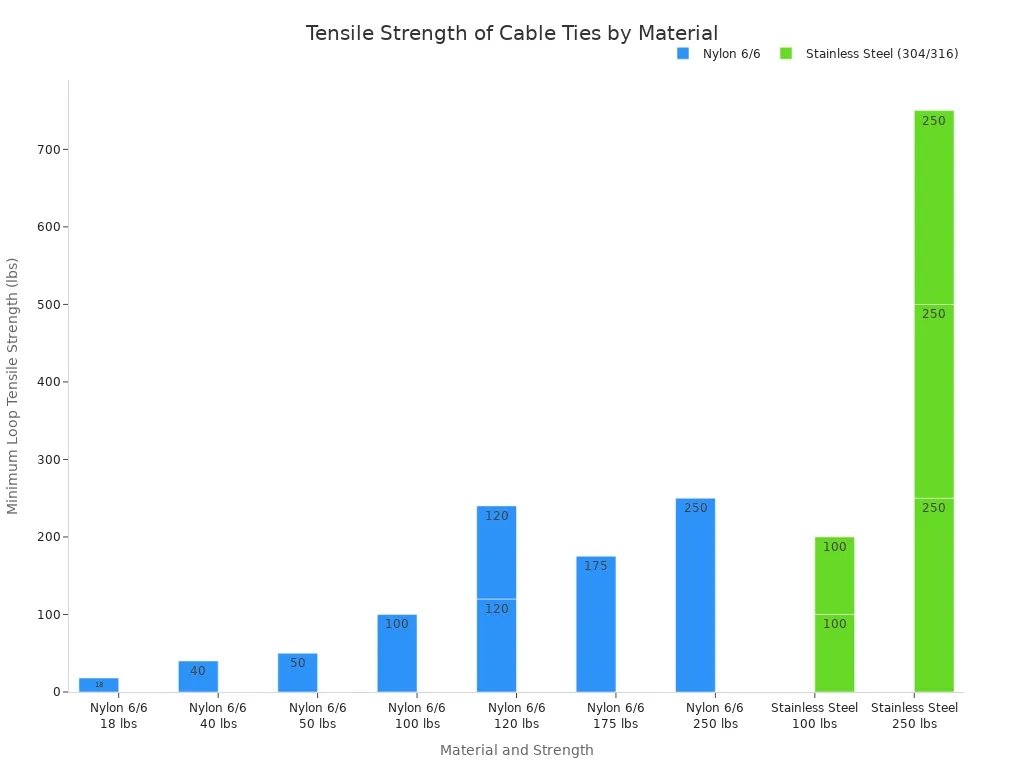

Consider the significant difference in strength.

| Material | Size (length x width) | Minimum Loop Tensile Strength |

|---|---|---|

| Nylon 6/6 | 3.780 in x 0.100 in | 18 lbs |

| Nylon 6/6 | 5.910 in x 0.140 in | 40 lbs |

| Nylon 6/6 | 6.300 in x 0.180 in | 50 lbs |

| Nylon 6/6 | 14.960 in x 0.250 in | 100 lbs |

| Nylon 6/6 | 8.580 in x 0.300 in | 120 lbs |

| Nylon 6/6 | 14.960 in x 0.300 in | 120 lbs |

| Nylon 6/6 | 24.020 in x 0.350 in | 175 lbs |

| Nylon 6/6 | 9.060 in x 0.500 in | 250 lbs |

| Stainless Steel (304/316) | 7.913 in x 0.18 in | 100 lbs |

| Stainless Steel (304/316) | 39.291 in x 0.18 in | 100 lbs |

| Stainless Steel (304/316) | 20.512 in x 0.31 in | 250 lbs |

| Stainless Steel (304/316) | 32.992 in x 0.31 in | 250 lbs |

| Stainless Steel (304/316) | 39.291 in x 0.31 in | 250 lbs |

You can see the strength comparison clearly.

Heavy-duty nylon ties offer 120–175 lb tensile strength. This suits serious loads. Extra heavy-duty and stainless steel ties provide 250–300+ lb tensile strength. You reserve these for critical and punishing conditions. These include extreme temperatures, chemical exposure, or outdoor infrastructure.

Enhanced Security with Self-Locking Mechanisms

Self-locking stainless steel cable ties provide superior security. Their design prevents slippage and loosening.

- The cable tie has a flexible band. It features tiny teeth or ridges on one side.

- You loop the tie around items. Then you insert the pointed end into the locking mechanism.

- As you pull the tie tight, a ratchet mechanism engages. The teeth inside the mechanism grip the ridges on the tie’s band. This prevents loosening or sliding back.

- This ratchet mechanism locks the tie securely. It maintains a firm grip on the bundled items. Once locked, you cannot easily undo it without cutting. This ensures a tamper-resistant and reliable fastening solution.

These ties incorporate a built-in locking mechanism. This mechanism is typically in the tie head. It grips the tail once you insert it. These mechanisms can be:

- A plastic or metal ratchet-style tooth. This allows one-way movement.

- A ball bearing system. This is common in stainless steel ties. It wedges the tail in place.

- A roller-locking device. Manufacturers design this for higher tensile loads.

Once the tail passes through the head, it cannot slide back. This results in a tight, reliable grip. It resists loosening under stress. Stainless steel cable ties feature a self-locking mechanism. This ensures a secure and tight fastening. Once tightened, the tie locks in place. It prevents loosening or slippage over time. This mechanism, combined with superior strength, durability, and resistance to environmental conditions, contributes to their secure and long-lasting hold.

Durability and Longevity for Reduced Maintenance

You want solutions that last. Stainless steel cable ties offer exceptional durability and longevity. This significantly reduces your maintenance needs.

| Type of Cable Tie | Expected Lifespan (Years) | Conditions Impacting Lifespan |

|---|---|---|

| Stainless Steel | Decades | Unaffected by sunlight, rain, extreme temperatures, wild temperature swings, or salty air. |

| Stainless Steel | 5 or more | Stands up to high heat, saltwater spray, industrial chemicals. |

| UV-Resistant Nylon | 5 to 7 (2 to 5 in harsh) | High altitude, coastal salt, desert sun can shorten life. |

| Nylon | 1 to 2 | Non-UV resistant ties wear out quickly. |

Stainless steel ties can last for decades. They remain unaffected by sunlight, rain, extreme temperatures, or salty air. In outdoor industrial settings, they regularly exceed 10 years. This happens even in harsh environments. This extended lifespan translates directly into cost savings. Stainless steel cable ties can last 15 to 20 years in harsh industrial environments. This is significantly longer than nylon or galvanized steel ties. They require 87% fewer replacements. This leads to substantial savings in maintenance costs. Their durability and low maintenance requirements, including corrosion resistance, make them more cost-effective over time. They reduce the frequency of replacements and repairs. The longevity of high-grade stainless steel ties leads to cost savings. You benefit from reduced replacement frequency and reliable performance over time.

Ensuring Safety and Reliability in Operations

Safety and reliability are paramount in renewable energy. Self-locking stainless steel cable ties contribute significantly to both. They are non-combustible. This makes them a safe choice where fire safety is a concern. These cable ties exhibit high resistance to high temperatures and flame. You use them in environments with a risk of fire. These include shipbuilding, offshore, petrochemical plants, and oil rigs. They serve as a flame safety measure in electrical installations. They secure metal ID plates. These plates must preserve information in case of fire. Stainless steel cable ties resist extreme heat and fire. This makes them suitable for industrial and hazardous locations. They remain unaffected by fire conditions. You can trust them to maintain cable integrity. This ensures continuous operation and protects your investments.

Specific Applications of Self-Locking Stainless Steel Cable Ties in Solar Installations

Securing PV Module Wiring and Junction Boxes

You must properly support wiring along PV modules and racking equipment. This involves choosing appropriate components. Stainless steel wire clips are available in various forms. They fasten to module frames or mounting rails. They clamp single or multiple USE-2, PV wire, or TC-ER cables. When installing, use the correct tension. Avoid over-tightening to prevent cable damage. Use a tensioning tool for precise tightening. Do not overload bundles. Regularly inspect and replace worn ties. Choose stable structures like panel frames for attachment points. Avoid over-tightening cable ties; this can cut insulation. Do not leave cables loose or unprotected from sunlight or wind.

Managing Inverter Cabling and Grounding Wires

Inverter cabling requires robust protection. Self-locking stainless steel cable ties offer exceptional heat resistance. They withstand temperatures that would melt plastic ties. This makes them useful in high-temperature solar farm applications. Grade 316 stainless steel resists rust and degradation from saltwater. This ensures long-term performance in coastal areas. Weather-resistant coated ties combine strength with insulation. This protects against extreme temperatures, moisture, and mechanical stress. The coating prevents sharp edges from damaging delicate cables. These ties resist chemical exposure and environmental contaminants. They withstand high winds and mechanical strain.

Organizing Cables on Racking Systems and Trackers

You need reliable solutions for organizing cables on racking systems and trackers. Stainless steel ties perform reliably in outdoor environments. They protect against environmental exposure. Their high tensile strength secures cables under stress. They offer long-lasting performance in extreme temperatures. The self-locking mechanism ensures a firm hold. This prevents slipping and resists vibration. These ties are fireproof and resist chemicals, salt, and weather. They will not degrade or become brittle. This ensures long-term reliability.

Specific Applications of Self-Locking Stainless Steel Cable Ties in Wind Installations

Cable Management Within Nacelles and Towers

You face significant challenges managing cables inside wind turbine nacelles and towers. Cable slack and slippage are primary issues. Excess cable length or uncontrolled movement can lead to problems. Slack cables rubbing against structures cause mechanical abrasion. This degrades insulation and creates electrical faults or short circuits. Slippage also stresses cable terminations and connectors, causing loosening and signal loss. Severe slippage can even entangle cables. These issues increase your maintenance burden. Dynamic operating conditions, like constant rotation and vibration, cause cables to shift. Thermal expansion and contraction also create cumulative slack. You need robust solutions to prevent these failures.

Securing Sensor and Control Wiring

You must secure sensor and control wiring against constant vibration. Self-locking stainless steel cable ties are ideal for this task. They are made from corrosion-resistant alloys like 304 or 316 grade steel. These ties endure mechanical stress and chemical exposure. Unlike nylon, they maintain tensile strength across vast temperature ranges. They resist UV radiation, extreme cold, and physical impact without cracking. Their self-locking ball bearing or ladder-type mechanisms create a firm grip. This grip does not loosen over time, providing a permanent hold even in high-vibration environments. These ties offer high tensile strength, holding heavy cables without slipping. They ensure your sensors and signaling systems remain fixed and operational.

Protecting Cables from Vibration and Movement

You must protect cables from constant vibration and movement in wind turbines. Wind loads causes blades to flex and vibrate. Temperature fluctuations lead to expansion and contraction, promoting crack formation. Ice accumulation adds unbalanced weight, causing vibration and edge damage. Storm events generate high-magnitude forces. These forces can exceed blade design tolerances. These conditions cause microcracking, resin breakdown, delamination, and surface erosion in turbine components. Self-locking stainless steel cable ties help mitigate these risks. They secure cables firmly, preventing them from contributing to or suffering damage from these dynamic forces. This ensures the long-term integrity of your electrical systems.

Driving Renewable Energy Adoption with Self-Locking Stainless Steel Cable Ties

Improving System Reliability and Uptime

You want your renewable energy systems to run without interruption. Durable cable management solutions significantly improve system reliability and uptime. AI-driven cable management, which uses predictive analytics and real-time data from IoT sensors, changes how utilities manage cable networks. This approach shifts from fixing problems after they happen to preventing them before they occur. This greatly increases grid reliability. It is crucial for integrating solar and wind energy without frequent disruptions. By preventing outages, you reduce the need for carbon-intensive backup generators. You also minimize emissions from emergency repairs. This helps meet sustainability goals and speeds up the adoption of clean energy technologies. It also ensures a more consistent power supply for customers. This meets expectations for high service quality.

Improved cable management, especially with digital and monitoring technologies, allows you to move from a ‘fail and fix’ approach to ‘predict and prevent’ maintenance. This method greatly boosts efficiency and safety. It leads to better uptime and reliability by cutting down on costly outages. It also makes your equipment last longer. This reduces environmental and financial costs from frequent replacements. Cable failures can stop power supply, weaken system strength, and cause big financial losses and safety risks. This is especially true in remote or offshore areas where repairs are hard and expensive. Therefore, finding problems early and using smart maintenance plans are vital for safe, efficient, and lasting operations.

Lowering Long-Term Operational Costs

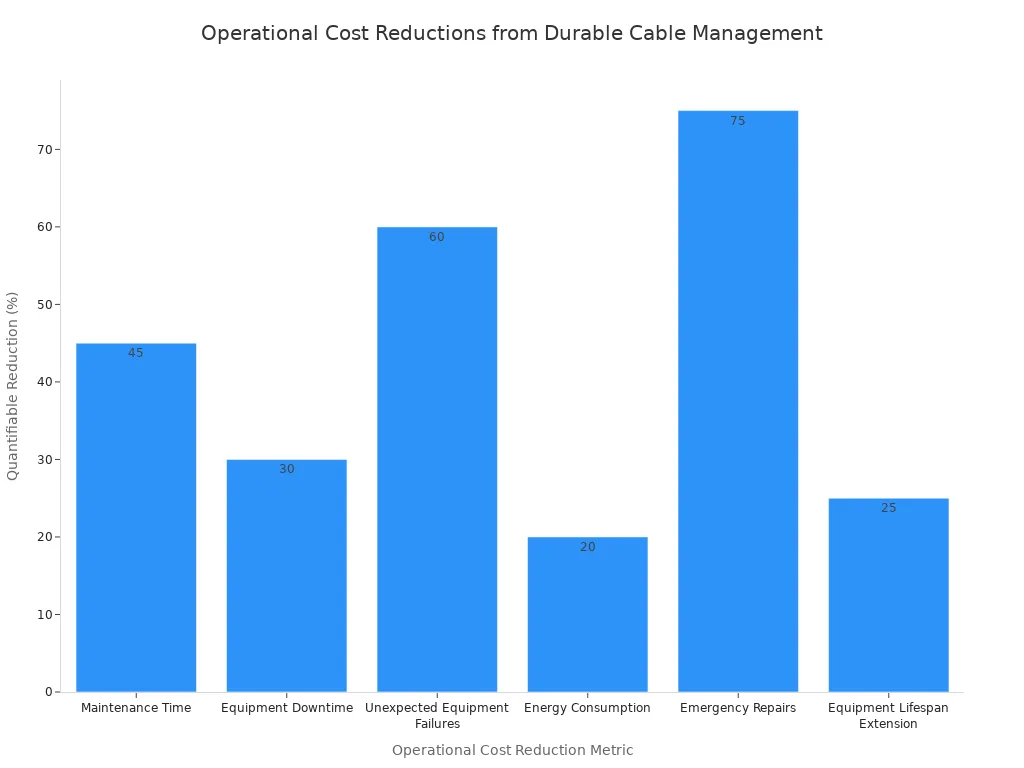

You can achieve significant savings over the long term by investing in durable cable management. These solutions drastically reduce operational costs.

| Operational Cost Reduction Metric | Quantifiable Reduction |

|---|---|

| Maintenance Time | Up to 45% |

| Equipment Downtime | 30% |

| Unexpected Equipment Failures | 60% fewer |

| Energy Consumption | 15-25% |

| Emergency Repairs | 75% |

| Equipment Lifespan Extension | 20-30% |

You can see the impact of durable cable management solutions on operational costs.

Strategic investments in cable management often pay for themselves within 18-24 months. This happens through lower labor costs and more reliable equipment. You save money by avoiding frequent repairs and replacements.

Meeting Stringent Industry Standards and Certifications

You must meet strict industry standards and certifications for cable management components in renewable energy. These standards ensure safety, quality, and performance.

- NFPA 70 (National Electrical Code): This sets basic rules for how well cables resist fire and how much smoke they produce.

- NFPA 262: This standard describes the test method for checking how high flames spread on electrical cables in trays. It helps determine ratings like CMR (Communications Riser) or CMP (Communications Plenum).

- NFPA 72 (National Fire Alarm and Signaling Code): This sets rules for fire alarm system wiring. It makes sure the system works during a fire, with ratings like FPLR (Fire Power Limited Riser), FPLP (Fire Power Limited Plenum), and CI (Circuit Integrity).

Many other certifications also apply to your PV cables and systems:

- ISO 14001: This is an environmental management system. It shows your commitment to environmental responsibility and sustainability.

- ISO 9001: This quality management standard ensures consistent product quality, customer satisfaction, and continuous improvement.

- IATF 16949: This quality management standard is for the automotive sector. It is important for PV cable makers who supply products for car solar integration. It focuses on consistency, reliability, and ongoing improvement.

- TÜV Certifications: These are product-specific certifications for PV cables. They ensure quality, safety, and performance under specific stresses and environmental conditions.

- TÜV 2PfG 2642/01.22: This is a special standard for single-conductor DC cables in PV systems. It checks resistance to sunlight, temperature changes, moisture, and mechanical stress.

- TÜV 2PfG 2693: This ensures PV cables perform safely in solar energy systems. It covers electrical properties, physical traits, and overall strength.

- TÜV 2962 Floating Cable Certificate.

- IEC 62893: This is an international standard for PV cables. It ensures safety, reliability, and performance in solar power systems. It covers electrical, mechanical, and environmental properties.

- UL Standard TC-ER: This Underwriters Laboratories standard is for Tray Cables – Exposed Run. You use it in industrial, commercial, and home wiring, including PV systems. It ensures electrical safety, mechanical strength, and environmental durability.

- EN 50620: This European standard covers the performance and safety of PV cables in solar energy systems. It ensures quality, durability, and safety in different environmental conditions.

- UL 1072 Certificate.

Enabling Robust and Resilient Renewable Energy Infrastructure

You build a stronger, more resilient renewable energy infrastructure when you choose superior cable management. These solutions protect your critical wiring from the harshest conditions. They ensure your solar panels and wind turbines operate efficiently for decades. By preventing failures and reducing maintenance, you create systems that can withstand environmental challenges. This robust infrastructure is essential for the widespread adoption of clean energy. It supports a reliable and sustainable power grid for the future.

Self-locking stainless steel cable ties are indispensable for the sustained growth of solar and wind energy. You gain robust cable management solutions for demanding renewable applications. Their fundamental role helps you build a reliable, sustainable energy future.

FAQ

Why should you choose stainless steel cable ties for solar installations?

You choose them for superior durability. They resist UV, extreme temperatures, and corrosion. This ensures long-lasting performance in harsh outdoor environments.

Which grades of stainless steel are best for renewable energy applications?

You should use 304 or 316 grade stainless steel. These grades offer excellent corrosion resistance. Grade 316 performs especially well in coastal or chemically exposed areas.

How does the self-locking mechanism work in these cable ties?

The tie’s head contains a ratchet or ball bearing. It grips the band as you pull it tight. This creates a secure, tamper-resistant, and permanent hold.

Post time: Jan-20-2026