You need solutions that endure the toughest conditions, and stainless steel cable ties deliver unmatched performance. Their durability ensures they hold strong under pressure. These ties resist corrosion, making them ideal for extreme environments. Versatility allows you to use them in countless applications, from heavy-duty tasks to long-term projects. They outperform other options every time.

Key Takeaways

- Stainless steel cable ties are strong and last a long time. They work well for tough jobs and places with lots of shaking.

- Picking the right stainless steel, like 304 for normal use or 316 for tough spots, helps them work better and last longer.

- Buying good stainless steel cable ties lowers repair costs later. They stay reliable for years and help save money.

Benefits of Stainless Steel Cable Ties

Exceptional Durability and Strength

You need cable ties that can handle heavy loads without breaking. Stainless steel cable ties offer exceptional strength, making them ideal for demanding applications. Their robust construction allows them to secure large bundles of cables, pipes, or equipment with ease. Unlike plastic ties, they resist stretching and snapping under pressure.

Tip: Use stainless steel cable ties for tasks requiring high tensile strength, such as industrial machinery or construction projects.

Their durability ensures they perform reliably even in environments with constant vibration or mechanical stress. Whether you’re working on a manufacturing floor or an outdoor installation, these ties won’t let you down.

Resistance to Corrosion and Harsh Conditions

Extreme environments demand materials that can withstand harsh conditions. Stainless steel cable ties excel in resisting corrosion caused by moisture, chemicals, and salt exposure. This makes them perfect for marine applications, offshore installations, and areas with high humidity.

You can rely on these ties in environments with fluctuating temperatures or exposure to UV radiation. Their resistance to rust ensures they maintain their integrity over time, even in the most challenging situations.

Note: For environments with high salt content, consider using 316 stainless steel cable ties for enhanced corrosion resistance.

Long-Term Cost Efficiency

Investing in stainless steel cable ties saves you money in the long run. Their durability reduces the need for frequent replacements, lowering maintenance costs. While their upfront cost may be higher than plastic alternatives, their extended lifespan makes them a cost-effective choice.

You also avoid the risks associated with failed ties, such as damaged equipment or downtime. By choosing stainless steel cable ties, you ensure reliable performance and minimize unexpected expenses.

Callout: High-quality stainless steel cable ties offer the best balance between durability and cost efficiency.

Factors to Consider When Choosing Stainless Steel Cable Ties

Material Type: 304 vs. 316 Stainless Steel

Choosing the right material is crucial for performance. Stainless steel cable ties come in two main types: 304 and 316 stainless steel. You should select 304 stainless steel for general applications. It offers excellent strength and corrosion resistance for indoor and light outdoor use.

For harsher environments, 316 stainless steel is the better choice. It contains molybdenum, which enhances its resistance to saltwater, chemicals, and extreme weather. This makes it ideal for marine, offshore, or industrial settings.

Tip: Use 316 stainless steel cable ties for areas with high humidity or salt exposure to ensure long-term reliability.

Appropriate Size and Length

The size and length of the cable ties determine their suitability for your project. You need to measure the diameter of the bundle or object you want to secure. Choose ties that are slightly longer than the circumference to ensure a proper fit.

Cable ties come in various widths, ranging from narrow ties for small bundles to wider ties for heavy-duty applications. Wider ties provide greater tensile strength and stability.

Note: Always check the manufacturer’s specifications for size recommendations based on your application.

Application Type: Indoor vs. Outdoor Use

Consider where you plan to use the cable ties. For indoor applications, standard stainless steel cable ties work well. They resist wear and tear from everyday use.

Outdoor applications require ties that can withstand UV radiation, moisture, and temperature fluctuations. Coated stainless steel cable ties offer added protection against environmental factors.

Callout: Match the cable ties to the environment to avoid premature wear or failure.

Tensile Strength and Weight Capacity

Tensile strength is a key factor when securing heavy loads. You need to check the weight capacity of the cable ties to ensure they can handle the pressure.

For industrial or construction projects, choose ties with high tensile strength ratings. These ties prevent snapping or stretching under heavy loads.

Tip: Look for tensile strength ratings on the packaging to match the ties to your specific needs.

Installation Tools and Methods

Proper installation ensures the ties perform as expected. You can use manual tools like pliers or specialized tensioning tools for a secure fit.

Tensioning tools help you achieve consistent tightness, reducing the risk of over-tightening or under-tightening. They also make installation faster and more efficient.

Note: Invest in quality installation tools to improve accuracy and save time during setup.

Temperature and Environmental Ratings

Temperature and environmental ratings determine how well the cable ties perform under extreme conditions. You need to check the manufacturer’s specifications for temperature limits.

For high-temperature environments, choose ties designed to resist heat without losing strength. In cold climates, select ties that remain flexible and durable.

Callout: Always verify the environmental ratings to ensure the ties meet your project’s requirements.

Tips for Selecting the Best Stainless Steel Cable Ties

Match Cable Ties to Specific Applications

You should always choose cable ties that align with your specific project needs. For heavy-duty tasks like securing industrial equipment, select ties with high tensile strength. For smaller jobs, such as bundling wires, lighter options work better. Matching the tie to the application ensures optimal performance and prevents unnecessary wear or failure.

Tip: Keep a variety of sizes and strengths on hand to handle different tasks efficiently.

Consider Environmental and Weather Conditions

Environmental factors play a critical role in the longevity of your cable ties. For outdoor projects, select ties designed to withstand UV rays, moisture, and temperature fluctuations. In marine or coastal areas, opt for ties with enhanced corrosion resistance, such as those made from 316 stainless steel.

Callout: Using the wrong type of tie in harsh conditions can lead to premature failure.

Balance Quality with Budget Constraints

While high-quality ties may cost more upfront, they often save you money in the long run. Cheaper alternatives may fail under stress, leading to costly repairs or replacements. Evaluate your budget and prioritize durability and reliability over short-term savings.

Look for Coated Options for Added Protection

Coated stainless steel cable ties offer an extra layer of protection against abrasion and environmental damage. These ties are especially useful in applications where the ties may come into contact with delicate surfaces or harsh chemicals.

Note: Coated ties also reduce the risk of injury during installation by covering sharp edges.

Choose Trusted Brands and Certifications

Reputable brands provide consistent quality and performance. Look for certifications that guarantee the ties meet industry standards. This ensures you’re investing in a product that delivers reliable results.

Tip: Research customer reviews and product specifications before making a purchase.

Common Applications of Stainless Steel Cable Ties

Industrial and Manufacturing Uses

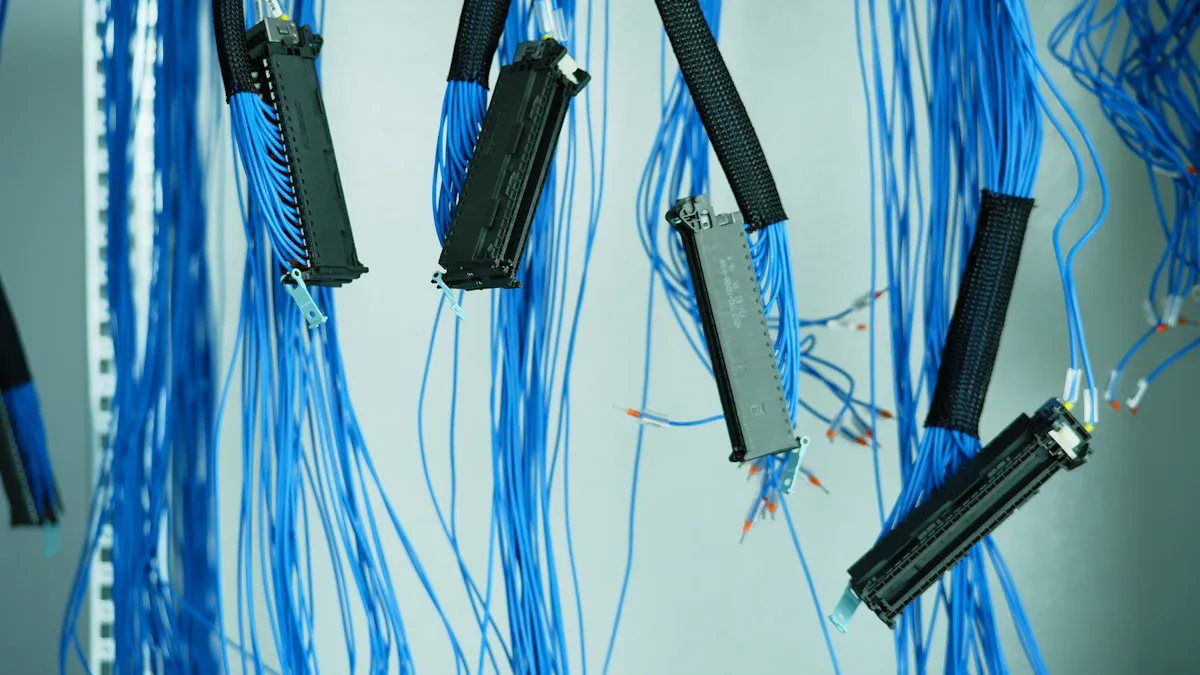

You rely on stainless steel cable ties to secure heavy machinery and equipment in industrial settings. Their strength and durability make them ideal for bundling cables, hoses, and pipes in manufacturing plants. These ties withstand vibrations and mechanical stress, ensuring your installations remain intact during operations.

In production lines, stainless steel cable ties help organize wiring systems, reducing the risk of accidents or downtime. Their resistance to heat and chemicals makes them suitable for environments with high temperatures or exposure to industrial solvents.

Tip: Use stainless steel cable ties to improve safety and efficiency in manufacturing processes.

Marine and Offshore Applications

Saltwater environments demand materials that resist corrosion, and stainless steel cable ties excel in these conditions. You use them to secure cables and equipment on ships, docks, and offshore platforms. Their ability to withstand salt exposure and humidity ensures long-term reliability.

Marine applications often involve fluctuating temperatures and UV radiation. Stainless steel cable ties maintain their integrity under these challenges, making them a dependable choice for coastal and offshore projects.

Callout: Opt for 316 stainless steel cable ties for enhanced corrosion resistance in marine environments.

Construction and Infrastructure Projects

Construction sites require materials that can handle heavy loads and harsh conditions. Stainless steel cable ties provide the strength you need to secure scaffolding, pipes, and electrical wiring. Their resistance to weather and UV radiation makes them perfect for outdoor installations.

You can use these ties to organize cables in infrastructure projects like bridges, tunnels, and railways. Their durability ensures they perform reliably even in demanding environments.

Note: Stainless steel cable ties reduce maintenance costs by lasting longer in construction applications.

Automotive and Aerospace Industries

In automotive and aerospace industries, precision and reliability are critical. Stainless steel cable ties help you secure wiring systems, fuel lines, and hydraulic hoses. Their resistance to heat and vibration ensures they perform well in engines and aircraft components.

You also use these ties to organize cables in vehicles and aircraft, improving safety and efficiency. Their ability to withstand extreme temperatures makes them suitable for high-performance applications.

Tip: Choose stainless steel cable ties for tasks requiring high tensile strength and temperature resistance.

Stainless steel cable ties provide unmatched durability and versatility, making them the ideal choice for 2025. You can ensure optimal performance by selecting the right material, size, and environmental rating. Investing in high-quality options reduces maintenance costs and guarantees long-term reliability, whether for industrial, marine, or construction applications.

FAQ

1. Can stainless steel cable ties be reused?

No, stainless steel cable ties are designed for single-use applications. Cutting them during removal ensures safety and prevents damage.

2. How do you install stainless steel cable ties securely?

Use a tensioning tool for consistent tightness. Avoid over-tightening to prevent damage to the secured items.

3. Are coated stainless steel cable ties better for delicate surfaces?

Yes, coated ties reduce abrasion and protect sensitive surfaces. They also improve safety during installation by covering sharp edges.

Post time: Jun-04-2025