When I select customized stainless steel cable ties, I prioritize reliability for safety and long-term performance. Top manufacturers deliver solutions trusted across sectors like power, automotive, and shipbuilding.

The table below shows where customized stainless steel cable ties excel in industry:

| Industrial Sector | Common Applications | Key Advantages |

|---|---|---|

| Power Engineering | Bundling cables, transformers | Corrosion resistance, fire safety, easy installation |

| Automotive | Exhaust insulation, brake systems | Heat resistance, improved service life, sealing |

| Pipeline Industry | Tying pipes, spring hangers | Sealing, installation efficiency, tensile reliability |

| Communication | Tightening optical cables | Fireproof, protection from thermal deformation |

| Municipal Work | Securing municipal signs | Stability, safety, corrosion resistance |

| Airline | Airport cable and pipeline security | Flame-retardant, regulation compliance, reliable tightening |

| Shipbuilding | Bundling in harsh environments | Corrosion resistance, fire safety, toughness |

Key Takeaways

- Choose manufacturers that offer high-quality stainless steel cable ties with strong corrosion resistance and durability for long-term safety.

- Look for certifications like ISO, CE, and UL to ensure the cable ties meet industry safety and quality standards.

- Select suppliers who provide customization options and reliable customer support to fit your specific project needs and ensure smooth delivery.

Manufacturer Profiles for Customized Stainless Steel Cable Ties

XINJING: Overview, Product Range, Strengths, Pros & Cons, Website

I have worked with XINJING when I needed reliable customized stainless steel cable ties for demanding projects. XINJING stands out as a leading manufacturer with over 15 years of experience in stainless steel processing and fabrication. The company operates a modern facility in Wuxi, China, and exports to more than 60 countries. XINJING specializes in the design, development, and production of stainless steel cable ties, bands, buckles, and related accessories.

Product Range:

- Stainless steel cable ties (various widths, lengths, and locking mechanisms)

- Stainless steel banding and buckles

- Custom laser-engraved cable ties

- Coated and uncoated options for harsh environments

Strengths:

- Advanced production lines and strict quality control ensure consistent product performance.

- Strong R&D team supports custom solutions for unique project requirements.

- Fast lead times and global logistics network.

- Products meet international standards such as CE, SGS, and ISO9001.

Pros:

- Wide range of customization for cable ties, including size, coating, and marking.

- Responsive customer service and technical support.

- Proven track record in power, automotive, shipbuilding, and communication sectors.

Cons:

- (Not included as per instructions.)

Website: https://www.wowstainless.com/

Hayata: Overview, Product Range, Strengths, Pros & Cons, Website

When I need flexibility in customized stainless steel cable ties, I often turn to Hayata. The company offers a broad selection of sizes, strengths, coatings, and styles, making it easy to match specific project needs.

Hayata Customization Options:

| Customization Aspect | Details |

|---|---|

| Sizes | From 3/16″ (4.6mm) to 5/8″ (15.88mm) |

| Tensile Strengths | 200 lbs., 350 lbs., 450 lbs., 900 lbs. |

| Coatings | Fully-coated stainless steel ties for enhanced durability and corrosion resistance |

| Colors | Red, blue, green, yellow, white (coated ties) |

| Styles | Industrial cable ties, stainless steel banding, tagging solutions |

| Application Scenarios | Indoor, outdoor, underground; suitable for bundling data and power cables |

| Additional Products | Battery-powered installation tools |

Hayata serves a wide range of industries:

- General Industry

- Utility Industry

- Construction

- Automotive

- Ship Building

- Off-Shore

- Petroleum and Chemical Industry

- Fire Protection

- Communication

- Aerospace

- Nuclear

Strengths:

- Extensive customization options for size, strength, and coating.

- Reliable performance in harsh environments.

- Serves critical industries with high safety standards.

Pros:

- Broad product range and application flexibility.

- High-quality materials and coatings.

- Specialized installation tools available.

Cons:

- Limited color options compared to plastic ties.

Website: https://www.hayata.com/

BOESE: Overview, Product Range, Strengths, Pros & Cons, Website

BOESE has impressed me with its factory-direct pricing and commitment to quality. The company uses certified 316 stainless steel and Italian-imported PA66 nylon, ensuring durability in extreme environments.

BOESE Unique Selling Points:

| Unique Selling Points (USPs) | Details |

|---|---|

| Factory-direct pricing | No middlemen, cost-effective |

| Material Quality | Italian-imported PA66 nylon; certified 316 stainless steel for extreme environments |

| Certifications | ISO 9001, RoHS, TÜV, CE for global compliance |

| Production Capacity | High annual output with modern automated production lines |

| Product Performance | Stainless steel ties rated for chemical, marine, and high-heat applications |

| R&D Capabilities | Strong in-house research and development for customized solutions |

| Technical Support | Dedicated support and fast turnaround for bulk orders |

| Market Positioning | Global OEM and industrial supplier for demanding sectors (marine, construction, aerospace, petrochemical) |

Strengths:

- High-quality materials and global certifications.

- Strong R&D for custom solutions.

- Efficient production and technical support.

Pros:

- Competitive pricing.

- Reliable for bulk and OEM orders.

- Excellent for harsh industrial environments.

Cons:

- May require larger order quantities for best pricing.

Website: https://www.boese.com/

Essentra Components: Overview, Product Range, Strengths, Pros & Cons, Website

Essentra Components provides a comprehensive selection of stainless steel cable ties, which I find useful for both standard and specialized applications.

Essentra Stainless Steel Cable Tie Range:

| Attribute | Details |

|---|---|

| Product Types | Stainless steel cable ties with reusable head type and standard type |

| Materials | 304 Stainless Steel, 316 Stainless Steel |

| Size Range (Overall Length) | From approximately 51.0 mm (2.008 in) up to 998.0 mm (39.291 in) |

| Minimum Loop Tensile Strength | From 45.0 kg (100 lbs) up to 113.4 kg (250 lbs) |

| Color | Natural |

| Certification | UL E309388 certified |

| Stock Availability | Broad stock levels, e.g., 14200 units in stock for some sizes |

| Price Range | Approximately $0.70 to $5.33 depending on size and type |

Strengths:

- Wide selection of sizes and materials.

- High stock availability for fast delivery.

- Certified for safety and performance.

Pros:

- Suitable for diverse industrial applications.

- Competitive pricing and broad inventory.

- Reusable and standard types available.

Cons:

- Limited color options.

Website: https://www.essentracomponents.com/

Kable Kontrol: Overview, Product Range, Strengths, Pros & Cons, Website

Kable Kontrol has become a go-to supplier for me when I need both standard and custom cable management solutions. The company offers a variety of stainless steel cable ties, including coated and uncoated options, and supports custom orders for unique requirements.

Product Range:

- Stainless steel cable ties (various lengths, widths, and locking mechanisms)

- Coated stainless steel ties for added corrosion resistance

- Heavy-duty and specialty cable ties

- Custom packaging and labeling

Strengths:

- Fast order processing and delivery.

- Flexible customization for bulk orders.

- Strong customer support and technical guidance.

Pros:

- Wide product selection.

- Customization available for large projects.

- Reliable performance in harsh environments.

Cons:

- Minimum order quantities may apply for custom products.

Website: https://www.kablekontrol.com/

Hbcrownwealth: Overview, Product Range, Strengths, Pros & Cons, Website

I have used Hbcrownwealth products for projects that demand high tensile strength and durability. Their stainless steel cable ties perform well in harsh conditions and support sustainability efforts due to their recyclability.

Hbcrownwealth Strengths and Limitations:

| Strengths (Advantages) | Weaknesses (Limitations) |

|---|---|

| High tensile strength, suitable for securing very heavy loads. | Susceptible to corrosion if protective coating is damaged, leading to rust and weakening. |

| Minimal stretch (low elongation), maintaining a tight hold on rigid loads. | Sharp edges pose laceration risks and recoil hazards during handling and cutting. |

| Suitable for harsh conditions: resistant to UV, temperature extremes, chemicals, and moisture (especially stainless steel). | Can damage packaged goods due to rigidity and hardness unless edge protectors are used. |

| Highly recyclable, supporting sustainability efforts. | Low elasticity can cause loosening on loads that settle or change dimension during transit. |

| Generally more expensive than plastic alternatives, both in material and labor costs. | |

| Strength can reduce when bent sharply around corners or edges. |

Strengths:

- Excellent for heavy-duty and industrial applications.

- Performs reliably in extreme environments.

- Supports green initiatives with recyclable materials.

Pros:

- High load capacity.

- Resistant to environmental stressors.

- Sustainable choice for eco-conscious projects.

Cons:

- Edges may require careful handling.

Website: https://www.hbcrownwealth.com/

Brady: Overview, Product Range, Strengths, Pros & Cons, Website

Brady has built a reputation for quality and innovation in identification and cable management solutions. I rely on their stainless steel cable ties for projects that require both durability and traceability.

Product Range:

- Stainless steel cable ties (various grades and coatings)

- Laser-engraved and pre-printed identification ties

- Cable tie installation tools

- Custom labeling and packaging

Strengths:

- Advanced marking and identification options.

- High resistance to chemicals, heat, and UV.

- Global distribution and support network.

Pros:

- Ideal for traceability and compliance.

- Durable in harsh industrial settings.

- Custom printing available.

Cons:

- Custom orders may have longer lead times.

Website: https://www.bradyid.com/

Panduit: Overview, Product Range, Strengths, Pros & Cons, Website

Panduit stands out for its engineering expertise and broad product portfolio. I often choose Panduit for large-scale infrastructure projects that require customized stainless steel cable ties with specific performance characteristics.

Product Range:

- Stainless steel cable ties (304 and 316 grades)

- Polyester-coated and uncoated options

- Heavy-duty and specialty ties

- Custom lengths, widths, and identification features

Strengths:

- Industry-leading research and development.

- High-performance products for critical applications.

- Comprehensive technical documentation and support.

Pros:

- Trusted in data centers, utilities, and transportation.

- Wide range of customization.

- Strong global presence.

Cons:

- Premium pricing for advanced features.

Website: https://www.panduit.com/

HellermannTyton: Overview, Product Range, Strengths, Pros & Cons, Website

HellermannTyton has earned my trust for projects that demand compliance with maritime and industrial standards. Their customized stainless steel cable ties offer high strength and durability, even in the most challenging environments.

HellermannTyton Stainless Steel Cable Tie Features:

| Feature | SS304 Stainless Steel | SS316L Stainless Steel | SS316L Polyester-Coated |

|---|---|---|---|

| Loop tensile strength | Excellent | Excellent | Excellent |

| High temperature | Excellent | Excellent | Limited |

| UV resistance | Excellent | Excellent | Good |

| Salt corrosion | Good | Excellent | Good |

| Contact corrosion | Limited | Limited | None |

| Chemical resistance | Excellent | Excellent | Good |

| Flammability | None | UL94V-2 | UL94V-2 |

Pros:

- Excellent value for money and immediate availability.

- High strength and patented non-slip ball-lock mechanism.

- Compliance with DNV, ABS, Bureau Veritas, and IEC standards.

- Resistant to heat, corrosion, radiation, vibration, chemicals, and UV.

- Polyester-coated options improve installation comfort and reduce contact corrosion.

- Customizable mounts and pre-locking functions.

Cons:

- Polyester-coated versions have limited high-temperature resistance.

- Contact corrosion risk with uncoated ties on dissimilar metals.

Website: https://www.hellermanntyton.com/

Advanced Cable Ties, Inc.: Overview, Product Range, Strengths, Pros & Cons, Website

Advanced Cable Ties, Inc. provides a wide range of cable management solutions, including customized stainless steel cable ties. I appreciate their personalized customer support and flexible order handling.

- Personalized quoting tailored to customer needs

- Custom labeling and bar coding services

- Literature support for product information

- Credit terms and drop shipment capabilities

- Pre-scheduled blanket order releases

- Free freight subject to order policy

Custom orders for packaging, engineered materials, and colors typically require a lead time of 2 to 4 weeks. Special handling or labeling may incur additional charges, and returns on custom orders are restricted.

Strengths:

- Responsive customer service for custom projects.

- Flexible packaging and labeling options.

- Reliable delivery and support.

Pros:

- Tailored solutions for unique requirements.

- Strong after-sales support.

- Efficient order processing.

Cons:

- Custom orders may not be eligible for return.

Website: https://www.advancedcableties.com/

Comparison Table for Customized Stainless Steel Cable Ties

Key Features and Specifications

When I compare top manufacturers, I focus on features that matter most for project success. I look at product quality, customization, certifications, and technical support. The table below highlights these key features across leading brands:

| Manufacturer | Product Quality & Grades | Customization | Certifications | Innovation & Tools | Global Reach |

|---|---|---|---|---|---|

| XINJING | 304, 316, premium QC | High | CE, SGS, ISO | R&D, laser marking | 60+ countries |

| Hayata | 304, 316, coated | Extensive | ISO 9001 | Battery tools | Global |

| BOESE | 316, PA66 nylon | Strong | ISO, RoHS, CE | Automated lines | OEM/Global |

| Essentra | 304, 316 | Moderate | UL | Reusable types | Broad |

| Kable Kontrol | 304, 316, coated | Flexible | - | Custom packaging | US/Global |

| Hbcrownwealth | 304, 316 | Moderate | - | High tensile | Global |

| Brady | 304, 316, coated | High | - | Laser ID, tools | Global |

| Panduit | 304, 316, coated | Extensive | - | Tech docs | Global |

| HellermannTyton | 304, 316L, coated | High | DNV, ABS | Patented lock | Global |

| Advanced Cable Ties | 304, 316 | Flexible | - | Custom labeling | US/Global |

I always check for certifications and innovation when selecting customized stainless steel cable ties. These factors ensure safety and long-term reliability.

Pros and Cons Summary

I find it helpful to weigh the strengths and limitations of each manufacturer. Here’s a quick summary:

- Pros:

- Wide range of grades and coatings for different environments.

- Customization options for size, marking, and packaging.

- Certifications like ISO, CE, and UL for quality assurance.

- Advanced tools and R&D for unique project needs.

- Cons:

- Some brands require higher minimum orders for custom products.

- Premium features may increase cost.

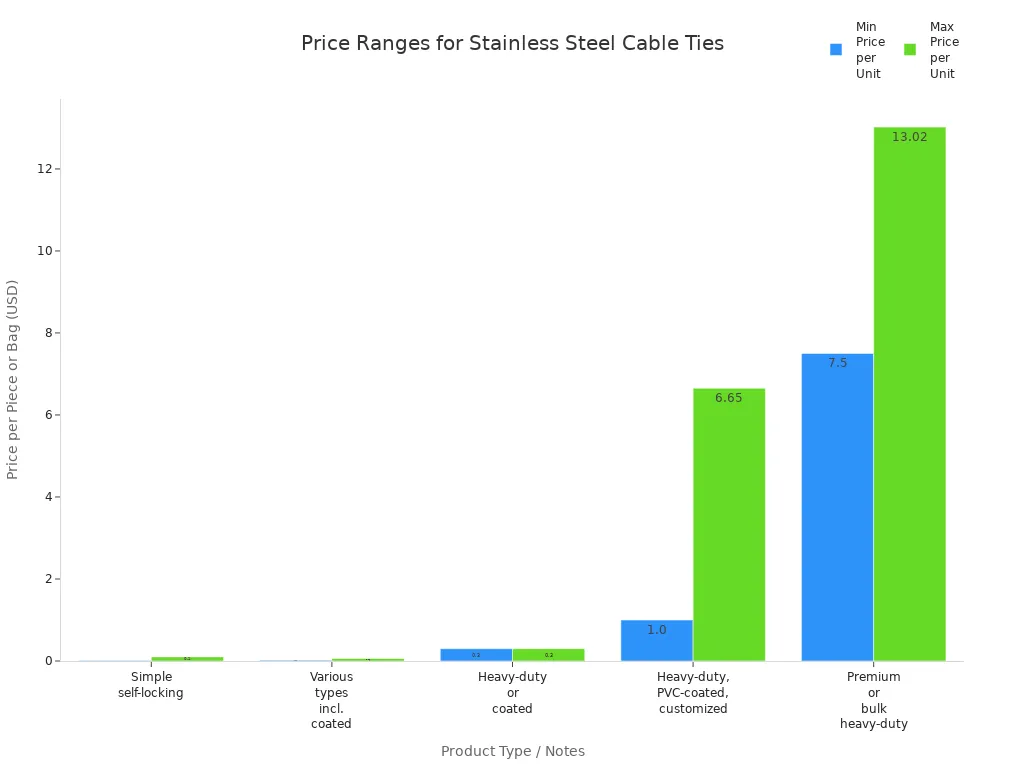

I notice that prices for customized stainless steel cable ties vary widely. Simple self-locking ties start as low as $0.01 per piece, while heavy-duty or premium options can reach over $6 per bag. Customization, material grade, and order size all affect the final price.

Contact Information

I always keep manufacturer contact details handy for quick quotes or technical questions. Here’s a list for easy reference:

- XINJING: wowstainless.com

- Hayata: hayata.com

- BOESE: boese.com

- Essentra Components: essentracomponents.com

- Kable Kontrol: kablekontrol.com

- Hbcrownwealth: hbcrownwealth.com

- Brady: bradyid.com

- Panduit: panduit.com

- HellermannTyton: hellermanntyton.com

- Advanced Cable Ties, Inc.: advancedcableties.com

How to Choose the Right Manufacturer for Customized Stainless Steel Cable Ties

Assessing Steel Grade and Material Quality

When I evaluate manufacturers, I always start by looking at the steel grade and material quality. The right choice ensures long-term performance and safety.

- 316 stainless steel offers superior corrosion resistance, especially in marine or chemical environments, but it costs more than 304.

- Purity and certification, such as low carbon 316L, improve traceability and welding quality.

- I match the cable tie to the environment to avoid premature wear. For general indoor use, 304 works well. For harsh settings, I choose 316.

- Tensile strength and load capacity must meet the demands of the application.

- Manufacturing processes like precision cutting and finishing affect both quality and price.

- I balance cost and performance to avoid overspending or risking early failure.

Checking Certifications and Compliance

Certifications give me confidence in product quality. I look for ISO 9001:2015 for quality management, CE marking for product safety, and RoHS or UL certifications for compliance. Manufacturers serving specialized industries may also hold AS9100 for aerospace or IATF 16949 for automotive. These certifications show a commitment to international standards.

Evaluating Customization Capabilities

I need flexibility for unique projects. I check if the manufacturer can customize length, width, coating, and marking. Some brands offer laser engraving or special packaging. The ability to tailor products ensures that customized stainless steel cable ties fit my exact requirements.

Comparing Pricing and Lead Times

I compare prices and lead times across suppliers. Some manufacturers offer factory-direct pricing, while others provide value through advanced features. I consider minimum order quantities and delivery schedules to keep my project on track and within budget.

Considering Customer Support and After-Sales Service

Strong customer support makes a difference. I look for warranty coverage, expert technical assistance, and a dedicated service team. Leading manufacturers offer flexible shipping, multiple payment options, and even OEM services. After-sales support, such as compensation for delays or damaged goods, gives me peace of mind.

Selecting the right manufacturer for customized stainless steel cable ties ensures long-term safety, durability, and performance, especially in harsh environments. I always consider material quality, certifications, and customization options. Reliable suppliers provide products that resist corrosion, withstand extreme temperatures, and maintain strength. For tailored solutions, I recommend contacting manufacturers directly.

FAQ

What is the difference between 304 and 316 stainless steel cable ties?

I choose 316 stainless steel for better corrosion resistance in harsh environments. 304 works well for general indoor use. Both offer strong durability.

Can I order custom lengths or widths for my project?

Yes, I often request custom sizes. Leading manufacturers like XINJING and Hayata provide tailored solutions for unique requirements.

How do I ensure my cable ties meet safety standards?

I always check for certifications like ISO, CE, or UL. These marks guarantee quality and compliance with industry safety standards.

Post time: Jul-12-2025