You need fasteners that excel in tough environments. Self-locking stainless steel cable ties offer unparalleled durability. They provide reliability in extreme automotive conditions. You make a smart choice using them. Secure exhaust components and sensitive sensors. This ensures lasting car performance.

Key Takeaways

- Self-locking stainless steel cable ties are strong. They work well in cars. They handle heat, vibration, and rust better than plastic ties.

- These ties keep car parts safe. They secure exhaust systems and wires. This helps your car run well and last longer.

- Using these ties saves money. They last a long time. You will not need to replace them often.

The Harsh Reality: Why Standard Fasteners Fail in Automotive Applications

You demand reliable performance from your vehicle. However, standard fasteners often fall short in the challenging automotive environment. You face unique stressors that quickly degrade conventional solutions.

Extreme Temperatures Under the Hood

Your car’s engine compartment generates intense heat. These extreme temperatures severely test fastener integrity. You see significant temperature variations depending on your vehicle type.

| Car Type | Temperature Range |

|---|---|

| Modified Car (GSR) | 260°F – 285°F |

| Stock Car (91 teg) | 85°F – 115°F |

You need fasteners that withstand these conditions without softening or becoming brittle.

Constant Vibration and Movement Stress

Your vehicle experiences constant vibration and movement. This dynamic loading places immense stress on fasteners. Even high-quality, well-designed fasteners are susceptible to failure due to vibration. Bolts, nuts, and screws are particularly vulnerable. Slight vibrations over extended periods can lead to their eventual failure, regardless of how tightly you fasten them.

- Loosening due to dynamic loading: Off-the-shelf fasteners loosen under dynamic loading conditions, especially with extreme excitation.

- Fastener relaxation: This gradual process goes unnoticed. It leads to catastrophic failure if you do not identify it during maintenance.

- Resonance-induced unthreading: Vibration phenomena like resonance cause fasteners to loosen. For instance, a test on an automotive winch mount bracket showed resonance in the 51-54 Hz range. This introduced significant cross-axis vibration that unthreaded the nuts.

Corrosive Exposure to Road Elements

You expose your vehicle to harsh road elements. Moisture, salt, chemicals, and debris constantly attack undercarriage components. These corrosive agents accelerate fastener degradation. You need materials that resist rust and chemical breakdown to maintain structural integrity.

Limitations of Plastic and Traditional Metal Ties

You often find plastic and traditional metal ties in automotive applications. However, they have significant limitations. Standard nylon cable ties are typically rated for temperatures between -40°C and 85°C. In automotive engine compartments or near other heat sources, temperatures exceed this range. This causes ties to soften, deform, or melt. Conversely, in freezing conditions, these ties become brittle and snap.

| Application Type | Recommended Tensile Strength | Impact of Insufficient Strength |

|---|---|---|

| Light-duty automotive bundling | 30 lbs | Equipment damage, safety risks |

| Heavy automotive parts | 120 lbs | Equipment damage, safety risks |

| Factors Affecting Strength | Description | |

| Material Composition | Influences strength, flexibility, and resistance to external factors | |

| Environmental Conditions | High temperatures, humidity, and harsh chemicals weaken ties | |

| Installation Techniques | Over-tightening reduces flexibility and increases stress, leading to failure |

You need a solution that overcomes these inherent weaknesses.

Unlocking Durability: The Superiority of Self-Locking Stainless Steel Cable Ties

You need fasteners that perform reliably in your vehicle. Self-locking stainless steel cable ties offer a superior solution. They overcome the limitations of standard fasteners. You gain unmatched durability and performance.

High-Grade Stainless Steel Material Advantages

You benefit from the inherent strength of stainless steel. This material provides exceptional resistance to the harsh automotive environment. It withstands extreme temperatures and corrosive elements. You find specific grades commonly used for automotive applications.

- 304 stainless steel cable ties are used in the automotive industry.

- 316 stainless steel cable ties are used in the automotive industry.

These high-grade alloys ensure your fasteners remain strong and intact. They do not degrade under stress.

Secure Self-Locking Mechanism Benefits

You rely on a secure connection. The self-locking mechanism in these ties provides exactly that. It creates a permanent, non-releasable hold. Once you tighten the tie, it locks firmly in place. This prevents loosening due to vibration or movement. You avoid the common failure points of traditional fasteners. This secure design ensures components stay exactly where you place them.

Exceptional Tensile Strength for Automotive Use

You require fasteners that can handle significant loads. Self-locking stainless steel cable ties offer impressive tensile strength. This strength ensures they hold heavy components securely. You can trust them to withstand dynamic forces.

| Length | Min. Tensile Strength |

|---|---|

| 5.0″ | 200 lbs |

| 8.0″ | 200 lbs |

| 27″ | 200 Lbs |

| 27″ | 485 Lbs |

| 33″ | 200 Lbs |

| 8″ | 350 Lbs |

| 11″ | 350 Lbs |

| 15″ | 350 Lbs |

You can find heavy-duty stainless steel zip ties with up to 485 Lbs tensile strength. This robust capability makes them ideal for critical automotive applications.

Resistance to UV and Chemical Degradation

You expose your vehicle to various environmental factors. Sunlight and chemicals can quickly degrade many materials. Stainless steel cable ties resist these damaging elements. They do not become brittle from UV exposure. They also withstand contact with oils, fuels, and other automotive fluids. Secure™ Plastic Coated 316 Stainless Steel cable ties provide durable, UV-resistant solutions. This makes them ideal for outdoor and solar installations, and equally effective in your car. You ensure long-term integrity for your vehicle’s components.

Critical Applications: Where Self-Locking Stainless Steel Cable Ties Excel

You demand peak performance from your vehicle. This requires reliable components, especially in critical areas. Self-locking stainless steel cable ties provide superior solutions for these demanding applications. They ensure your vehicle operates safely and efficiently.

Securing Exhaust System Components

Your exhaust system endures extreme conditions. It faces intense heat, constant vibration, and corrosive elements. Standard fasteners often fail under this stress. You need a solution that maintains integrity. Self-locking stainless steel cable ties offer exceptional heat resistance. They withstand the high temperatures generated by exhaust gases. Their robust construction also resists vibration-induced loosening. This prevents components from rattling or detaching. You ensure your exhaust system remains securely in place. This reduces noise and prevents potential damage.

Protecting Sensitive Sensor Wiring

Your vehicle relies on numerous sensors for optimal operation. These sensors provide vital data to your car’s computer. Their wiring is often delicate and exposed to harsh environments. You must protect these critical connections. Self-locking stainless steel cable ties excel at this task. They secure wiring away from heat sources and moving parts. This prevents abrasion and short circuits. You can use them to protect:

- Securing thermostat wires

- Control cables

- Sensor leads

This protection ensures accurate data transmission. It helps your engine run smoothly and efficiently.

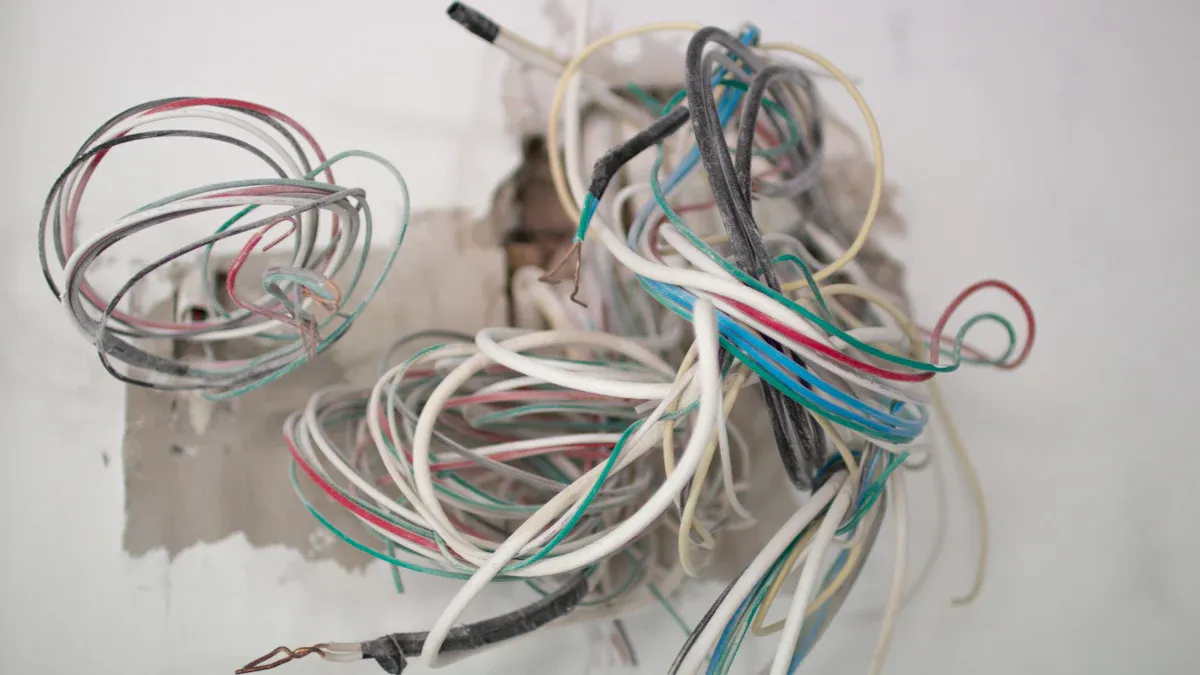

Organizing Under-the-Hood Cable Routing

A well-organized engine bay is crucial for performance and maintenance. Loose cables can chafe, melt, or interfere with moving parts. You need a reliable method to manage wiring. Self-locking stainless steel cable ties provide an ideal solution. They bundle cables neatly and securely. This improves airflow and reduces the risk of electrical issues. You also make future diagnostics and repairs much easier. A tidy engine compartment reflects a well-maintained vehicle.

Fastening Brake and Fuel Lines Safely

Brake and fuel lines are vital safety components. Any compromise to these lines can lead to catastrophic failure. You must ensure their secure fastening. These lines are often exposed to road debris, heat, and vibration. Self-locking stainless steel cable ties offer unparalleled security for these applications. Their high tensile strength prevents movement. Their corrosion resistance protects against leaks caused by environmental damage. You gain peace of mind knowing these critical systems are safely secured. This contributes directly to your vehicle’s overall reliability and safety.

Installation and Longevity: Maximizing Your Investment with Self-Locking Stainless Steel Cable Ties

You make a smart choice when you invest in high-quality fasteners. Self-locking stainless steel cable ties offer long-term value. They provide superior performance and durability for your vehicle.

Simple and Secure Installation Practices

You will find installing these ties straightforward. Their one-piece design simplifies the process. You simply thread the strap through the head and pull it tight. The self-locking mechanism engages instantly. This creates a permanent, secure hold. You do not need special tools for most applications. This ease of installation saves you time and effort.

Contribution to Reduced Maintenance Needs

You reduce your vehicle’s maintenance requirements significantly. These durable ties resist extreme conditions. They do not corrode, melt, or become brittle. This means components stay secured longer. You avoid frequent re-fastening or replacement of failed ties. This reliability translates directly into less time spent on repairs.

Long-Term Cost-Effectiveness Benefits

You realize substantial savings over time. While the initial cost might be higher than plastic ties, their longevity pays off. You eliminate the need for repeated purchases and installations. This reduces labor costs and material waste. Your investment in self-locking stainless steel cable ties prevents costly damage from unsecured components.

Enhancing Overall Vehicle Reliability

You improve your vehicle’s overall dependability. Securely fastened components perform consistently. This prevents unexpected failures or malfunctions. Your engine, exhaust, and wiring systems operate as intended. This enhanced reliability gives you peace of mind on the road.

Material Matters: Types of Stainless Steel for Automotive Cable Ties

You understand the importance of choosing the right materials for your vehicle. The type of stainless steel in your cable ties directly impacts their performance and longevity. You need specific alloys to withstand the harsh automotive environment.

Understanding 304 and 316 Stainless Steel

You often encounter two primary types of stainless steel in automotive applications: 304 and 316. Both offer excellent properties, but they have key differences.

- 304 Stainless Steel: You find this grade widely used. It provides good corrosion resistance and strength. It contains chromium and nickel. This composition makes it suitable for many general automotive uses.

- 316 Stainless Steel: This grade includes molybdenum. Molybdenum significantly enhances corrosion resistance. It performs exceptionally well in environments with chlorides, like road salt. You choose 316 for more extreme conditions.

Benefits of High-Grade Alloys in Harsh Environments

You gain significant advantages by selecting high-grade stainless steel alloys. These materials offer superior performance where standard metals fail. They maintain their structural integrity under constant stress. You benefit from their inherent strength and durability. This ensures your components remain secure, even in demanding situations.

Corrosion Resistance and Heat Tolerance

You need fasteners that resist both rust and high temperatures. Stainless steel excels in these areas.

Tip: 316 stainless steel offers superior resistance to pitting and crevice corrosion, especially in environments exposed to salt or chemicals.

You can trust these ties to perform near hot engine parts or in areas exposed to road spray. They do not degrade from heat or corrosive agents. This ensures a long-lasting, reliable hold for your critical automotive components.

Beyond the Basics: Advanced Features of Self-Locking Stainless Steel Cable Ties

You look for more than just basic functionality in your automotive fasteners. Self-locking stainless steel cable ties offer advanced features. These attributes enhance safety, efficiency, and reliability.

Non-Toxic and Flame Retardant Properties

You prioritize safety in your vehicle. Self-locking stainless steel cable ties offer non-toxic and flame-retardant properties. This is crucial for automotive applications. In the event of a fire, these ties do not release harmful fumes. They also resist ignition. This feature adds an extra layer of protection for your vehicle’s occupants and components. You ensure a safer environment under the hood.

Low-Profile, Self-Locking Ball Bearing Head Design

You benefit from intelligent design. The low-profile head of these ties prevents snags. This is especially important when you navigate uneven surfaces. It also helps when threading through confined spaces like bulkheads. This design makes installation easier. It reduces the risk of damage or obstruction. The self-locking ball bearing mechanism ensures a secure and immediate hold. It wedges the tie’s tail in place. This robust locking action resists loosening. Vibrations or thermal cycling will not compromise the hold. This enhances the long-term performance and reliability of the cable tie. You gain confidence in your connections.

One-Piece Construction for Fast Installation

You value efficiency in every task. The one-piece construction of these self-locking stainless steel cable ties simplifies installation significantly. You do not need to manage multiple components or complex tools. This integrated design allows for quick and easy application. You simply thread the strap and pull it tight. This saves valuable time during assembly or maintenance. This streamlined process contributes to overall operational efficiency. You complete tasks faster and more reliably.

The Economic Advantage: Why Self-Locking Stainless Steel Cable Ties are a Smart Investment

You constantly seek ways to optimize your vehicle’s performance and minimize expenses. Investing in high-quality fasteners offers significant economic advantages. You make a wise decision choosing durable solutions.

Initial Cost vs. Long-Term Savings

You might notice plastic (nylon) cable ties are much cheaper initially. They offer a budget-friendly option for immediate purchase. However, stainless steel ties have a higher upfront price. Their reusability and superior durability lead to lower overall costs over time. You avoid frequent replacements. This reduces material expenses and labor.

Reducing Repair and Replacement Frequencies

You benefit from the exceptional resilience of these ties. They withstand extreme temperatures, vibrations, and corrosive elements. This durability means components remain securely fastened for extended periods. You experience fewer failures. This reduces the need for frequent repairs and replacements. Your vehicle spends less time in the shop. This saves you money on maintenance and labor costs.

Impact on Vehicle Resale Value

You understand that a well-maintained vehicle holds its value better. Durable fasteners contribute to this. They ensure critical components remain secure and functional. This prevents damage and premature wear. A vehicle with reliable, long-lasting parts presents better to potential buyers. You enhance your vehicle’s perceived quality and actual longevity. This positively impacts its resale value.

You make a strategic decision when you embrace self-locking stainless steel cable ties. They offer superior durability and reliability for any automotive application. Their robust design and material composition directly address harsh automotive environment challenges. These ties ensure lasting car performance and give you peace of mind.

FAQ

What makes stainless steel cable ties better than plastic ones for cars?

You gain superior resistance to extreme temperatures, corrosion, and vibration. Stainless steel ensures lasting security where plastic fails.

How does the self-locking mechanism benefit my vehicle?

The self-locking design creates a permanent, secure hold. It prevents loosening from constant vibration, keeping your components safely in place.

Which type of stainless steel should I choose for automotive applications?

You typically use 304 stainless steel for general needs. For harsh, corrosive environments, like road salt exposure, you choose 316 stainless steel.

Post time: Dec-05-2025