You demand reliability from stainless steel cable ties in environments where failure is not an option. Material grade directly impacts how these ties perform under stress, especially when exposed to saltwater, UV radiation, or harsh chemicals. Choosing corrosion resistance stainless steel cable ties helps you minimize replacement needs and ensures long-lasting cable stability.

Key Takeaways

- Choosing the right stainless steel grade ensures your cable ties stay strong and resist corrosion in different environments.

- 304 stainless steel cable ties offer good strength and cost-effectiveness for general industrial use.

- 316L and Duplex stainless steel cable ties provide better corrosion resistance and higher strength for harsh marine, chemical, and extreme industrial settings.

Why Material Grade Matters for Stainless Steel Cable Ties

What Are Stainless Steel Cable Ties

You use stainless steel cable ties to secure cables, wires, and hoses in demanding environments. These ties offer high strength, durability, and resistance to extreme temperatures. Unlike plastic ties, stainless steel cable ties do not crack or degrade when exposed to sunlight, chemicals, or moisture. You can find them in industries such as oil and gas, marine, automotive, and electrical. Their ability to withstand harsh conditions makes them essential for safety and reliability.

Impact of Material Grade on Performance

The grade of stainless steel you choose directly affects the performance of your cable ties. Each grade brings unique mechanical and chemical properties. The table below highlights key differences:

| Property / Steel Type | 304 Stainless Steel | 316L Stainless Steel | Duplex Stainless Steel |

|---|---|---|---|

| Microstructure | Austenitic | Austenitic | Mixed Austenite and Ferrite (approx. 50:50) |

| Yield Strength (annealed) | ~210 MPa | Similar to 304 | Roughly twice that of 304 and 316L |

| Corrosion Resistance | Good general corrosion resistance | Better resistance, especially to chlorides | Superior resistance to chloride stress corrosion cracking |

| Impact on Cable Tie Performance | Adequate strength and corrosion resistance for general use | Better durability in acidic and chloride environments | Best strength and corrosion resistance, ideal for harsh environments |

When you select the right material grade, you ensure your stainless steel cable ties maintain their strength and resist corrosion over time. Grade 304 works well for general industrial use. Grade 316L, with added molybdenum, stands up to saltwater and harsh chemicals, making it ideal for marine and chemical settings. Duplex stainless steel offers the highest strength and corrosion resistance, perfect for extreme industrial environments. By matching the grade to your application, you protect your cables and maintain safety.

Performance Benefits of 304, 316L, and Duplex Stainless Steel Cable Ties

304 Stainless Steel: Cost-Effective Strength and Versatility

When you choose 304 stainless steel cable ties, you get a balance of strength, durability, and affordability. These ties deliver a tensile strength of about 600 MPa, which means they can handle heavy loads without stretching or breaking. The Rockwell hardness of 70B ensures that your ties resist deformation, even when exposed to tough industrial conditions. You can rely on 304 stainless steel cable ties in chemical plants, construction sites, and outdoor installations. They outperform nylon ties by offering higher strength and much better resistance to corrosion. You also benefit from their ability to maintain mechanical properties over time, so you do not need to worry about frequent replacements.

Tip: 304 stainless steel cable ties work well for most general-purpose applications, making them a smart choice when you need reliable performance at a reasonable cost.

316L Stainless Steel: Enhanced Corrosion Resistance for Harsh Environments

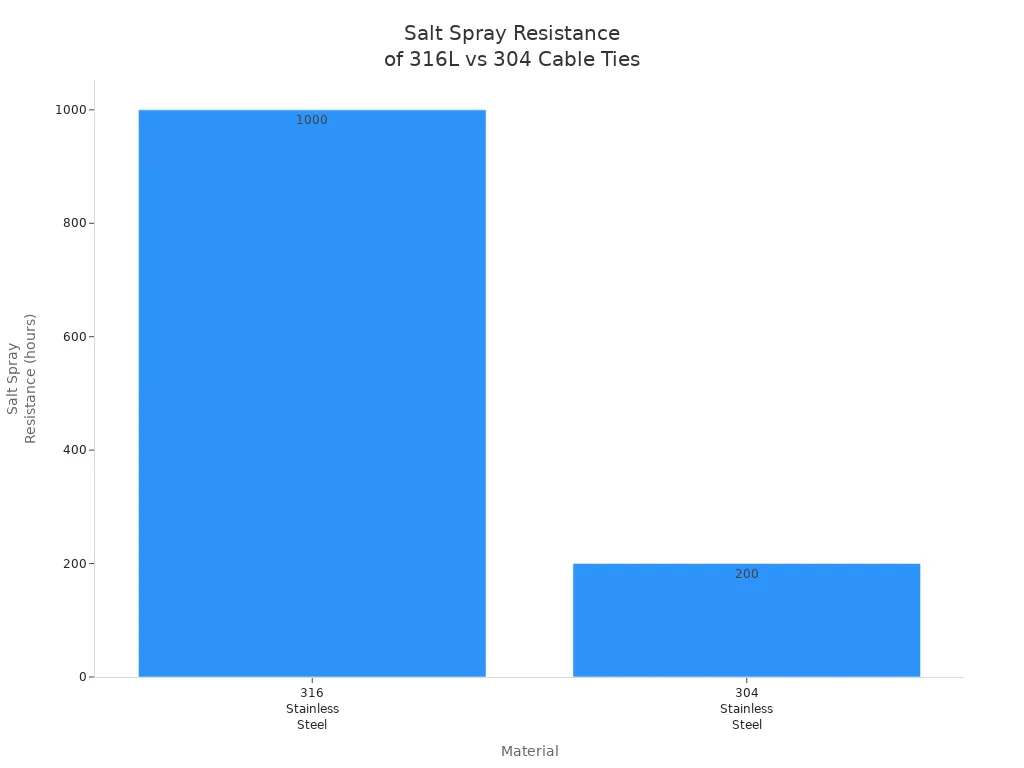

If you operate in marine or chemical environments, 316L stainless steel cable ties offer superior protection. The addition of 2% molybdenum boosts their resistance to chloride ions and chemical attacks. Field and laboratory tests show that 316L stainless steel stands up to saltwater exposure for over a year, even when iron-oxidizing bacteria are present. You can use these ties in estuaries, offshore platforms, and chemical processing plants without worrying about rapid corrosion. In chemical facilities, 316L stainless steel cable ties outperform 304 by resisting pitting and surface damage, even after 1,000 hours in salt spray tests.

You also benefit from their ability to maintain strength under extreme temperatures and vibration. This means your cable management system stays secure, even in the most demanding settings.

Duplex Stainless Steel: Superior Strength and Durability

Duplex stainless steel cable ties give you the highest level of strength and durability. The unique microstructure, which combines austenite and ferrite, provides twice the yield strength of 304 and 316L. You can count on these ties to hold up under heavy loads and repeated stress. Fatigue tests show that duplex stainless steel wires maintain their endurance, even after decades of service. If your application involves constant vibration or high mechanical stress, duplex stainless steel cable ties will not let you down. They also resist corrosion in aggressive environments, making them ideal for offshore, petrochemical, and heavy industrial use.

Note: Duplex stainless steel cable ties are your best option when you need maximum strength and long-term reliability in extreme conditions.

Comparison of 304, 316L, and Duplex Stainless Steel Cable Ties

You can use the table below to compare the key performance features of each stainless steel cable tie grade:

| Feature | 304 Stainless Steel | 316L Stainless Steel | Duplex Stainless Steel |

|---|---|---|---|

| Tensile Strength | ~600 MPa | ~600 MPa | Up to 2x 304/316L |

| Corrosion Resistance | Excellent (general) | Superior (chlorides, acids) | Outstanding (all environments) |

| Fatigue Resistance | High | High | Exceptional |

| Cost | Most cost-effective | Higher | Highest |

| Best Use | General industry, outdoor | Marine, chemical, food | Offshore, heavy industry |

When you select the right grade, you ensure your cable ties deliver the performance your application demands. 304 stainless steel cable ties offer cost-effective strength for most uses. 316L stainless steel cable ties provide enhanced corrosion resistance for harsh environments. Duplex stainless steel cable ties deliver unmatched strength and durability for the toughest jobs.

Real-World Applications of Stainless Steel Cable Ties

304 Stainless Steel Cable Ties in General Industry

You often see 304 stainless steel cable ties in factories, electrical installations, and automotive workshops. These ties secure cables, wires, and hoses where strength and durability matter. Many industries choose them because they resist high temperatures and wear, making them ideal for packaging, storage, and transport.

- Oil and gas plants use them to bundle cables exposed to heat.

- Electrical and HVAC technicians rely on them for long-lasting cable management.

- Automotive factories use them to prevent damage or scattering of valuable parts.

You can maintain these ties easily. Use proper tensioning tools and check them regularly. Their corrosion resistance and long lifespan mean you spend less time on maintenance compared to plastic ties.

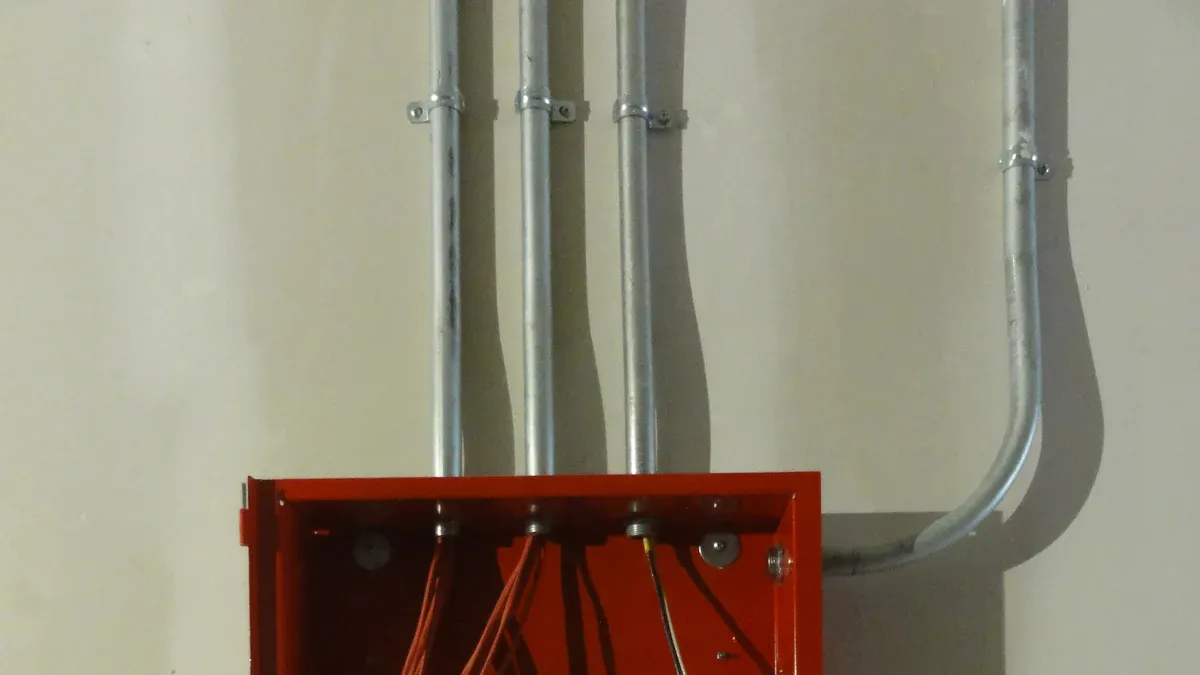

316L Stainless Steel Cable Ties in Marine and Chemical Settings

You need 316L stainless steel cable ties when working near saltwater or chemicals. Offshore oil platforms use them to secure electrical cables, pipelines, and insulation. These ties keep lighting and safety systems running, even with constant exposure to seawater and humidity.

- Drilling platforms use them to organize control cables and hoses.

- Chemical plants rely on them to fasten pipelines and structural components.

Their enhanced corrosion resistance ensures reliable performance in harsh marine and chemical environments.

Duplex Stainless Steel Cable Ties in Extreme Industrial Environments

You choose duplex stainless steel cable ties for the toughest jobs. Their unique structure gives them twice the strength of standard grades.

| Property | Value Range | Benefit in Harsh Environments |

|---|---|---|

| Yield Strength | 650–1050 MPa | Resists heavy mechanical loads |

| Corrosion Resistance (PREN) | 25–40 | Prevents pitting and cracking |

These ties perform well in oil and gas, offshore, and chemical processing industries. They handle both high stress and corrosive agents, ensuring your installations remain secure and reliable.

You gain reliable fastening by selecting the right stainless steel grade for your environment. Review the table below to compare key features:

| Grade | Corrosion Resistance | Strength | Best Use |

|---|---|---|---|

| 304 | Good | High | General industry |

| 316L | Superior | High | Marine, chemical |

| Duplex | Outstanding | Highest | Extreme industry |

FAQ

What environments require 316L stainless steel cable ties?

You should use 316L stainless steel cable ties in marine, chemical, or coastal environments. These ties resist saltwater and harsh chemicals better than other grades.

How do duplex stainless steel cable ties improve safety?

Duplex stainless steel cable ties provide higher strength and superior corrosion resistance. You can secure heavy loads and critical systems with confidence in extreme industrial settings.

Can you reuse stainless steel cable ties?

You cannot reuse most stainless steel cable ties. They feature a locking mechanism designed for single-use applications to ensure maximum security and reliability.

Tip: Always use new cable ties for each installation to maintain safety standards.

Post time: Aug-01-2025