Stainless steel cable ties offer robust solutions for securing materials across various industries. Approximately 45% of their usage is in electrical and construction applications, highlighting their importance. Their resistance to corrosion, UV degradation, and extreme temperatures makes them ideal for harsh environments. Selecting and installing these ties correctly enhances your efficiency and safety.

Key Takeaways

- Stainless steel cable ties are durable and resistant to corrosion, making them ideal for harsh environments in various industries.

- Choosing the right type and size of cable tie enhances safety and efficiency in your operations, especially in construction and electrical applications.

- Proper installation techniques, such as using the right tools and maintaining correct tension, ensure the effectiveness and longevity of stainless steel cable ties.

Types of Stainless Steel Cable Ties

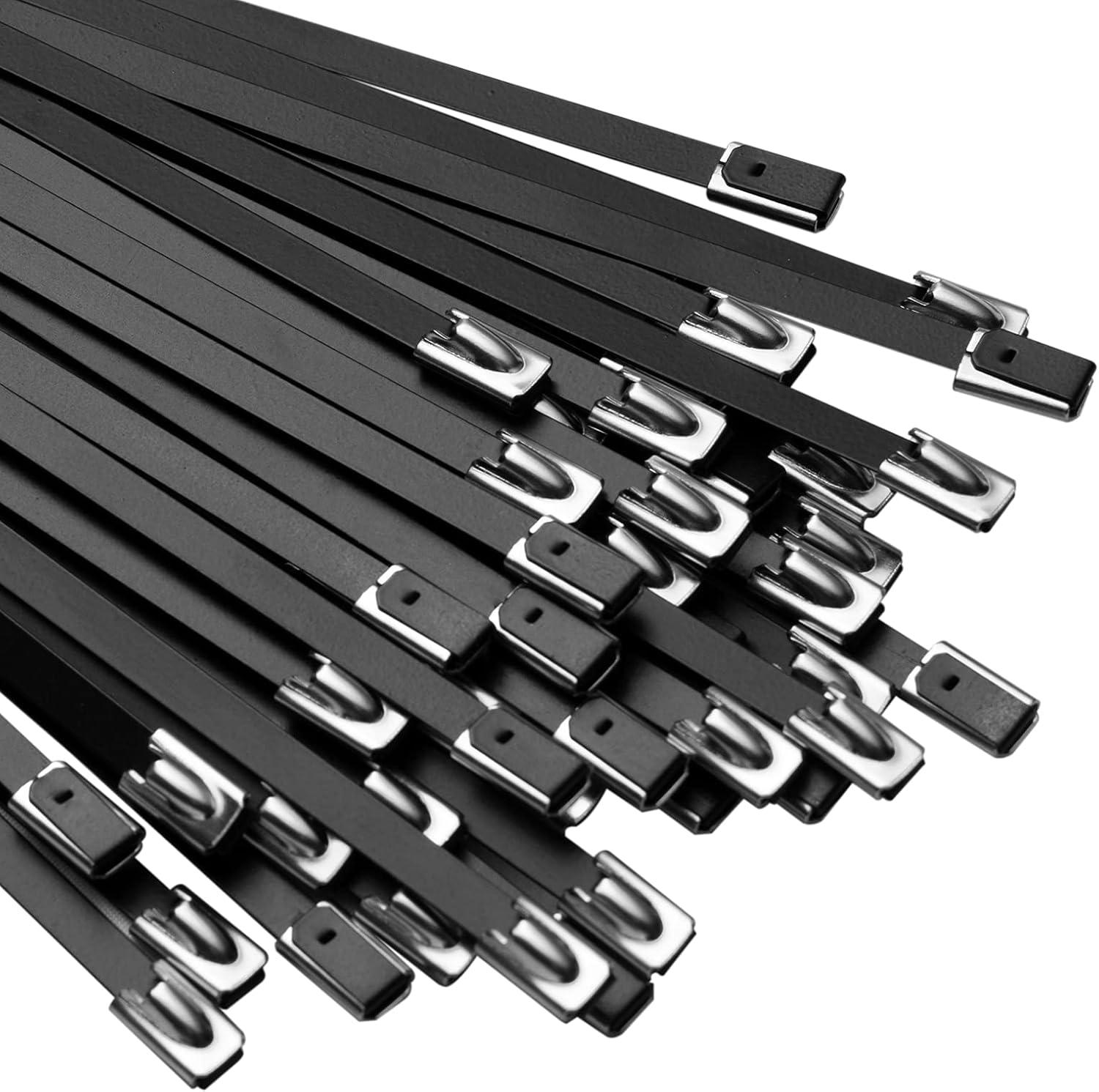

When selecting stainless steel cable ties, you will find several types tailored for specific applications. Understanding these types helps you choose the right one for your needs. Here are some common types:

- Roller Ball: This type features an internal locking ball within the head. It enhances the locking mechanism, allowing for secure cinching. You can rely on roller ball ties for applications requiring a strong hold.

- Ladder: Ladder cable ties are designed for specific applications. They provide unique advantages in certain environments, such as those requiring flexibility and strength.

In addition to these types, you can also find various coatings and finishes that enhance performance:

- Coated Stainless Steel Cable Ties: These ties come with a protective layer, which reduces the risk of corrosion and enhances user safety. The coating also prevents cuts and damage to the cables being tied.

- Uncoated Stainless Steel Cable Ties: These are straightforward and offer high tensile strength. They are ideal for applications where exposure to harsh conditions is minimal.

The tensile strength of stainless steel cable ties varies based on their size and type. Here’s a quick overview of the tensile strength for different sizes:

| Size (inches) | Minimum Loop Tensile Strength (lbs) | Maximum Cable Tie Bundle Diameter (inches) |

|---|---|---|

| 7.913 x 0.18 | 100 | 2.008 |

| 39.291 x 0.18 | 100 | 11.969 |

| 20.512 x 0.31 | 250 | 5.984 |

| 32.992 x 0.31 | 250 | 10 |

| 39.291 x 0.31 | 250 | 11.969 |

You can see that the tensile strength can reach up to 250 lbs, making these ties suitable for demanding applications.

Furthermore, the corrosion resistance levels differ among various grades of stainless steel cable ties. For instance:

- 316 Stainless Steel: This grade excels in environments with high salt, chlorine, or harsh chemicals. It ensures long-term reliability in aggressive settings.

- 304 Stainless Steel: This grade is suitable for less aggressive environments. It provides a durable solution while resisting moisture and oxidation.

By understanding the types and features of stainless steel cable ties, you can make informed decisions that enhance safety and efficiency in your operations.

Applications of Stainless Steel Cable Ties

Stainless steel cable ties serve a wide range of applications across various industries. Their durability and resistance to harsh conditions make them a preferred choice for many professionals. Here are some key sectors where you can effectively utilize these ties:

| Sector | Application Description |

|---|---|

| Construction | Use stainless steel cable ties to secure and bundle materials on construction sites. They withstand heavy loads and harsh weather conditions. |

| Food & Beverage Processing | Ensure hygiene and safety in food handling and processing. These ties help maintain cleanliness and prevent contamination. |

| Manufacturing | Provide reliable cable management in production environments. Their strength supports the organization of complex machinery. |

| Mining | Withstand harsh conditions in mining operations. They secure cables and components in rugged environments. |

| Telecommunications | Essential for organizing and securing network cables. Their durability ensures long-lasting performance in critical systems. |

| Energy | Used in various energy production and distribution applications. They help maintain safety and efficiency in power plants. |

| Transportation | Secure cables and components in vehicles and transport systems. Their reliability enhances safety in transportation infrastructure. |

| Marine | Ideal for use in marine environments due to corrosion resistance. They protect equipment from seawater and strong winds. |

In the oil and gas industry, stainless steel cable ties play a crucial role. You can use them to:

- Secure cables and wires in drilling rigs.

- Employ them in pipelines and refineries.

- Utilize their durability in manufacturing heavy machinery and equipment.

In the marine industry, these ties excel in withstanding harsh elements. They ensure the integrity of equipment and structures in offshore oil and gas sectors. Here are some specific applications:

- Secure various accessories on ships, preventing them from becoming loose during navigation.

- Reinforce accessory structures against wind and rain, ensuring safe navigation.

- Protect cables and pipelines on drilling platforms from corrosion and damage.

Stainless steel cable ties also contribute significantly to safety in electrical installations. Their features provide numerous benefits:

| Feature | Benefit |

|---|---|

| High Temperature Resistance | Ensures stability of cables in extreme temperatures, preventing loosening and potential hazards. |

| Corrosion Resistance | Protects against environmental factors that could compromise cable integrity. |

| Secure Locking Mechanism | Prevents loosening during use, reducing risks of electrical failures or fire spread. |

These ties maintain their integrity in high-temperature environments, unlike traditional nylon ties that can melt. They do not release harmful gases when exposed to heat, reducing fire risks. Their self-locking mechanism ensures cables remain securely bundled, preventing accidents.

In transportation infrastructure projects, stainless steel cable ties offer several advantages:

| Advantage | Description |

|---|---|

| Better safety | They do not rust, preventing safety hazards associated with rusty bolts that can cause road signs to fall. |

| Standardization and aesthetics | Provide a uniform appearance and reduce the need for multiple fixing methods, aligning with urban construction standards. |

| Reduce daily workload | Once installed, they do not require frequent checks for rust, thus minimizing maintenance efforts during adverse weather conditions. |

| Better long-term economic benefits | Although the initial cost is higher, they offer permanent benefits that lead to cost savings over time by reducing the need for inspections and replacements. |

By understanding these applications, you can leverage stainless steel cable ties to enhance safety, efficiency, and reliability in your operations.

Installation Techniques for Stainless Steel Cable Ties

Installing stainless steel cable ties requires specific techniques to ensure maximum security and reliability. Follow these steps for effective installation:

- Determine the Size: Choose the appropriate size of the stainless steel cable tie for your application. This ensures a secure fit.

- Thread the Tie: Insert the tail of the cable tie into the head, ensuring the teeth face inward. This positioning allows for a secure grip.

- Wrap and Secure: Place the cable tie around the items you want to secure. Pull the tail through the head until it is snug.

- Tighten: Use pliers or a cable tie gun to tighten the cable tie until it is secure. This step is crucial for maintaining the integrity of the connection.

- Trim Excess: Use wire cutters to trim the excess tail of the cable tie. Ensure you leave enough length to maintain the locking mechanism’s functionality.

Tip: Always check the connection by gently pulling on the cable tie. It should remain firmly in place. If it loosens, repeat the process with a new tie.

Unlike nylon cable ties, stainless steel cable ties require special tools for installation. Here’s a comparison of the installation features:

| Feature | Nylon Cable Ties | Stainless Steel Cable Ties |

|---|---|---|

| Installation Complexity | Easy to install manually | Requires special tools (cable tie guns) |

| Tools Required | None | Cable tie guns or pliers |

| Maintenance | Regular inspections needed | Low maintenance, good wear resistance |

| Durability | Weaker in harsh environments | High strength and corrosion resistance |

Using the right tools, such as cable tie tensioning tools and cable cutters, enhances the installation process. These tools ensure consistent tension and clean cuts, contributing to the overall effectiveness of your installation.

Common Mistakes with Stainless Steel Cable Ties

Using stainless steel cable ties effectively requires attention to detail. Many users make common mistakes that can compromise performance and safety. Here are some pitfalls to avoid:

- Choosing the Wrong Material: Selecting inappropriate materials can lead to degradation in outdoor conditions. Always opt for high-quality stainless steel grades like 304 or 316, which resist rust and corrosion.

- Neglecting Proper Tension: Incorrect tension can cause cable ties to loosen or damage cables. Over-tightening can lead to breakage or deformation, while under-tightening results in a loose hold that may not be effective.

- Ignoring UV Protection: Prolonged UV exposure can deteriorate cable ties, even if they are weather-resistant. Ensure you choose ties designed for outdoor use to maintain their integrity.

- Forgetting about Abrasion: Rubbing against rough surfaces can wear out cable ties prematurely. Use mounts and anchors for stability when securing bundles to prevent unnecessary wear.

- Skimping on Quality: Using low-quality ties can result in failure under tough outdoor conditions. Invest in premium stainless steel ties to ensure durability and reliability.

To enhance your installation process, consider using a calibrated tensioning tool. This tool helps maintain the right balance of tension, preventing damage to cables and ensuring a secure hold. By avoiding these common mistakes, you can maximize the effectiveness of stainless steel cable ties in your operations.

Proper usage of stainless steel cable ties can significantly improve your operational efficiency. These ties can last 8 to 10 years under tough conditions, while plastic alternatives typically need replacement every 18 to 24 months. By selecting the right type and following correct installation techniques, you enhance workplace safety. Awareness of common mistakes can prevent costly errors, ensuring your projects run smoothly and securely.

Tip: Regularly inspect your ties for damage to maintain their effectiveness.

FAQ

What are the benefits of using stainless steel cable ties?

Stainless steel cable ties offer durability, corrosion resistance, and high tensile strength, making them ideal for harsh environments.

How do I choose the right size of cable tie?

Select a cable tie based on the bundle diameter and the required tensile strength for your specific application.

Can I reuse stainless steel cable ties?

Yes, stainless steel cable ties are reusable. Their durability allows for adjustments without compromising their integrity.

Post time: Sep-05-2025