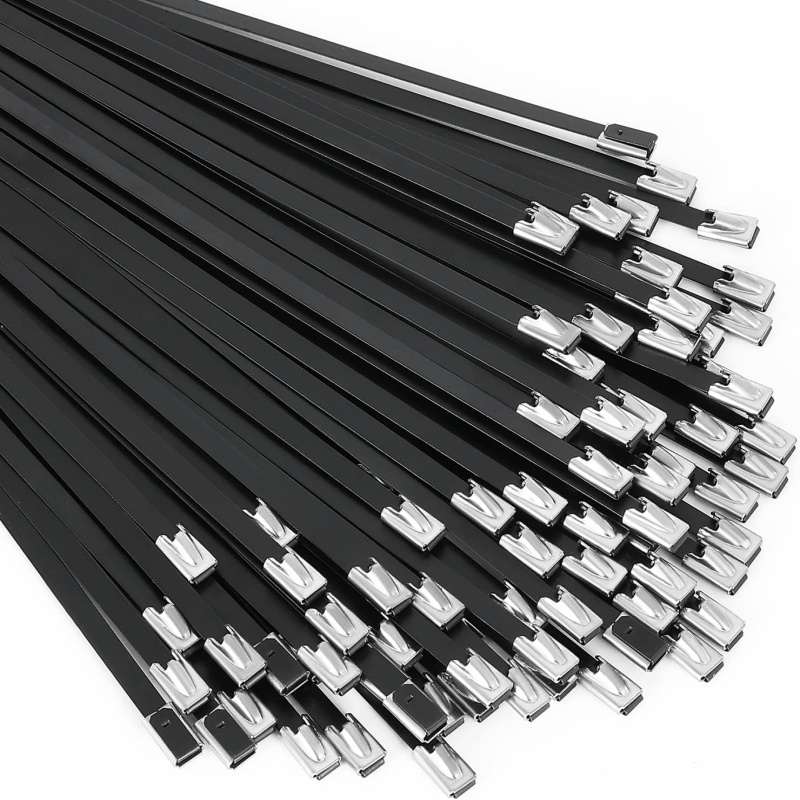

You face demanding conditions in industries like automotive, power plants, and metal processing, where temperatures can climb above 300°F. Stainless Steel Cable Ties, especially grades 321 and 316Ti, offer unmatched stability and strength.

Key Takeaways

- 321 and 316Ti stainless steel cable ties resist extreme heat and corrosion better than plastic or standard stainless steel ties, making them ideal for harsh environments.

- Titanium in 321 and 316Ti grades stabilizes the metal, preventing corrosion and maintaining strength even at temperatures above 800°C.

- These cable ties are trusted in automotive, aerospace, and energy industries for their durability, safety, and long-term reliability under tough conditions.

Challenges for Stainless Steel Cable Ties in High-Temperature Environments

Common Failures of Standard Cable Ties Under Hea

You encounter several risks when using standard cable ties in high-temperature settings. Plastic ties, especially those made from nylon, begin to soften and lose strength above 185°F (85°C). If exposed to even higher temperatures, these ties can melt or deform, causing cables to slip or disconnect. Over-tightening plastic ties in hot environments often leads to cracking and premature failure. Regular inspection becomes necessary, as heat and UV exposure can make plastic brittle and prone to breaking.

| Failure Point | Description | Temperature Thresholds (°F/°C) | Notes |

|---|---|---|---|

| Softening & Deformation | Plastic ties lose strength and deform under heat stress | Above 185°F (85°C) for standard nylon | Heat-stabilized nylon performs better but still has limits |

| Loss of Tensile Strength | Reduced ability to hold loads due to heat exposure | Begins above 185°F (85°C) standard nylon | Heat-stabilized nylon maintains integrity up to 221°F (105°C) continuous use |

| Melting | Complete failure by melting | Around 482°F (250°C) for nylon | Heat-stabilized nylon shares melting point but can withstand short-term exposure to 284°F (140°C) |

| Over-tightening | Excessive tension causes premature failure, especially when combined with heat | N/A | Use of tensioning tools recommended to avoid this failure mode |

| UV and Chemical Degradation | Environmental factors cause brittleness and cracking | N/A | Regular inspection advised to detect degradation early |

Material Limitations: Plastic vs. Standard Stainless Steel Grades

You must consider material limitations when selecting cable ties for extreme environments. Nylon cable ties, even when heat stabilized, only withstand continuous exposure up to about 250°F (121°C). In contrast, Stainless Steel Cable Ties operate reliably from –328°F to 1000°F (–200°C to 538°C). This wide temperature range makes them ideal for automotive, energy, and industrial applications.

Plastic ties degrade quickly in harsh conditions, losing tensile strength and flexibility. Stainless Steel Cable Ties resist corrosion, abrasion, and mechanical stress. You benefit from their ability to maintain tension and integrity, even when exposed to vibration, pressure, and chemical agents. Offshore oil platforms, chemical plants, and desert installations rely on stainless steel for long-term safety and durability.

Tip: Always match your cable tie material to the temperature and environmental demands of your application. Stainless steel offers superior performance where plastic fails.

Why 321 and 316Ti Stainless Steel Cable Ties Excel

Unique Properties and Heat Resistance of 321 Stainless Steel Cable Ties

You gain a significant advantage when you choose 321 stainless steel cable ties for high-temperature environments. The secret lies in the alloy’s unique composition. Titanium acts as a stabilizing element, forming stable carbides that bind carbon. This process prevents the formation of chromium carbides, which can weaken corrosion resistance at elevated temperatures. As a result, 321 stainless steel maintains its strength and resists oxidation even when exposed to temperatures up to 1500°F (816°C).

The typical composition of 321 stainless steel includes:

| Element | Typical Range in 321 Stainless Steel |

|---|---|

| Chromium | Approximately 17.0% to 19.0% |

| Nickel | Approximately 9.0% to 12.0% |

| Titanium | Minimum of 5 times the sum of Carbon and Nitrogen, up to 0.70% |

| Carbon | Up to 0.08% |

| Nitrogen | Up to 0.10% |

This combination, especially the titanium content, gives you excellent resistance to intergranular corrosion and oxidation. You can rely on 321 stainless steel cable ties to deliver consistent performance in environments where standard grades like 304 may fail.

Distinct Advantages of 316Ti Stainless Steel Cable Ties

When you need cable ties that can withstand both high temperatures and aggressive environments, 316Ti stainless steel cable ties stand out. The addition of 0.5–0.7% titanium forms stable titanium carbonitrides. These compounds capture carbon before it can form chromium carbides, which often lead to intergranular corrosion. This stabilization process ensures that 316Ti maintains its corrosion resistance and mechanical strength, even in the sensitization temperature range of 425–815°C.

You benefit from this titanium stabilization in several ways:

- Enhanced resistance to intergranular corrosion, especially after welding or prolonged heat exposure.

- Improved high-temperature stability, making these cable ties ideal for demanding industrial applications.

- Increased mechanical strength due to refined grain structure and resistance to grain growth.

Note: 316Ti stainless steel cable ties provide reliable performance in environments where both heat and corrosion pose significant challenges.

321 and 316Ti vs. 304 and 316: Performance Comparison

You often face a choice between different stainless steel grades for cable ties. Understanding how 321 and 316Ti compare to 304 and 316 helps you make the right decision for your application.

- 321 stainless steel cable ties offer superior creep resistance and stress rupture strength compared to 304 and 304L at elevated temperatures. You can use them in environments up to 816°C without worrying about loss of strength or oxidation.

- 316Ti stainless steel cable ties provide better resistance to intergranular corrosion than standard 316, especially after exposure to high temperatures or welding. The titanium addition ensures long-term stability and mechanical integrity.

| Grade | Max Service Temp (°C) | Creep Resistance | Intergranular Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|

| 304 | ~870 | Moderate | Moderate | General industrial |

| 316 | ~870 | Moderate | Good | Marine, chemical |

| 321 | ~816 | High | Excellent | High-temp, automotive, aerospace |

| 316Ti | ~870 | High | Excellent | Power plants, energy, chemical |

You get the best performance in extreme temperature and corrosive environments when you select 321 or 316Ti stainless steel cable ties over standard grades.

Real-World Applications: Automotive, Aerospace, and Energy Industries

You see the benefits of these advanced cable ties in some of the world’s most demanding industries. In automotive manufacturing, 321 stainless steel cable ties secure exhaust systems and engine components exposed to constant heat and vibration. Aerospace engineers rely on these ties for wiring and hydraulic lines that must perform flawlessly at high altitudes and temperatures.

In the energy sector, especially in power plants and refineries, 316Ti stainless steel cable ties hold up against both high temperatures and corrosive chemicals. Offshore oil platforms and chemical processing facilities also depend on these cable ties for long-term safety and reliability.

Tip: When you select stainless steel cable ties for critical applications, always consider the specific temperature and corrosion challenges of your industry. Choosing the right grade ensures safety, efficiency, and peace of mind.

You choose 321 and 316Ti Stainless Steel Cable Ties for extreme temperature environments because they deliver unmatched heat resistance and durability. The table below highlights their key advantages. For best results, use proper tensioning tools, trim excess tails, and schedule regular inspections to ensure long-term safety and reliability.

| Factor | 316Ti Stainless Steel Cable Ties | 321 Stainless Steel Cable Ties |

|---|---|---|

| Titanium Stabilization | Present | Present |

| Max Service Temp | Up to 900°C | Up to 870°C |

| Corrosion Resistance | Superior | Moderate, excels in oxidation resistance |

FAQ

What industries benefit most from 321 and 316Ti stainless steel cable ties?

You find these cable ties essential in automotive, aerospace, energy, and chemical processing industries. They deliver reliable performance in high-heat and corrosive environments.

How do you select the right stainless steel cable tie for your application?

You should consider temperature range, corrosion exposure, and mechanical stress. Consult technical data sheets or contact your supplier for expert guidance.

Where can you source high-quality 321 and 316Ti stainless steel cable ties?

You can partner with Xinjing Stainless Steel Co., Ltd. for reliable supply, technical support, and global distribution.

Tip: Always verify material certifications to ensure you receive genuine, high-performance stainless steel cable ties.

Post time: Aug-12-2025