You need reliable fastening in tough conditions. Self-locking stainless steel cable ties are essential in harsh environments. They offer unparalleled durability. You get resistance to extreme conditions. Their secure fastening capabilities surpass conventional ties. Stainless Steel Cable Ties provide a superior solution for your demanding needs.

Key Takeaways

- Self-locking stainless steel cable ties are very strong. They work well in tough places where other ties break.

- These ties resist rust, extreme heat, and cold. They also resist damage from chemicals and sunlight.

- The special lock on these ties keeps them tight. This makes them safe for many important jobs.

Why Traditional Fasteners Fail Where Self-Locking Stainless Steel Cable Ties Excel

You need fastening solutions that perform reliably. Traditional fasteners often fall short in demanding conditions. Self-locking stainless steel cable ties offer superior performance. They overcome the limitations of conventional options.

Limitations of Plastic and Other Metal Ties

Plastic cable ties, while common, present significant weaknesses in harsh environments. High temperatures severely compromise their integrity. Prolonged heat exposure causes plastic to soften. This reduces its strength. The molecular structure loosens. Long-term high temperatures also lead to aging and embrittlement. Thermal oxidation and chain scission damage the internal structure. This results in irreversible hardening. Plasticizers can volatilize. You will see color changes, like yellowing and fading, under extended heat and UV exposure.

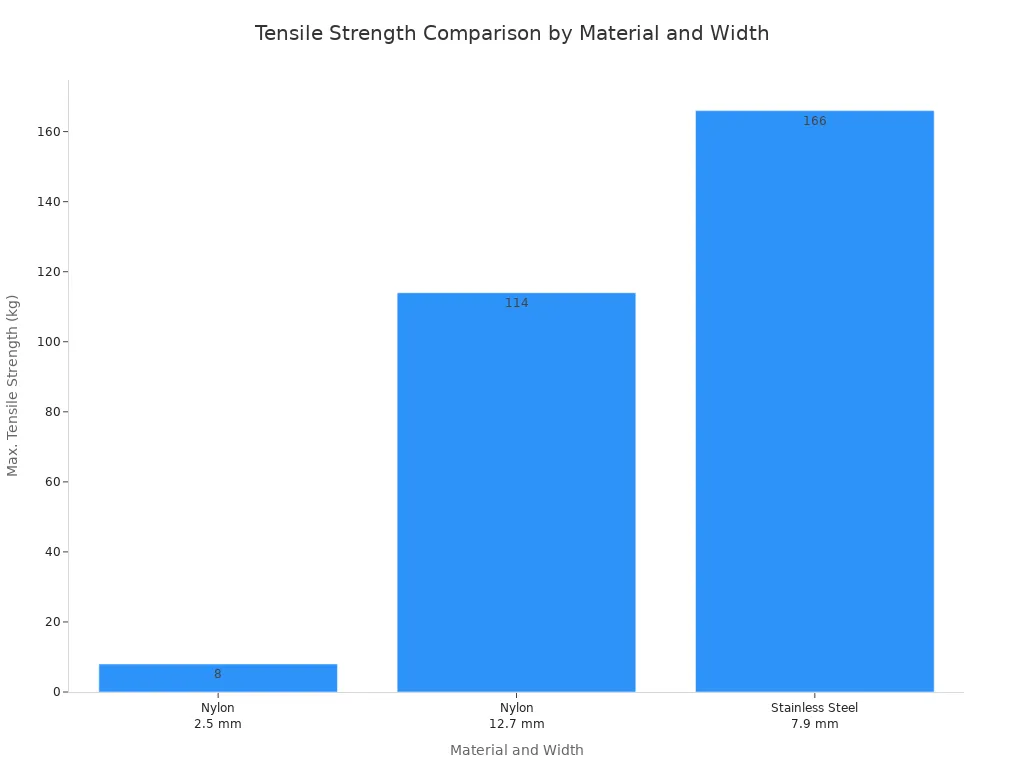

Other metal ties, like aluminum, also have limitations. They may lack the robust strength required for heavy-duty applications. Consider the tensile strength differences. Nylon cable ties, even at their widest (12.7 mm), offer a maximum tensile strength of 114 kg. In contrast, a 7.9 mm wide stainless steel cable tie provides 166 kg of strength. This significant difference highlights the inadequacy of many traditional materials for critical tasks.

| Material | Width (mm) | Max. Tensile Strength (kg) |

|---|---|---|

| Nylon | 2.5 | 8 |

| Nylon | 12.7 | 114 |

| Stainless Steel | 7.9 | 166 |

Unmatched Material Superiority

Stainless steel offers exceptional material superiority. This makes it ideal for challenging conditions. You gain excellent resistance to corrosion, extreme temperatures, and physical stress. For example, 316 stainless steel provides superior corrosion resistance compared to 304 stainless steel. This is especially true in saline environments.

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| General Corrosion Resistance | Good, suitable for various environments including chemicals and moisture. | Superior, especially against chlorides and industrial solvents. |

| Resistance to Chlorides/Saline | Less robust compared to 316. | Significantly enhanced due to molybdenum addition; often called marine-grade. |

| Key Alloying Element for Resistance | - | Molybdenum (enhances resistance to chlorides, pitting, and crevice corrosion). |

| Suitability for Marine Environments | Less preferred. | Preferred due to better resistance to salt (sodium chloride) in seawater. |

316 stainless steel offers vastly superior corrosion resistance to chlorides and acids compared to 304. This makes it a popular choice for coastal environments and areas with high salt levels. You can rely on stainless steel cable ties in these demanding settings.

Stainless steel cable ties also boast impressive temperature versatility. They perform effectively across a wide range. For instance, 14-inch coated 304 stainless steel standard cable ties operate from -112°F to 1000°F. Similarly, 14-inch coated 316 stainless steel UV-resistant standard cable ties are designed for the same -112°F to 1000°F range. This broad operational temperature range ensures reliability where other materials would fail.

The Critical Role of the Self-Locking Mechanism

The self-locking mechanism is a key feature of self-locking stainless steel cable ties. It ensures a secure and lasting hold. This mechanism prevents loosening, even under severe conditions. The reliable ball lock mechanism provides a strong, self-locking grip. It remains secure even with vibration or heavy loads. This durable mechanism ensures a tight hold. It will not loosen over time.

You benefit from this robust design. It ensures uniform pressure across the cable bundle. This minimizes the risk of loosening. It enhances cable performance. It extends the system’s lifespan. Stainless steel cable ties handle high-vibration environments effectively. Their advanced locking mechanisms and vibration-dampening designs ensure stability. They prevent slippage. They reduce stress. This makes them ideal for high-vibration industries.

- Self-locking mechanisms eliminate tool dependency. They ensure secure holds without slippage.

- High tensile strength reduces breakage risks. This improves safety.

- Corrosion resistance and durability ensure long-term performance in harsh environments.

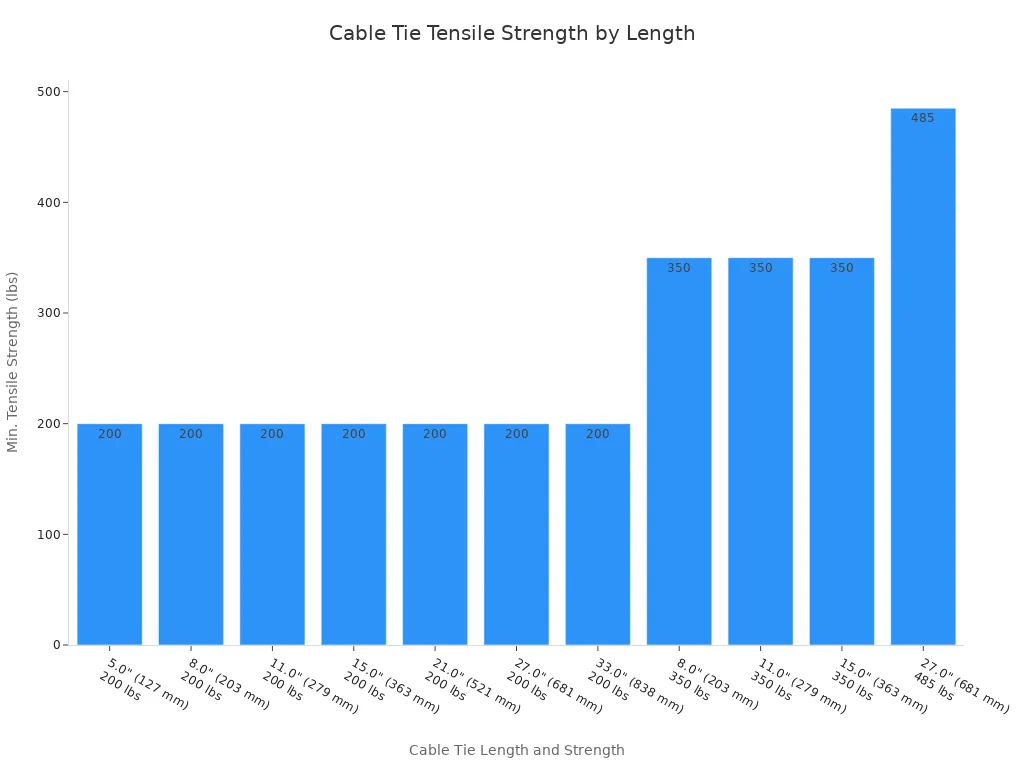

These ties also offer impressive load-bearing capacities. You can find heavy-duty options with up to 485 lbs tensile strength. Standard self-locking stainless steel cable ties typically offer a minimum tensile strength of 200 lbs.

| Length | Min. Tensile Strength |

|---|---|

| 5.0″ (127 mm) | 200 lbs |

| 8.0″ (203 mm) | 200 lbs |

| 11.0″ (279 mm) | 200 lbs |

| 15.0″ (363 mm) | 200 lbs |

| 21.0″ (521 mm) | 200 lbs |

| 27.0″ (681 mm) | 200 lbs |

| 33.0″ (838 mm) | 200 lbs |

| 8.0″ (203 mm) | 350 lbs |

| 11.0″ (279 mm) | 350 lbs |

| 15.0″ (363 mm) | 350 lbs |

| 27.0″ (681 mm) | 485 lbs |

Indispensable Applications for Self-Locking Stainless Steel Cable Ties

You find self-locking stainless steel cable ties essential across many industries. Their unique properties make them indispensable where other fasteners fail. You rely on them for secure, long-lasting performance in the most challenging environments.

Marine and Offshore Environments

Marine and offshore settings present extreme challenges. You face constant exposure to saltwater, high humidity, and harsh UV radiation. Self-locking stainless steel cable ties excel here. They offer superior resistance to corrosion and degradation.

Both 304 and 316L grades provide excellent resistance to rust and corrosion. Unlike plastic alternatives, stainless steel ties do not degrade from prolonged sunlight exposure. For marine or highly corrosive environments, you should use 316L grade stainless steel ties for superior resistance.

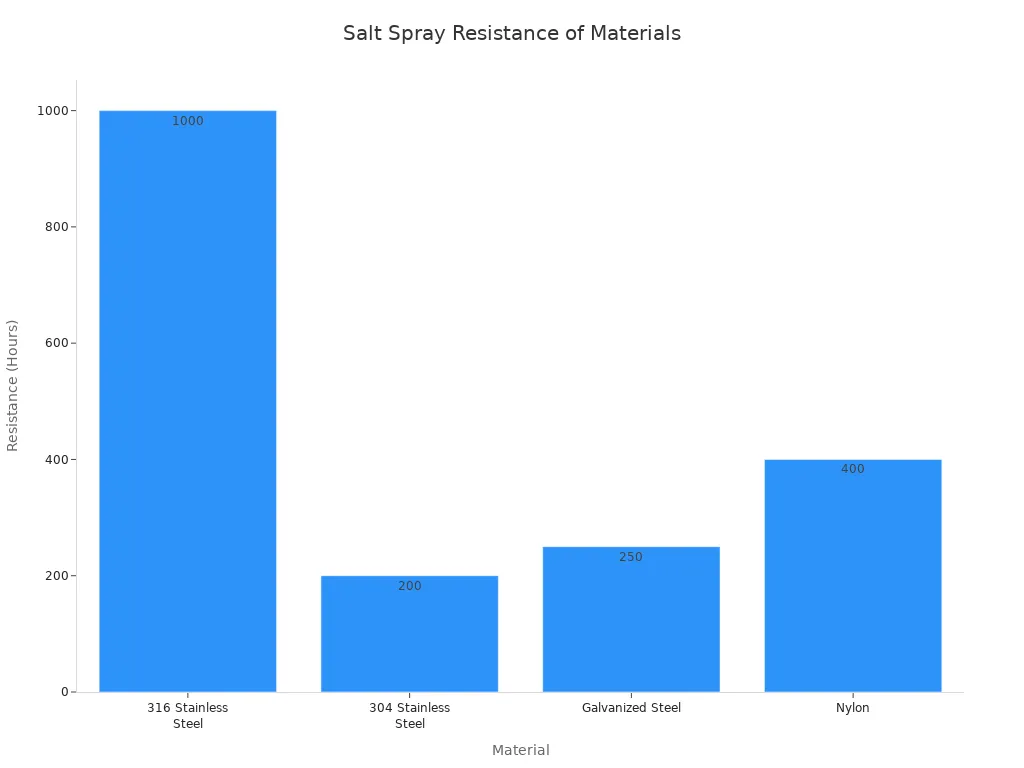

Consider the material differences in saltwater conditions:

| Material | Key Corrosion-Resistant Elements | Salt Spray Resistance (NSS Test) | Failure Mechanism in Marine Environments |

|---|---|---|---|

| 316 Stainless Steel | 2-3% molybdenum (Mo), 16-18% chromium (Cr) | ≥1,000 hours (no red rust) | Surface pitting after 1,200+ hours; repairable via passivation |

| 304 Stainless Steel | No molybdenum, 18-20% chromium | ≤200 hours (severe pitting) | Through-thickness corrosion after 500 hours |

| Galvanized Steel | Zinc coating (8-15μm) | 200-300 hours (zinc layer depleted) | Base metal rusting post-coating failure |

| Nylon | Polymer matrix with UV stabilizers | 300-500 hours (embrittlement) | Cracking due to hydrolysis and UV degradation |

316 stainless steel, specifically AISI 316, contains 2-3% molybdenum (Mo). This significantly enhances its resistance to chloride ion corrosion. Neutral salt spray tests (NSS) confirm its salt spray resistance exceeds 1000 hours. This vastly outperforms 304 stainless steel, which shows severe pitting after 200 hours. This makes 316 stainless steel highly effective in resisting seawater splash, salt spray erosion, and condensation on ship decks, cabins, and offshore facilities. PVDF-coated 316 ties maintain 95% tensile strength after 10,000 hours of UV exposure (ASTM G155).

Marine-grade 316 stainless steel cable ties excel in marine settings. They possess inherent corrosion and rust resistance. They effectively withstand harsh saltwater conditions. They are ideal for outdoor use, resisting UV rays and harsh weather. This ensures long-lasting performance. Unlike nylon ties, which can degrade within months, stainless steel ties can last from 10 to 30 years in outdoor conditions. They maintain strength and flexibility over time. Their material composition prevents UV damage. This ensures reliable performance and suitability for outdoor installations, including resistance to aggressive chemicals.

You must also consider specific certifications for marine applications:

| Standard | Environmental Condition Addressed |

|---|---|

| UL 62275 | Resistance to ultraviolet light, Resistance to corrosion |

| CSA C22.2 No. 62275 | Resistance to ultraviolet light, Resistance to corrosion |

| NMX-J-623-ANCE | Resistance to ultraviolet light, Resistance to corrosion |

| IEC 62275 | Resistance to ultraviolet light, Resistance to corrosion |

Additional certifications ensure compliance and safety:

| Certification/Standard | Requirement/Purpose |

|---|---|

| ASTM B117 | Salt spray tests for corrosion resistance |

| UL flame-retardant and low-smoke toxicity standards | Minimizing harmful gas release during fire, especially for interior use |

| UL94 V-0 | Self-extinguishing properties within 10 seconds without dripping |

| DNV-GL, ABS, Lloyd’s Register | Compliance with classification societies, requiring tests for corrosion resistance, high-temperature durability, and aging resistance |

| UL94 V-0 (Tefzel®) | Flame retardancy, self-extinguishing without harmful emissions during fire |

| Resistance to UV radiation and gamma rays (Tefzel®) | Enhanced durability and stable performance in sunlight or radiation exposure |

Industrial and Manufacturing Settings

Industrial and manufacturing environments often expose fasteners to corrosive chemicals, oils, and extreme temperatures. Self-locking stainless steel cable ties maintain integrity under these conditions.

You find them effective in chemical processing plants within the oil and gas industry. Corrosive chemicals are prevalent there. They resist corrosion caused by these chemicals. This protects cables and equipment from damage. This ensures stable operation of facilities and worker safety. You use them to secure control cables in chemical reactors or fix pipelines carrying corrosive fluids.

Stainless steel cable ties resist various chemicals. These include acids, alkalis, solvents, and oils. This ensures reliable performance in challenging industrial environments. They resist degradation from UV rays, extreme weather, and chemical exposure. This makes them suitable for demanding locations like offshore platforms and industrial plants. Their durability ensures they do not crack even in extreme cold or prolonged sunlight. The passive chromium oxide film provides protection against moisture and chemicals.

Automotive and Aerospace Demands

Automotive and aerospace applications demand fasteners with exceptional vibration resistance, fatigue durability, and temperature stability. You need components that perform flawlessly under dynamic loads and extreme conditions.

Vehicles generate constant vibration and mechanical load cycles. Fasteners with self-locking threads, nylon patches, or locking washers are essential. They maintain preload under dynamic conditions. For fasteners in critical engine assemblies, especially where engine compartments experience vibrations, the material must possess good ductility. This prevents brittle fracture. Automotive fasteners must exhibit high vibration resistance and fatigue durability. Engine and transmission fasteners must withstand high temperatures and torque loads.

In aerospace, you require materials that meet stringent safety and performance standards. Self-locking stainless steel cable ties made from 316 grade stainless steel are ideal for aerospace applications. They offer the necessary strength, corrosion resistance, and temperature stability for critical systems.

Infrastructure and Construction Challenges

Infrastructure and construction projects require robust fastening solutions. You need materials that withstand harsh outdoor elements, heavy loads, and fire risks.

Metal cable ties endure extreme conditions. They resist corrosion from chemicals, oils, and saltwater. This makes them highly durable in marine environments and chemical plants. They maintain functionality under intense temperatures. They have a wide working range of -80°C to +538°C. Furthermore, they are naturally resistant to UV rays and fire. This makes them an ideal choice for outdoor applications with prolonged sun exposure.

You benefit from their exceptional durability and resistance to environmental factors. They offer long-term reliability. They provide high resistance to corrosion, rust, extreme temperatures, and UV radiation. This makes them suitable for outdoor use. They are incredibly strong. They withstand heavy loads and harsh environmental conditions. They maintain integrity and performance across various temperatures, from freezing cold to scorching heat.

Stainless steel epoxy coated cable ties last from 10 to 30 years outdoors. This significantly outperforms plastic ties. They also demonstrate exceptional performance in corrosive environments like coastal areas or chemical facilities. They last up to five years, whereas plastic ties typically degrade within six months.

Stainless steel cable ties significantly enhance fire safety in public infrastructure projects. They comply with updated regulations, specifically BS 7671 of the Electrical Regulations, which came into force on January 1, 2015. These regulations mandate the use of fire-resistant fastenings and fixings for cabling. This prevents premature collapse in extreme heat. Unlike non-metallic alternatives, stainless steel cable ties resist temperatures of approximately 500°C. This high heat resistance ensures wiring systems remain supported during a fire. This remarkably lowers the risk of loose wiring and melting trunking. These are critical safety concerns in public infrastructure.

Food Processing Hygiene Requirements

Food processing environments demand the highest hygiene standards. You need fastening solutions that prevent bacterial growth and contamination.

Fasteners must not harbor bacteria. Smooth and non-porous surfaces are crucial for easy cleaning. They prevent contaminant trapping. The design should minimize crevices where bacteria can accumulate. This includes features like smooth surfaces, minimal voids, and rubber sealing rings. Fasteners must be made of corrosion-resistant materials like stainless steel. They must be easy to clean and maintain. This prevents the build-up of bacteria and contaminants.

Consider these standards for food processing equipment:

| Standard/Requirement | Description |

|---|---|

| Durability | Materials must withstand chemical corrosion, pressures, and temperatures. |

| Compatibility | Materials must be compatible with cleaning solutions, SIP conditions, and bioprocessing conditions, adhering to ASME BPE guidelines. |

| Homogeneity | Surfaces exposed to SIP cleaning or fluids must be nonabsorbent, impervious, inert, nontoxic, corrosion and scratch-resistant, insoluble, and naturally homogeneous. |

| Cleanability | Equipment must respond well to surface cleaning, without imperfections. Fasteners and threads should avoid exposure to cleaning solutions, and bolted attachments should be minimized. |

| Drainability | Systems must be designed for gravity drainage, with continuous pitch as specified by ASME BPE standards, to remove bioburdens. |

| Additional Requirements | Specific considerations for Clean-in-Place (CIP) systems, including lubricant availability and exterior design for frequent washing. |

Stainless steel is non-porous. This prevents the absorption of bacteria, moisture, or contaminants. This simplifies cleaning and sanitization. It inhibits bacterial growth. It resists corrosion and harsh chemicals like strong disinfectants, degreasers, and food-grade sanitizers. Many plastics degrade and release micro-particles. Stainless steel cable ties are non-shedding. This eliminates the risk of particles contaminating food products. This is a common issue with degrading plastic ties. Grade 316 stainless steel is specifically highlighted for its durability, chemical resistance, and compliance with food safety standards. This makes it ideal for food processing environments.

You find self-locking stainless steel cable ties indispensable in harsh environments. Their superior material properties and robust self-locking mechanism deliver unmatched durability. They resist extreme conditions. You achieve secure, long-lasting fastening where other solutions fail. This guarantees safety, reliability, and operational continuity.

FAQ

What makes stainless steel cable ties superior to plastic in harsh environments?

You find stainless steel ties offer unmatched durability. They resist extreme temperatures, UV radiation, and corrosive chemicals. Plastic ties degrade under these conditions.

Which grade of stainless steel cable tie should you use for marine applications?

You should choose 316L stainless steel cable ties. This grade contains molybdenum. It provides superior resistance to saltwater and chloride corrosion.

Can these cable ties withstand extreme temperatures?

Yes, you can rely on them in extreme heat or cold. They operate effectively from -112°F to 1000°F. This ensures consistent performance.

Post time: Nov-27-2025