You want stainless steel cable ties that offer both strength and flexibility. Choose Durable Stainless Steel Cable Ties to secure loads safely while allowing for easy installation. Consider your load capacity, environment, and handling requirements. The right balance ensures reliable performance in demanding applications.

Key Takeaways

- Choose stainless steel cable ties that balance strength and flexibility to ensure easy installation and reliable performance in tough conditions.

- Select the right material grade—use 316 stainless steel for harsh environments like marine or chemical settings, and 304 for general indoor or outdoor use.

- Install cable ties properly using tensioning tools, leave some slack for movement, and inspect regularly to keep your bundles secure and safe.

Understanding Strength and Flexibility in Stainless Steel Cable Ties

What Strength Means for Stainless Steel Cable Ties

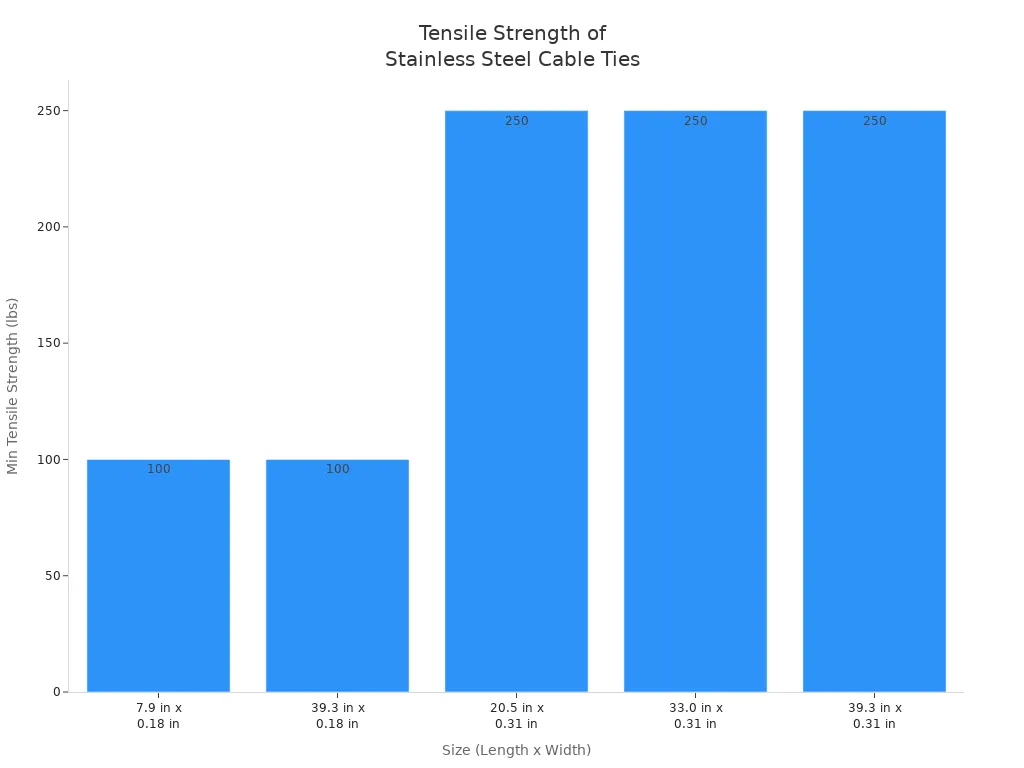

When you select stainless steel cable ties, you need to understand how strength is measured. Industry standards use minimum loop tensile strength to show how much load a cable tie can handle before breaking. This value depends on the width and thickness of the tie. For example, stainless steel cable ties made from 304 or 316 grades can have minimum loop tensile strengths from 100 lbs to 250 lbs, depending on their size. The table below shows typical values for heavy-duty applications:

| Size (Length x Width) | Minimum Tensile Strength (lbs) | Max Bundle Diameter |

|---|---|---|

| ~7.9 in x 0.18 in | 100 | ~2.0 in |

| ~39.3 in x 0.18 in | 100 | ~12.0 in |

| ~20.5 in x 0.31 in | 250 | ~6.0 in |

| ~33.0 in x 0.31 in | 250 | 10 in |

| ~39.3 in x 0.31 in | 250 | ~12.0 in |

You can also see the strength differences in this chart:

Why Flexibility Matters During Installation

Flexibility plays a key role when you install stainless steel cable ties, especially in tight or confined spaces. Rigid ties can make installation more difficult, requiring special tools and careful handling. Low-profile or flat-head designs help you thread the tie parallel to the bundle, reducing snagging and making the process smoother. If you work in restricted areas, you will find that flexible ties allow for easier adjustments and faster installation.

Tip: Choose cable ties with a design that matches your installation environment to save time and reduce frustration.

The Importance of Achieving the Right Balance

You need to balance strength and flexibility to ensure reliable performance. Industry guidelines suggest matching the cable tie’s construction to your application. For example, a 1×19 construction offers high strength but less flexibility, while a 7×19 construction provides more flexibility with moderate strength. Always consider your load, environment, and safety needs. Regular inspection and proper installation help maintain the effectiveness of your stainless steel cable ties over time.

Key Factors for Choosing Stainless Steel Cable Ties

Material Grades: 304 vs. 316 Stainless Steel

When you choose stainless steel cable ties, you need to consider the material grade. The two most common options are 304 and 316 stainless steel. Both grades offer excellent strength and durability, but they differ in corrosion resistance and mechanical properties. The table below highlights the main differences:

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Molybdenum Content | None | 2.0–2.5% |

| Nickel Content | 8.0–10.5% | 10.0–13.0% |

| Chromium Content | 18.0–19.5% | 16.5–18.5% |

| Ultimate Tensile Strength | ~73,200 psi | ~79,800 psi |

| Tensile Yield Strength | ~31,200 psi | ~34,800 psi |

| Hardness (Rockwell B) | 70 | 80 |

| Elongation at Break | 70% | 60% |

| Corrosion Resistance | Excellent | Superior (especially vs. chlorides) |

| Weldability | High | Good |

| Formability | Very Good | Good |

316 stainless steel contains molybdenum, which gives it superior resistance to chlorides and harsh chemicals. You should select 316 stainless steel cable ties for marine, coastal, or chemical processing environments. For most indoor or general outdoor uses, 304 stainless steel provides reliable performance and cost-effectiveness.

Thickness, Width, and Hardness Ratings

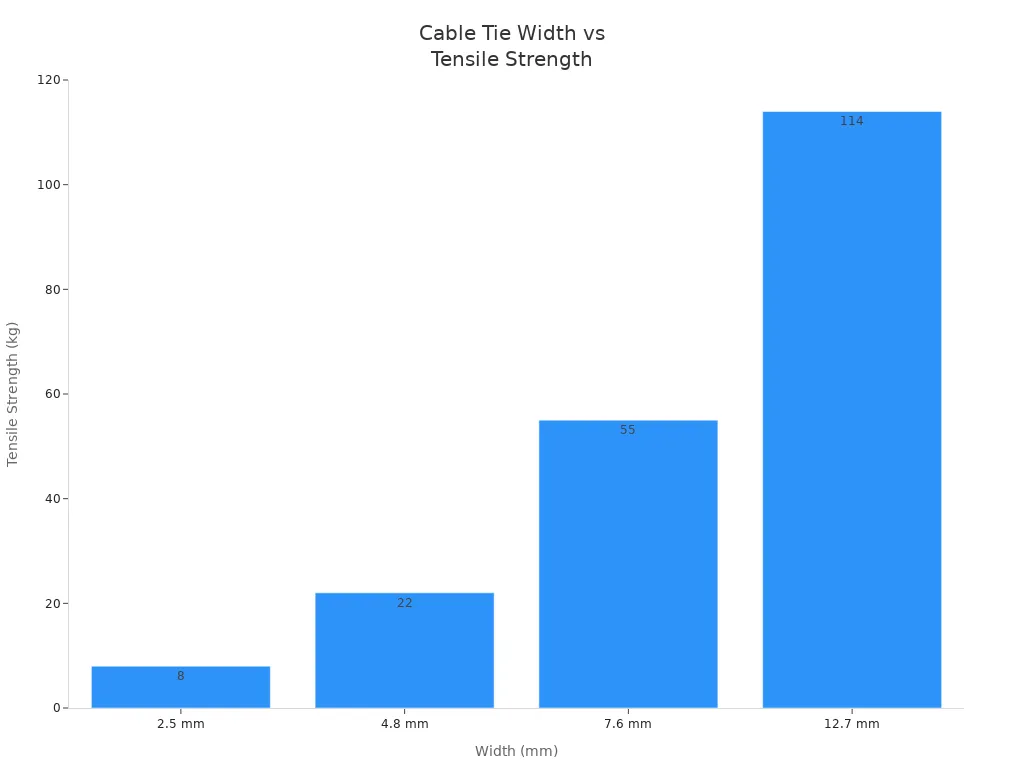

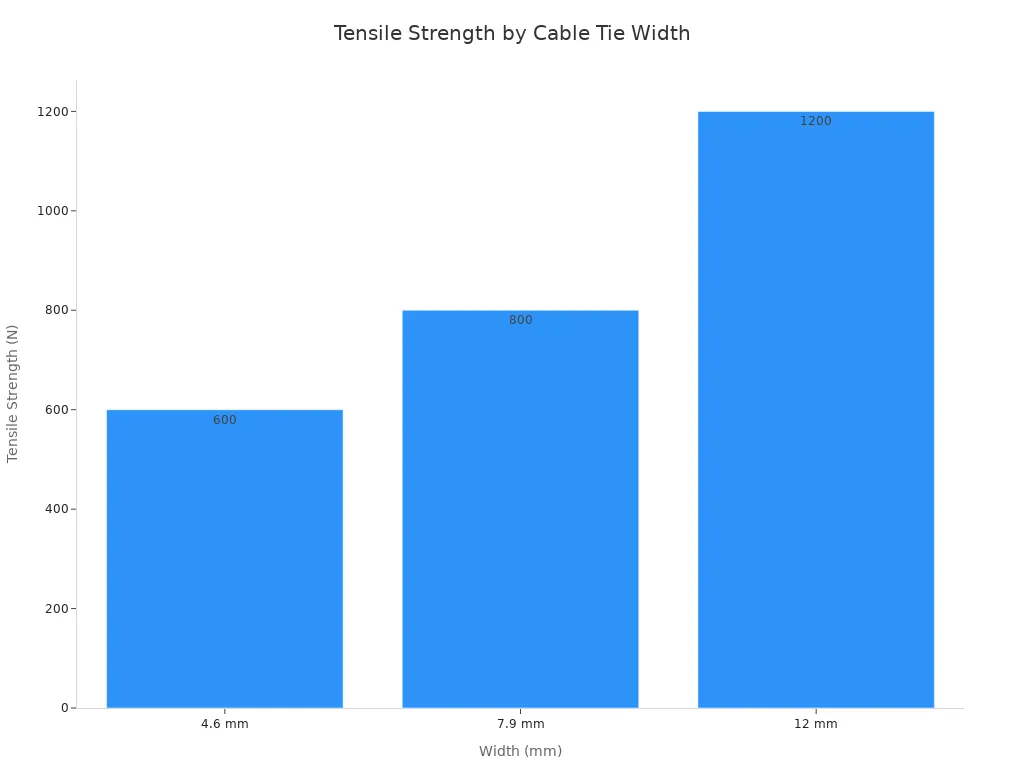

The thickness and width of a cable tie directly impact its load-bearing capacity. Wider and thicker ties can handle heavier loads and provide greater strength. The following chart shows how increasing the width of stainless steel cable ties raises their tensile strength:

You can also refer to this table for a quick overview:

| Width (mm) | Tensile Strength (kg) | Typical Use Case |

|---|---|---|

| 2.5 | 8 | Light objects, small cables |

| 3.6 | 18 | Medium load applications |

| 4.8 | 22 | Heavier loads |

| 10-12 | >40 | Heavy-duty industrial use |

Hardness ratings, such as Rockwell B, indicate how resistant the tie is to deformation. Higher hardness means better resistance to wear and mechanical stress. You should always match the thickness, width, and hardness to your application’s load and safety requirements.

Application-Based Recommendations for Strength and Flexibility

You need to match the cable tie’s properties to your specific environment and application. For marine, offshore, or chemical plant installations, 316 stainless steel cable ties offer the best protection against corrosion and provide high mechanical strength. In these settings, you should prioritize both strength and corrosion resistance.

For heavy electrical cables in outdoor installations, select cable ties with these specifications:

| Specification Aspect | Details |

|---|---|

| Material | Stainless Steel grades 304 and 316 (316 preferred for superior corrosion resistance) |

| Size | Typical size: 250×4.6 mm |

| Tensile Strength | Approximately 667 N (150 lbs) |

| Temperature Range | -80°C to +500°C |

| Features | UV resistant, fireproof, halogen free |

| Locking Mechanism | Self-locking ratchet or roller lock type |

| Corrosion Resistance | High resistance to moisture, saltwater, chemicals, and oxidation |

| Suitable Environments | Outdoor, marine, offshore, harsh and demanding conditions |

Tip: For marine applications, always choose 316 stainless steel cable ties to ensure long-term reliability and safety. Their superior corrosion resistance and higher strength make them ideal for harsh environments.

In less aggressive environments, such as indoor cable management or general industrial use, 304 stainless steel cable ties provide a balance of strength, flexibility, and cost efficiency.

Practical Tips for Testing and Installation

Proper installation ensures that your stainless steel cable ties deliver both strength and flexibility. Use cable tie tensioning tools to apply the correct tension. These tools help you avoid over-tightening, which can damage the tie or the bundled items. They also cut off excess tail flush with the head, preventing sharp edges.

- Always leave a small amount of slack to allow for cable expansion or movement.

- Distribute ties evenly along the bundle to prevent stress concentration.

- Regularly inspect cable ties for signs of wear, corrosion, or damage, especially in harsh environments.

- Replace any damaged ties promptly to maintain system integrity.

Note: Routine maintenance and correct installation techniques extend the life of your cable ties and ensure ongoing performance.

By considering these key factors, you can confidently select stainless steel cable ties that meet your strength and flexibility needs, ensuring safety and durability in any application.

You achieve long-lasting results when you match stainless steel cable ties to your application’s demands. Select the right grade, width, and tensile strength for your environment. Proper installation and regular inspection ensure a lifespan of 5 to 10 years, even in harsh conditions.

FAQ

What environments require 316 stainless steel cable ties?

You should use 316 stainless steel cable ties in marine, coastal, or chemical environments. These ties resist corrosion from saltwater and harsh chemicals.

Tip: Always check your environment before choosing a grade.

How do you ensure proper installation of stainless steel cable ties?

You should use a tensioning tool for consistent results.

- Apply correct tension

- Trim excess tail

- Inspect ties regularly

Can you reuse stainless steel cable ties?

No, you should not reuse stainless steel cable ties. Once you secure and cut them, they lose their locking ability and strength.

Note: Always use a new tie for each application.

Post time: Aug-06-2025