Professionals seek durable solutions for critical applications. This post explores the most robust self-locking stainless steel cable ties for 2025. These ties provide superior strength, exceptional corrosion resistance, and secure fastening. The article details the top 10 options. They perform reliably in demanding environments.

Key Takeaways

- Stainless steel cable ties are very strong. They work well in hot or cold places. They do not rust easily.

- These ties have a special lock. It keeps them tight. This stops things from coming loose.

- Many jobs use these ties. They are good for factories, boats, and cars. They keep wires and parts safe.

Understanding Self-Locking Stainless Steel Cable Ties

Why Stainless Steel for Durability

Stainless steel offers unmatched durability for cable ties. Its material strength is significant. Grades 304 and 316 provide approximately 600 MPa (150 lbs) tensile strength. Some ties even reach 250 lbs, suiting demanding tasks. Stainless steel also resists various forms of corrosion. This includes pitting, stress corrosion cracking, and galvanic corrosion. The ASTM G48 standard confirms their integrity in harsh settings like marine environments. Furthermore, these ties tolerate extreme temperatures. They operate effectively from -328°F to 1000°F (-80°C to +538°C). This wide range ensures performance in high heat or extreme cold. In contrast, non-stainless steel ties often fail in harsh, moist conditions. They absorb water, become brittle, and lose locking strength. They can also corrode if they have metal parts, and are prone to mold and mildew growth.

Key Features of Self-Locking Mechanisms in Cable Ties

Self-locking mechanisms are crucial for secure fastening. These integrated systems within the tie head grip the tail once inserted. Common mechanisms include a ratchet-style tooth, which allows one-way movement. Stainless steel ties often feature a ball bearing system. This wedges the tie’s tail securely in place. Roller-locking devices also exist for higher tensile loads. Once the tail passes through the head, it cannot slide back. This creates a tight, reliable grip. It resists loosening even under vibration or tension. These mechanisms prevent slippage and unwanted movement. They maintain consistent tension, reducing accidental disconnections.

Applications Benefiting from These Self-Locking Stainless Steel Cable Ties

Many industries rely on self-locking stainless steel cable ties for critical applications. Industrial facilities use them to secure machinery, cable trays, and HVAC systems. They withstand high temperatures, oil, and vibration. In marine and offshore environments, these ties resist corrosive air and meet shipbuilding standards. The oil and gas sector bundles cables in high-temperature, high-pressure areas. They enhance safety with fire resistance. Automotive and transportation industries secure wiring harnesses and exhaust systems. These ties maintain integrity under vibration, extreme temperatures, and chemical exposure. Telecommunications and data centers also use them for reliable cable management.

Top 10 Self-Locking Stainless Steel Cable Ties for 2025

This section highlights the leading self-locking stainless steel cable ties available in 2025. These products offer exceptional performance and reliability across various demanding applications.

Thomas & Betts Ty-Rap Stainless Steel Cable Ties

Thomas & Betts Ty-Rap cable ties are renowned for their robust construction. They often feature a 316-grade stainless steel locking barb. This design provides impressive tensile strengths. For instance, some Ty-Rap cable ties achieve up to 780N (approximately 175 lbs) for demanding applications. Other variations, like the Ty-Rap® Cable Tie made from 304 Stainless Steel, offer a 100 lbs (445 Newtons) tensile strength. Heavy-duty options can reach 300 lbs, while light-duty versions provide 150 lbs. These ties are suitable for high-performance and UV-resistant needs.

Panduit Pan-Steel Self-Locking Stainless Steel Cable Ties

Panduit Pan-Steel self-locking stainless steel cable ties are engineered for extreme conditions. They boast a usable life exceeding 30 years. These ties withstand extreme temperatures, hazardous chemicals, and intense vibration. Their smooth, round edges prevent damage to cable insulation. They also protect technicians from injuries. Panduit Pan-Steel ties maintain high retained tension for tight fastening in harsh environments. They meet and exceed stringent industry standards. These ties offer superior strength, durability, and cost-effectiveness. They provide reliable system performance with resistance to chemicals, vibration, radiation, weathering, and extreme temperatures.

| Material | Loop Tensile Strength | UV Resistance | Extreme Temps | Salt Spray | Chemicals | Contact with Aluminum | Flammability |

|---|---|---|---|---|---|---|---|

| 304 Stainless Steel | Best | Best | Best | Good | Better | Not Recommended | None |

| 316 Stainless Steel | Best | Best | Best | Best | Best | Not Recommended | None |

| Coated 316 Stainless Steel | Better | Good | Better | Good | Good | Best | UL94V-2 |

These ties are suitable for both indoor and outdoor environments, offering excellent UV resistance.

DEI Titanium Self-Locking Stainless Steel Cable Ties

DEI Titanium self-locking stainless steel cable ties are constructed from high-grade 304 or 316 stainless steel. They withstand extreme heat, in excess of 2500 degrees F. These ties typically offer a 100 lb tensile strength. They feature a ball-lock mechanism, which is rustproof and vibration-resistant. This design ensures fast and secure installation. DEI ties resist acids, alkalis, oils, oil derivatives, grease, chemicals, seawater, corrosion, and UV radiation. They operate effectively from -60 °C to +600 °C. Common applications include securing exhaust wrap, bundling wires, bundling hoses, and bundling other insulation products.

| Feature/Specification | Detail |

|---|---|

| Construction Material | High Grade 304 Stainless Steel |

| Heat Withstand | In Excess of 2500 Degrees F |

| Tensile Strength | 100 lb |

| Clip Material | Stainless Steel 304 |

| Clip Type | Locking |

| Color | Steel |

| Length | 8 in |

| Material | Stainless Steel 304 |

| Package Quantity | 8 |

Advanced Cable Ties (ACT) Stainless Steel Cable Ties

Advanced Cable Ties (ACT) offers stainless steel cable ties ideal for extreme conditions and harsh environments. They withstand corrosive and saltwater exposure, chemicals, and radiation. These ties feature a ball locking mechanism for easy insertion. Some versions include a polyester coating. This coating acts as a barrier to prevent corrosion between dissimilar metals. ACT ties are suitable for both indoor and outdoor use. For example, a black polyester stainless steel 316 tie offers a 150 lb (665 Newtons) tensile strength. It has a maximum operating temperature of 302°F (150°C) and a minimum of -76°F (-60°C).

Gardner Bender Stainless Steel Cable Ties

Gardner Bender stainless steel cable ties provide reliable fastening solutions. They are made from 304 stainless steel, giving them a silver color. These ties are available in lengths such as 6.1 inches and 11 inches. They offer a 100 lb tensile strength. Gardner Bender ties resist chemicals, radiation, and extreme temperatures. They are suitable for harsh, corrosive, saltwater, and clean environments, such as food processing facilities. Their self-locking ball mechanism ensures low insertion force and high tensile strength.

L.A. Woolley Electric Heavy-Duty Stainless Steel Cable Ties

L.A. Woolley Electric provides heavy-duty stainless steel cable ties designed for robust applications. These ties offer superior strength and durability. They are ideal for securing large bundles or in environments requiring extra resilience. Professionals trust L.A. Woolley Electric for reliable fastening solutions in industrial settings.

Xinjing Industrial Grade Self-Locking Stainless Steel Cable Ties

Xinjing, based in Ningbo, China, specializes in industrial-grade stainless steel products. Their self-locking stainless steel cable ties benefit from extensive expertise in stainless steel processing and customization. Xinjing provides various cold-rolled and hot-rolled stainless steel materials, including 200, 300, and 400 series, duplex steel, and heat-resistant steel. This background ensures their cable ties meet stringent industrial demands. They offer robust performance for diverse applications, leveraging their comprehensive material knowledge and processing capabilities.

Gordon Electric High-Tensile Stainless Steel Cable Ties

Gordon Electric offers high-tensile stainless steel cable ties with extensive customization options. They provide various core materials to suit specific environmental needs.

| Feature Category | Specific Customization | Key Specifications/Parameters |

|---|---|---|

| Core Material | 201 Stainless Steel | Cost-effective, for dry indoor environments |

| 304 Stainless Steel | 8% nickel, salt spray resistance ≥48h, for outdoor/general industrial use | |

| 316 Stainless Steel | 2-3% molybdenum, salt spray resistance ≥1000h, for marine/chemical anti-corrosion | |

| 316L Stainless Steel | Enhanced low-temperature toughness, for cold regions | |

| Bimetal Composite | Inner 304 core + outer 316 anti-corrosion layer, balances performance/cost | |

| Inconel Alloy | Temperature resistance ≥600℃, for ultra-high temperature scenarios | |

| Surface Treatment | Epoxy-Coated | Thickness 0.1-0.3mm, temp resistance -40℃ to 180℃, insulation resistance >10⁶Ω |

| Nylon 11-Coated | Friction coefficient reduced by 40%, scratch-proof for precision cables | |

| Teflon-Coated | Surface energy 18 dyn/cm, anti-stick and anti-corrosion | |

| Natural Whitened | Chemical passivation/sandblasting, improved basic rust resistance | |

| Mirror-Polished | Mechanical/electrochemical polishing, long-term gloss retention | |

| Colored | Ion deposition/high-temp oxidation, customizable colors | |

| Powder-Coated | Coating thickness 1-1.5mm, for heavy-duty equipment protection | |

| PVC-Coated | Coating thickness 0.65-0.75mm, balances flexibility and anti-corrosion | |

| Size & Structure | Narrow-Width | 2-4mm width, for small electronic cable bundling; tensile strength +20% per 1mm width increase |

| Extra-Long | 2000-3000mm length, tolerance ±0.5mm, for large-diameter pipeline fixing | |

| Thick-Wall High-Strength | 0.8-1.0mm thickness, tensile strength up to 1500N, for heavy-component fastening |

These options allow for precise selection based on application requirements.

Store House (Harbor Freight) Stainless Steel Cable Ties

Store House, a brand often found at Harbor Freight, offers stainless steel cable ties for general-purpose and light industrial use. These ties provide a cost-effective solution for various bundling needs. They offer basic corrosion resistance and strength suitable for less extreme environments. Users often choose them for their accessibility and practical utility in workshops and home projects.

Strong Ties Industrial Self-Locking Stainless Steel Cable Ties

Strong Ties provides industrial self-locking stainless steel cable ties known for their exceptional strength and durability. They are UL Listed, File No. E530766, and meet UL Standard UL 62275 TYPE 2. These ties are made from Type 304 or 316 stainless steel. They operate from -112ºF (-80ºC) to +572ºF (300ºC) and have a maximum failure temperature of 1000ºF (537ºC). Strong Ties offer excellent UV and chemical resistance. They are flame retardant, non-toxic, and non-flammable. Installation requires no special tools, and rounded edges ensure safer handling. Minimum tensile strength for some lengths is 200 lbs. These ties are ideal for mining, pulping, chemical plants, and other demanding applications with corrosion, vibration, weathering, radiation, and temperature extremes.

| Feature | Specification |

|---|---|

| UL Listing | UL Listed, File No. E530766 Positioning Device 33AS, UL Standard UL 62275 TYPE 2 |

| Material | Type 304 Stainless Steel |

| Operating Temperature | -112ºF (-80ºC) to +572ºF (300ºC) |

| Max Failure Temperature | 1000ºF (537ºC) |

| Plenum Rating | AH-1 |

| Flammability | Flame Retardant & Non-Toxic, Non-Flammable |

| UV Resistance | Excellent |

| Chemical Resistance | Excellent |

| Installation | No Tools Required, Rounded Edges for Safer Handling |

| Tensile Strength (Min.) | 200 lbs (for 5.0″ and 8.0″ lengths) |

| Strap Width | 0.18″ (4.6 mm) |

| Max Bundle Diameter | 1″ (25.4 mm) for 5.0″ length, 2″ (50.8 mm) for 8.0″ length |

| Head Width | 0.26″ (6.5 mm) |

| Package Quantity | 100 |

| Applications | Mining, pulping, chemical plants, demanding applications with corrosion, vibration, weathering, radiation, temperature extremes |

Factors to Consider When Choosing Your Self-Locking Stainless Steel Cable Ties

Selecting the correct self-locking stainless steel cable ties ensures long-term performance and safety. Several factors guide this decision.

Material Grade (e.g., 304 vs. 316 Stainless Steel)

The choice between 304 and 316 stainless steel is critical. 304 stainless steel cable ties suit most general applications. They provide strong, durable bundling in indoor and outdoor environments with minimal exposure to harsh chemicals or saltwater. Conversely, 316 stainless steel cable ties excel in environments needing enhanced corrosion resistance, especially against chlorides. This makes them ideal for marine environments, chemical processing plants, and coastal areas. The addition of molybdenum in 316 stainless steel significantly boosts its resistance to chlorides, sea salt, and aggressive chemicals. For less aggressive environments, 304 stainless steel offers a cost-effective and durable solution.

Tensile Strength Requirements for Self-Locking Stainless Steel Cable Ties

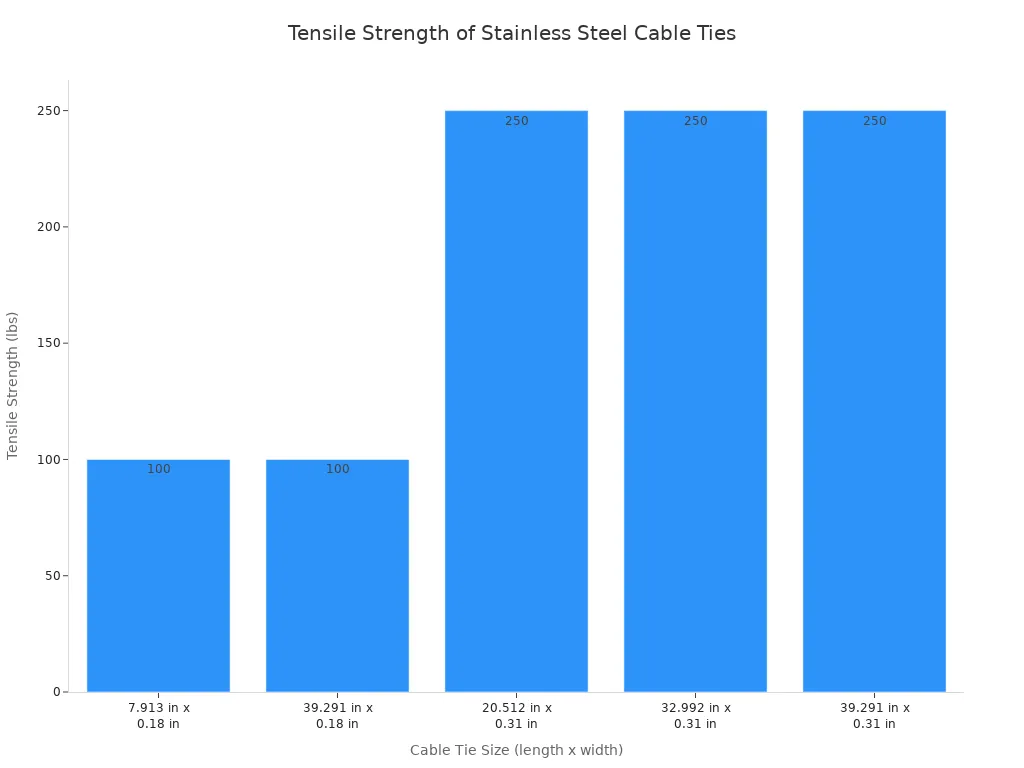

Tensile strength indicates the maximum load a cable tie can withstand before breaking. Cable tie width and thickness directly influence this strength. Wider and thicker ties inherently possess higher tensile strength. Industry standards, such as UL/IEC 62275, define minimum tensile strengths. For example, a 7.913 in x 0.18 in tie requires 100 lbs, while a 20.512 in x 0.31 in tie needs 250 lbs.

| Cable Tie Size (length x width) | Minimum Loop Tensile Strength |

|---|---|

| 7.913 in x 0.18 in | 100 lbs |

| 39.291 in x 0.18 in | 100 lbs |

| 20.512 in x 0.31 in | 250 lbs |

| 32.992 in x 0.31 in | 250 lbs |

| 39.291 in x 0.31 in | 250 lbs |

Operating Temperature Range

Stainless steel cable ties offer superior temperature tolerance. They operate effectively from -80°C to +540°C. This wide range ensures integrity in diverse weather conditions, including extreme cold and hot summers. They maintain their locking mechanism and structural integrity in high-temperature environments like refineries and foundries where plastic ties would degrade.

Environmental Resistance (UV, Chemical, Corrosion)

Environmental factors significantly impact cable tie longevity. Stainless steel cable ties offer excellent resistance to weather conditions, UV radiation, and aggressive chemicals. Type 316 stainless steel exhibits superior corrosion resistance in environments with various chemicals, salts, and acids. Coated stainless steel cable ties are virtually unaffected by UV radiation, making them suitable for long-term outdoor use.

Installation Tools and Ease of Use

Proper installation ensures maximum performance. Specialized tools, often called ‘Stainless Steel Cable Tie Tensioning & Cutting Tools,’ are recommended. These tools fasten and simultaneously cut ties cleanly without leaving sharp edges. Using a tensioning tool ensures precise and controlled tension application, preventing over-tightening or under-tensioning. This practice guarantees secure fastening and prevents tie failure.

Selecting the right self-locking stainless steel cable ties is crucial for long-term durability and security. The 10 options presented offer robust performance, meeting diverse fastening needs. Their exceptional longevity reduces maintenance costs, providing significant lifetime savings. Professionals find these ties invaluable due to their strength, versatility, and cost-effectiveness.

FAQ

Are Xinjing’s self-locking stainless steel cable ties reusable?

No, you should not reuse them. The engineered self-locking mechanism provides a permanent, secure hold. Releasing it can weaken the tie, compromising its reliability.

What is the main difference between 304 and 316 stainless steel cable ties?

316 stainless steel includes molybdenum. This enhances corrosion resistance, especially against chlorides. 304 stainless steel suits general applications.

Do self-locking stainless steel cable ties require special tools for installation?

Professionals recommend specialized tensioning and cutting tools. These tools ensure proper tension and a clean cut. This prevents sharp edges.

What are the primary benefits of using stainless steel cable ties over plastic ones?

Stainless steel ties offer superior strength, extreme temperature resistance, and excellent corrosion resistance. They provide long-term durability in harsh environments.

Post time: Dec-04-2025