Global demand for self-locking stainless steel cable ties is surging. Market projections indicate significant growth, with some analyses forecasting a Compound Annual Growth Rate of up to 7.0% for these essential components. Xinjing strategically optimizes its supply chain to meet this increasing need for Stainless Steel Cable Ties.

Key Takeaways

- Xinjing makes sure its stainless steel cable ties are always available. It uses smart sourcing and good shipping to avoid delays.

- Xinjing’s cable ties are very strong and last a long time. They use good stainless steel and pass many tests for quality.

- Xinjing’s smart supply chain helps keep prices fair. This means customers get good products without paying too much.

Strengthening the Supply Chain for Self-Locking Stainless Steel Cable Ties

Strategic Sourcing of Premium Stainless Steel

Xinjing prioritizes the foundation of its products: premium stainless steel. The company implements a rigorous supplier evaluation process. This process ensures all raw materials meet stringent quality benchmarks. Key performance indicators guide the selection of stainless steel suppliers. These indicators include compliance with international standards. For example, ASTM F2051 specifies mechanical and material requirements. ISO 9001 validates quality management systems. AISI 304/316 Certification ensures proper alloy composition for corrosion resistance. Xinjing also requires verification through third-party test reports. These reports, from entities like SGS or TÜV, confirm tensile strength (50–120 lbs), salt spray test results (minimum 480 hours for 316-grade), and weld integrity.

Operational performance metrics further refine supplier selection.

| Metric | Recommended Benchmark | Rationale |

|---|---|---|

| On-Time Delivery Rate | ≥95% | Ensures supply chain continuity and project scheduling accuracy. |

| Response Time to Inquiries | ≤4 hours | Reflects customer service commitment and operational agility. |

| Reorder Rate | ≥15% | Indicates client satisfaction and product consistency. |

| Factory Size | ≥3,000 m² | Suggests scalability and investment in infrastructure. |

Xinjing also assesses suppliers for their customization and R&D capabilities. This includes the ability to provide custom designs for specialized applications. Examples include aerospace or offshore industries. Suppliers must also demonstrate in-house tooling, CNC machinery, and dedicated R&D teams. These capabilities allow adaptation of tie dimensions, head configurations, or locking mechanisms. Additional criteria include scalability, product certification (e.g., RoHS, ISO), and investment in R&D for product improvements. The durability and performance of ties under environmental stresses are crucial. Xinjing also considers the total cost of ownership, including lifespan and maintenance. Xinjing sources various cold-rolled and hot-rolled stainless steel types. These include 200, 300, and 400 series, duplex steel, and heat-resistant steel. The company also procures precision cold-rolled hard stainless steel and decorative stainless steel plates. Xinjing partners with reputable mills like Baoxin, Zhangpu, TISCO, and Lianzhong for materials such as 304, 316L, and 430.

Advanced Manufacturing for Precision and Volume

Xinjing employs advanced manufacturing techniques to ensure precision and high volume for its products. The company utilizes precise stamping and molding injection processes. This expertise extends to engineering plastic Polyamide 6,6. Xinjing possesses rich experience and specialization in precise molding for this material. The company operates advanced molding facilities. An outstanding R&D teamwork supports these operations. This team continuously refines production methods. These technologies enable Xinjing to produce self-locking stainless steel cable ties with exceptional accuracy. The in-house processes include slitting, multi-blanking, cut-to-length, stretcher leveling, shearing, and surface treatment. These capabilities ensure consistent quality and allow for efficient, large-scale production.

Optimized Logistics for Global Distribution

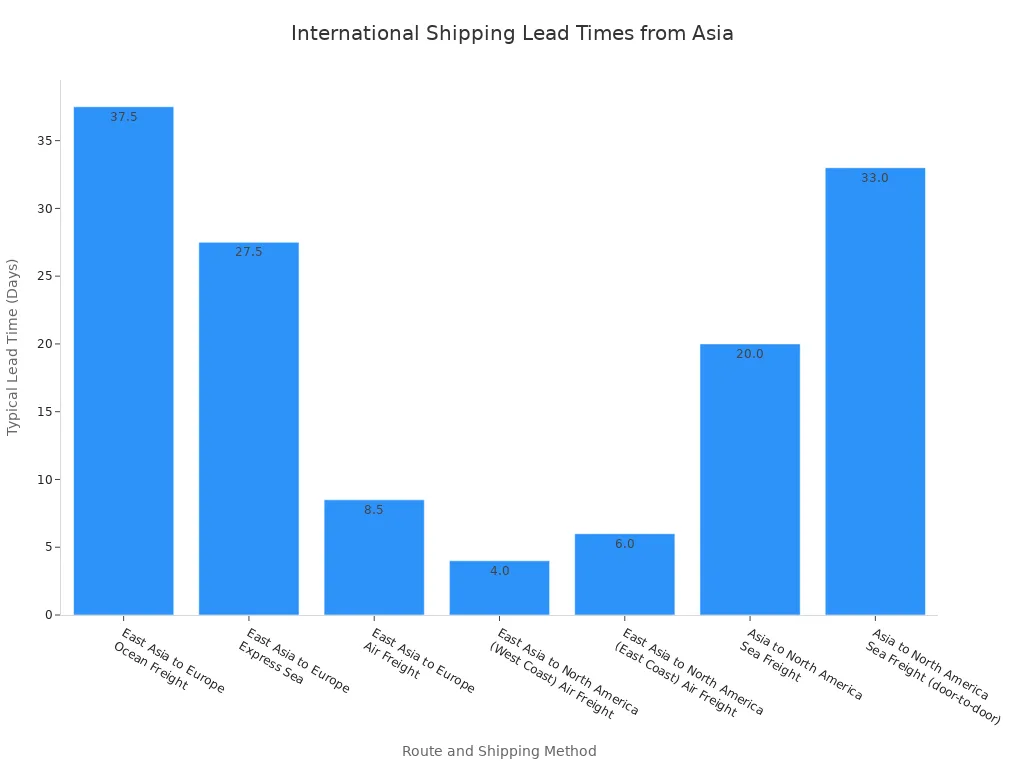

Xinjing’s strategic location in Ningbo, a major port city in China, provides a significant logistical advantage. The company has optimized its logistics network for global distribution. This ensures efficient and timely delivery of products worldwide. Xinjing leverages various shipping methods to meet diverse customer needs.

| Route (Origin to Destination) | Shipping Method | Typical Lead Time |

|---|---|---|

| East Asia to Europe | Ocean Freight (port-to-port) | 30-45 days |

| East Asia to Europe | Express Sea Options | 20-35 days |

| East Asia to Europe | Air Freight (door-to-door) | 7-10 days |

| East Asia to North America (West Coast) | Air Freight (port-to-port) | 3-5 days |

| East Asia to North America (East Coast) | Air Freight (door-to-door) | 5-7 days |

| Asia to North America | Sea Freight (port-to-port) | 15-25 days |

| Asia to North America | Sea Freight (door-to-door) | 19-47 days |

This comprehensive approach to logistics minimizes lead times. It also enhances reliability for international shipments. Xinjing’s optimized supply chain ensures customers receive their self-locking stainless steel cable ties promptly. This global reach reinforces Xinjing’s position as a reliable supply chain partner.

Xinjing’s Enhanced Supply Chain: Delivering Value in Self-Locking Stainless Steel Cable Ties

Unwavering Product Availability and Reduced Lead Times

Xinjing’s robust supply chain ensures consistent product availability and significantly reduces lead times for customers. Many industrial sectors often face product unavailability. This can stem from supply shortages caused by geopolitical conflicts, natural disasters, or supplier bankruptcy. Logistics and transportation issues, such as port congestion or shipping container shortages, also create disruptions. Inefficient manual processes and poor inventory management further complicate matters. Xinjing proactively addresses these challenges. The company’s strategic sourcing and optimized logistics network minimize these risks. This approach guarantees a steady flow of materials and finished goods. Customers receive their orders promptly, avoiding costly delays.

Superior Quality and Durability of Self-Locking Stainless Steel Cable Ties

Xinjing commits to delivering superior quality and durability in its self-locking stainless steel cable ties. The company ensures material verification through mill test certificates for 304/316 grade stainless steel. It also adheres to ISO 9001 standards. Third-party tensile test reports confirm mechanical strength, meeting specifications like IEC 62275. Visual inspections and repeated tightening cycles verify lock integrity. These ties also demonstrate exceptional environmental resistance. Salt spray test results (ASTM B117) confirm their resilience. They also possess high chloride exposure ratings and wide temperature ranges.

Xinjing’s stainless steel cable ties offer remarkable longevity. They can last from 10 to 30 years, far exceeding the 1-2 year lifespan of standard nylon ties outdoors. These ties maintain tensile strength and flexibility throughout their service life. They are completely immune to ultraviolet damage, making them ideal for outdoor installations. They also withstand extreme temperatures, from -80°F to 1000°F. This makes them suitable for arctic or desert applications. Unlike plastic ties, they resist virtually all chemical attacks from acids, bases, and solvents. Their superior tensile strength handles dynamic loads without degradation. This eliminates common failure modes seen in plastic ties, such as brittleness from UV exposure or micro-cracks from temperature cycling.

Competitive Pricing and Cost Efficiency

Xinjing’s enhanced supply chain directly translates into competitive pricing and significant cost efficiency for its customers. Companies that optimize their supply chains typically achieve an average 15% reduction in supply chain costs. Focused efforts can even lead to reductions of up to 25%. Xinjing achieves these savings by minimizing waste and optimizing processes. This prevents overproduction and underproduction. The company streamlines operations in warehousing, production, and logistics. This lowers infrastructure costs and boosts production rates.

Xinjing also automates tasks like order processing and inventory management. This decreases labor costs and improves overall efficiency. A streamlined approach ensures the sourcing and maintenance of high-quality raw materials. This positively impacts the final product’s quality. Xinjing’s strategic partnerships and digital supply chain technologies further enhance its competitive edge. These technologies provide real-time connectivity with suppliers. They also offer greater visibility and control over the supply chain. This comprehensive strategy allows Xinjing to offer high-value self-locking stainless steel cable ties at competitive prices.

Future-Proofing the Supply of Self-Locking Stainless Steel Cable Ties

Continuous Innovation and R&D

Xinjing invests significantly in continuous innovation and research and development. The company adopts advanced manufacturing technologies to enhance its products. Additive Manufacturing (3D printing) transforms production. It allows for complex geometries and intricate designs, reducing material waste and shortening lead times. Automation and robotics streamline manufacturing processes. These technologies increase efficiency, consistency, and speed, particularly for high-volume production. Digital Twin technology creates virtual simulations of fasteners. This helps analyze performance under real-world conditions. These innovations optimize design and ensure compliance with industry standards.

Sustainable Practices in Production and Sourcing

Xinjing commits to sustainable practices in production and sourcing. Stainless steel manufacturing is inherently environmentally friendly. It primarily uses scrap metal, significantly reducing CO2 emissions compared to raw ore. The material recycles repeatedly without quality loss. Xinjing adheres to stringent air quality, water management, and waste disposal regulations. The company implements circular economy principles. These practices minimize waste generation, reduce environmental impact, and lower operational costs. They also enhance brand reputation and build supply chain resilience.

Adapting to Evolving Market Needs

Xinjing actively adapts to evolving market needs. Buyers increasingly prioritize high-quality, durable, and eco-friendly options. There is a significant demand for certifications and versatile products. The market also seeks innovative solutions like metal-detectable cable ties for enhanced safety and industrial compliance. Xinjing’s robust supply chain helps navigate geopolitical factors. These factors include trade wars, sanctions, and political instability. The company ensures a steady supply of self-locking stainless steel cable ties. This proactive approach maintains market relevance and customer satisfaction.

Xinjing’s enhanced supply chain directly addresses the surging market demand and customer needs for self-locking stainless steel cable ties. The company stands prepared to meet both current and future challenges with its robust and highly efficient supply network. We invite you to explore Xinjing’s comprehensive range of products today.

FAQ

Are Xinjing’s self-locking stainless steel cable ties reusable?

No, you should not reuse them. The engineered self-locking mechanism provides a permanent, secure hold. Releasing it can weaken the tie, compromising its reliability.

What makes Xinjing’s self-locking stainless steel cable ties durable?

Xinjing uses premium 304/316 stainless steel. Rigorous testing confirms their strength and resistance to corrosion, UV, and extreme temperatures. They last 10-30 years.

How does Xinjing ensure consistent product availability?

Xinjing employs strategic sourcing and optimized global logistics. This robust supply chain minimizes disruptions. It guarantees a steady flow of materials and finished goods.

What types of stainless steel does Xinjing utilize for its cable ties?

Xinjing primarily uses 304 and 316L stainless steel. These grades offer excellent corrosion resistance and strength. The company sources from top mills.

Post time: Nov-27-2025