Xinjing demonstrates an unwavering commitment to superior durability in every self-locking stainless steel cable ties we produce. We understand the critical importance of long-lasting performance for these components in demanding applications. Xinjing’s meticulous process guarantees exceptional longevity for our Stainless Steel Cable Ties, providing you with reliable solutions.

Key Takeaways

- Xinjing uses high-quality stainless steel. This makes cable ties strong. They resist rust and extreme heat.

- Xinjing makes cable ties with care. They use special tools. This ensures each tie locks well and holds tight.

- Xinjing tests all cable ties. They check for strength and quality. This means you get a reliable product.

Foundation of Durability: Material Excellence for Self-Locking Stainless Steel Cable Ties

You understand that the strength of any product begins with its raw materials. For self-locking stainless steel cable ties, this principle holds especially true. Xinjing prioritizes material excellence, establishing the core durability of every tie you receive.

Sourcing High-Grade Stainless Steel

We begin by sourcing only the highest-grade stainless steel. This critical first step ensures your cable ties possess inherent strength and resilience. You need materials that perform reliably in diverse environments. Consider the distinct advantages of specific stainless steel grades:

| Grade | Durability Characteristics |

|---|---|

| 304 Stainless Steel | Corrosion-resistant, fire-resistant, withstands heat up to 1000°F, offers higher tensile strength and longer life. |

| 316 Stainless Steel | Superior corrosion resistance, especially in marine environments, withstands corrosive marine air, performs well in extreme temperatures and corrosive environments. |

Both 304 and 316 grades are austenitic stainless steels. They maintain their integrity across a wide temperature range, from -80°C to +538°C (-112°F to +1000°F), and boast a melting point of 1400°C (2550°F). You gain excellent UV resistance and non-flammable properties with these materials. Xinjing’s expertise in stainless steel processing allows us to select the optimal grade for your specific application needs.

Advanced Material Preparation and Processing

High-grade raw material is only the beginning. Xinjing employs advanced preparation and processing techniques to enhance the material’s inherent properties. Our in-house capabilities include slitting, multi-blanking, cut-to-length, stretcher leveling, shearing, and various surface treatments. These processes refine the stainless steel, ensuring uniform thickness, optimal grain structure, and superior surface finish. This meticulous preparation prevents weak points and stress concentrations, which could compromise the cable tie’s performance. You benefit from a product where every detail contributes to its overall strength and longevity.

Engineering Corrosion Resistance

Corrosion poses a significant threat to the longevity of any metal product, especially in harsh industrial or outdoor settings. Xinjing engineers exceptional corrosion resistance into every cable tie. We achieve this through several strategic approaches:

- Higher-grade alloys: Utilizing materials like 316 stainless steel significantly enhances corrosion resistance, especially in harsh environments, compared to 304 stainless steel.

- Passivation: This process removes free iron from the surface, creating a protective oxide layer. This boosts corrosion resistance, particularly for outdoor or damp applications.

- Electropolishing: This technique achieves a smoother, mirror-like finish. It reduces micro-crevices where corrosive elements could accumulate, making it ideal for cleanroom or food processing settings.

- Powder Coating: This provides an additional protective barrier against scratches and corrosion. We often use it for aesthetic purposes or in visible applications.

These engineering strategies ensure your cable ties withstand challenging conditions. They resist oxidation, various corrosive media, and salt spray. This robust resistance directly contributes to the high tensile strength you expect. Self-locking stainless steel cable ties possess tensile strength ratings ranging from 200 to 900 lbs. This indicates the maximum load they can support before breaking. You can trust Xinjing’s cable ties to perform reliably, even in the most demanding environments.

Precision Manufacturing and Design Integrity of Self-Locking Stainless Steel Cable Ties

You understand that superior materials form the foundation, but precise manufacturing and intelligent design elevate a product to exceptional durability. Xinjing applies state-of-the-art techniques and meticulous engineering to every self-locking stainless steel cable ties you receive. This ensures each tie performs reliably and consistently.

State-of-the-Art Production Techniques

Xinjing employs advanced production techniques to guarantee the precision and quality of your cable ties. We begin with a sophisticated injection molding process. Here, nylon pellets melt and then inject into molds. This injection molding technique precisely shapes components like the flexible strap and the intricate locking mechanism. Molten nylon injects under high pressure into precision-engineered molds. This injection process ensures uniform material distribution and accurately replicates intricate details from the mold.

After molding, rigorous quality checks ensure product integrity. A tensile testing machine accurately measures the strength of cable ties. This ensures they withstand pull forces without breaking or slipping. Furthermore, a visual inspection system automatically detects defects. It identifies issues such as flash around the head, body, or tail, and spots short shots with an accuracy of ±1 mm. If the system finds a defect, the machine rejects the entire shot. This prevents sub-standard products from reaching you. We maintain quality through careful raw material selection, precise molding processes, and rigorous inspection procedures.

Engineered Self-Locking Mechanism

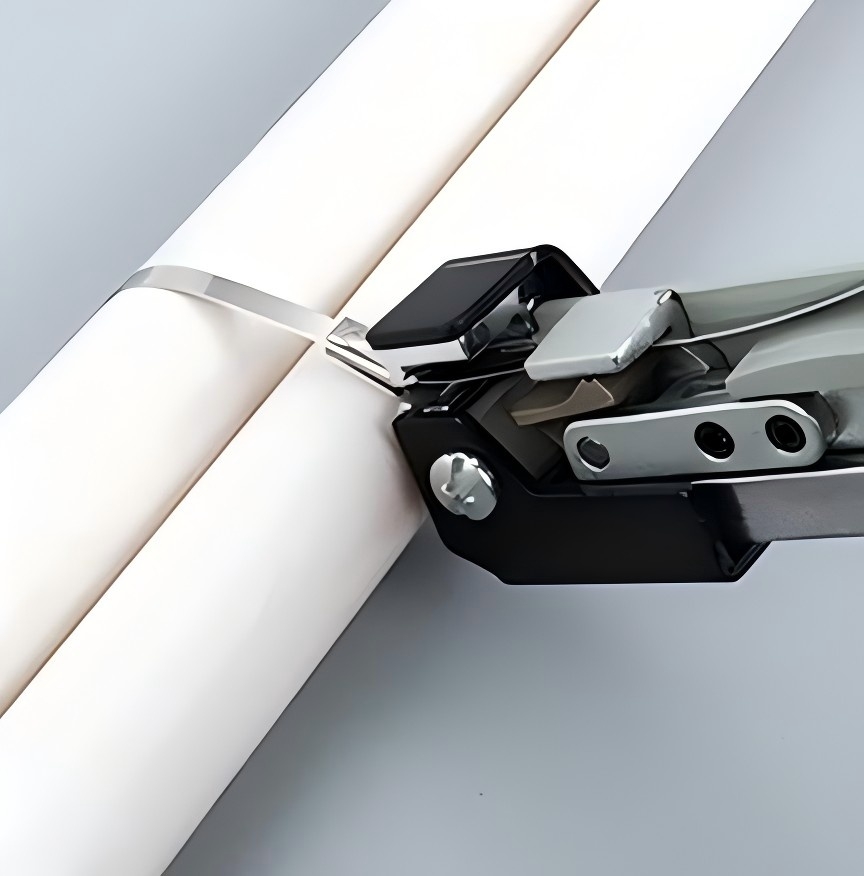

The self-locking mechanism is the heart of your cable tie’s functionality. Xinjing engineers this critical component for maximum security and ease of use. For stainless steel cable ties, the common self-locking mechanism is the ‘punch lock’. This design ensures a robust and permanent hold.

You benefit from a durable stainless steel locking mechanism. It ensures a reliable and long-lasting hold. Some designs feature a patented ball-locking mechanism. This provides unrivaled security, ensuring a tight and secure grip. It prevents slippage even under heavy loads or vibrations. The self-locking mechanism eliminates the need for additional tools. This saves you time and effort while ensuring a secure and reliable hold. The design incorporates gear tooth geometry and a ratchet pawl’s elastic deformation. This combination converts pulling force into a reliable mechanical lock. It ensures strong, slip-resistant retention. A low-profile head and positive-locking pawl contribute to secure fastening. Serrated straps and a one-way ratcheting pawl are key components of the locking mechanism. The pawl engages precisely cut teeth for high retention. You should note that these ties feature a single-use design. Releasing the pawl can weaken the mechanism, making them unsuitable for reuse.

Optimized Design for Strength and Performance

Xinjing optimizes every aspect of the cable tie’s design for superior strength and performance. You receive high-quality construction, often utilizing premium 304 Stainless Steel. This ensures exceptional durability and longevity. These ties are built to handle strong load support, often up to 200 Lbs. They feature an efficient self-locking head for a secure grip on every application. You can expect a minimum tensile strength of 200 Lbs.

The design also considers environmental conditions. Your cable ties resist corrosion, extreme temperatures, and UV radiation. This maintains performance and integrity in demanding settings. Ease of installation and adjustability are also key features. A smooth, rounded edge design allows for safe handling and quick, efficient bundling. The flexible strap conforms to irregular geometries without cutting into substrates. This enhances performance by allowing versatile application. The strap width and tooth geometry directly influence the holding strength of the cable tie. Xinjing meticulously designs these elements to maximize the tie’s ability to secure heavy cables and wires without risk of slippage or breakage.

Rigorous Quality Assurance for Durable Self-Locking Stainless Steel Cable Ties

You understand that even the best materials and designs require stringent quality control. Xinjing implements rigorous quality assurance protocols. These protocols ensure every self-locking stainless steel cable ties you receive meets the highest standards for durability and performance. We leave nothing to chance.

Multi-Stage Inspection Protocols

Xinjing employs multi-stage inspection protocols throughout the manufacturing process. These checks begin with raw materials and continue through every production phase. This proactive approach identifies potential issues early. You benefit from a product free from common defects. Our inspection teams look for specific flaws:

- Inconsistent thickness

- Rough-cut edges with burrs

- Weak locking mechanisms

They also meticulously check for:

- Weak stamped heads that might bend under torque or release the band

- Undersized or soft locking balls that could deform or pop out under load

- Poor barb engagement where shallow teeth might slip during thermal expansion

Furthermore, inspectors identify:

- Improper forming

- Incomplete locking mechanisms

- Surface irregularities

These detailed inspections guarantee the integrity of each cable tie.

Comprehensive Performance and Stress Testing

You need cable ties that perform under pressure. Xinjing conducts comprehensive performance and stress testing. This ensures your cable ties withstand real-world conditions.

We perform ‘Loop Tensile Strength Testing’. This test measures the mechanical holding force of the cable tie. We stretch it to its limits. The results are then compared against industry standards set by organizations like the National Electrical Manufacturers Association (NEMA) and Underwriter Laboratories (UL).

| Test Parameter | Self-Locking Cable Ties | Reusable Cable Ties |

|---|---|---|

| Loop Tensile Strength | 18 – 250 lbs | 40 – 50 lbs |

Beyond basic performance, Xinjing applies rigorous stress testing methodologies. These tests push the limits of durability:

- Tensile Strength Testing: We verify the cable tie’s load-bearing capacity. We demand third-party test reports from independent labs like SGS, TÜV, and UL. We review batch testing records for consistency. We ensure compliance with recognized standards like IEC 62275 or UL 62275. We recommend a safety factor of at least 2:1.

- Locking Mechanism Reliability Testing: This focuses on the integrity of the self-locking mechanism. We visually inspect the locking ball or barbs for precise machining. We functionally test for smooth operation and consistent resistance. We apply lateral loads to check grip. We use vibration exposure, for example, with a bench vise and reciprocating saw, to simulate real-world conditions. The mechanism must also withstand repeated tightening cycles without degradation.

- Environmental Resistance Verification: This assesses the cable tie’s ability to withstand various environmental stressors. We request ASTM B117 salt spray test data. Quality 316 ties should endure over 1,000 hours without red rust. We verify chloride exposure ratings; 316 grade provides adequate pitting resistance. We confirm the rated temperature range, from -80°C to +538°C. For outdoor use, UV resistance and flame ratings, per UL 62275 or IEC 62275, are also crucial. We ensure compliance with industry certifications like UL Recognition, ISO 10993, AS9100, RoHS, and REACH.

Adherence to International Quality Standards

You can trust Xinjing because we adhere to strict international quality standards. These standards provide a benchmark for excellence. Our products meet critical certifications:

- UL Listed, File No. E530766 Positioning Device 33AS

- UL Standard UL 62275 TYPE 2

- UL Standard UL 62275 TYPE 21S

We also ensure our products are:

- ROHS compliant according to EU directive

These certifications demonstrate our commitment to global quality. You benefit from products that meet the highest benchmarks:

- UL 62275: This North American standard covers critical aspects. It includes tensile strength, temperature ratings, flammability, and UV resistance for cable ties.

- IEC 62275: This international standard provides global consistency for cable ties, mounting bases, and fixing devices.

- ISO 9001: This certification for manufacturers indicates a commitment to quality management systems, customer satisfaction, and continuous improvement. It ensures high-quality products.

- RoHS (Restriction of Hazardous Substances): This regulation limits the use of harmful materials in cable ties.

- REACH (Registration, Evaluation, Authorization and Restriction of Chemicals): This regulation also restricts the use of hazardous chemicals in cable ties. It aligns with environmental considerations.

Additional certifications further validate our quality:

- UL: Underwriters Laboratories certification.

- CSA: Canadian Standards Association certification.

- GL: Germanischer Lloyd certification.

- CE: Conformité Européenne marking.

- CQC: China Quality Certification.

You receive products with top quality standards. UL Certification ensures cable ties endure temperature changes, flammability issues, and sustained pressure. This makes them safe for electrical and automotive uses. CE Marking indicates cable ties meet European safety, health, and environmental protection requirements. This facilitates international market access. ISO Certification signifies a standardized, systematic, scientific, and international quality management system. ISO-certified ties undergo rigorous testing. This guarantees reliability and durability. It makes them ideal for large-scale and international projects.

Xinjing’s comprehensive approach ensures unparalleled durability in every self-locking stainless steel cable ties you receive. We combine superior materials, precise design, and stringent quality control, cumulatively delivering exceptional performance. You can trust Xinjing’s promise of reliable, long-lasting self-locking stainless steel cable ties for your most demanding applications.

FAQ

What makes Xinjing’s self-locking cable ties so durable?

You benefit from high-grade stainless steel, like 304 and 316. Advanced material processing and corrosion engineering ensure exceptional strength and longevity for your applications.

Can these cable ties withstand extreme environmental conditions?

Yes, you can rely on them. Xinjing’s ties resist corrosion, extreme temperatures (from -80°C to +538°C), and UV radiation. They maintain integrity in demanding environments.

Are Xinjing’s self-locking stainless steel cable ties reusable?

No, you should not reuse them. The engineered self-locking mechanism provides a permanent, secure hold. Releasing it can weaken the tie, compromising its reliability.

Post time: Nov-27-2025